Octenyl succinic starch ester preparation method

A technology of octenyl succinic acid and octenyl succinic anhydride, applied in the field of food chemistry, can solve the problems of long reaction time, high process condition control requirements, difficult quality control, etc., and achieves high reaction efficiency and shortened reaction time. , the preparation method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

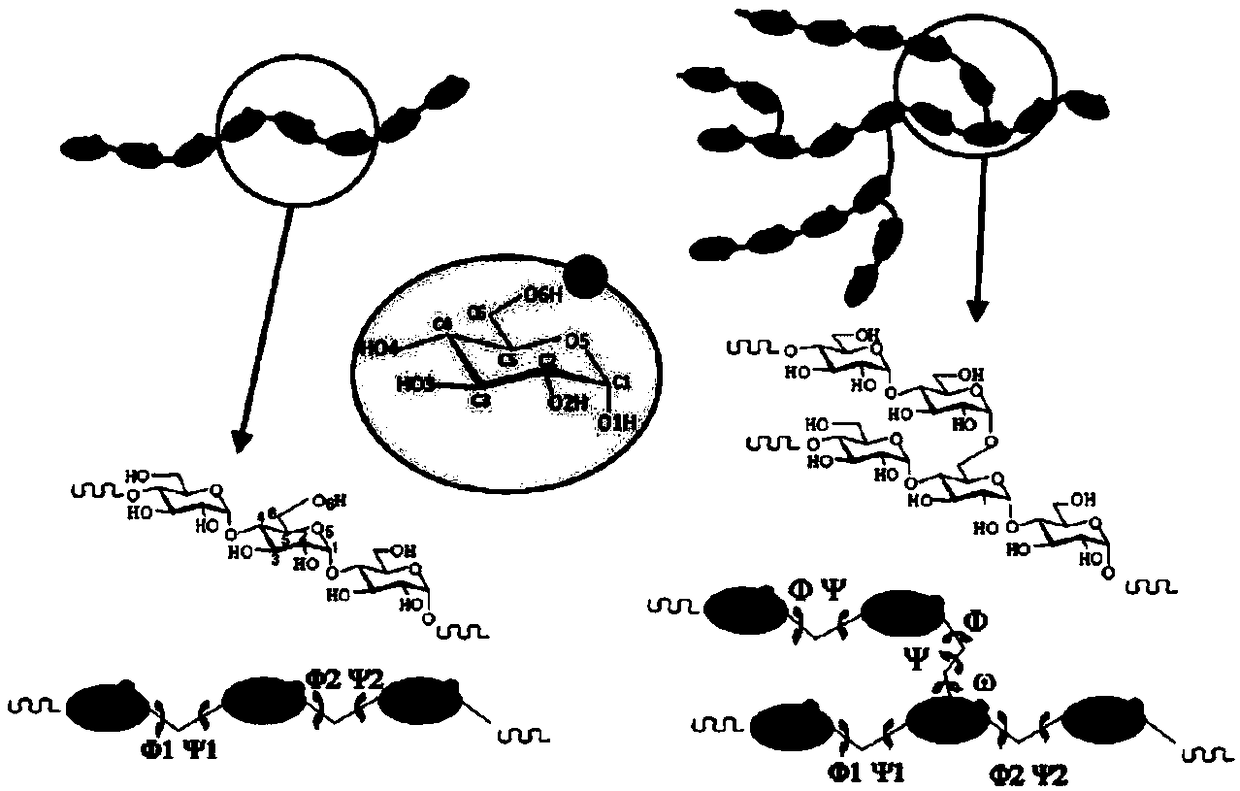

Image

Examples

Embodiment 1

[0039]1) Add 10kg of sweet potato starch to 30kg of water for homogeneous dispersion, and use 1mol / L sodium hydroxide solution to adjust the pH to 7.5 to obtain an alkaline dispersion of starch; dissolve 0.1kg of octenyl succinic anhydride in 1kg of α-linolenic acid to obtain Greasy dispersion of octenyl succinic anhydride.

[0040] 2) Control the steam temperature in the ejector to 160°C, pump the alkaline starch milk and octenyl succinic anhydride dispersion liquid into the ejector at the same time according to the feeding ratio for jet cooking, the total feed rate is 100kg / h, and obtain the cooking liquid;

[0041] 3) The obtained cooking liquid is left to stand for stratification, and 1.001 kg of the upper oil phase is recovered. After testing, the water content of the oil phase is 0.12%, and the saponification rate of α-linolenic acid is 0.11%, which can be directly recovered and used mechanically. Add 50KU of α-amylase to the lower emulsion, and carry out enzymatic hydr...

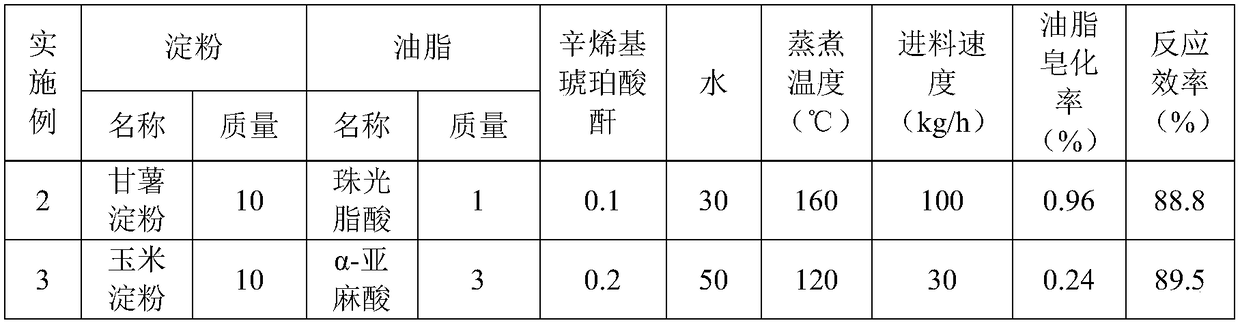

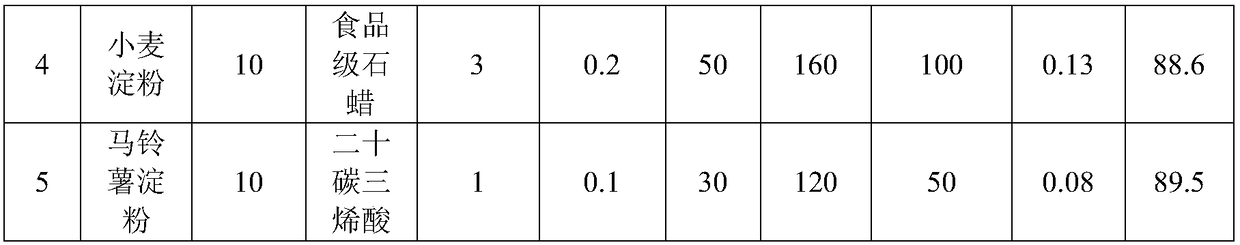

Embodiment 2-5

[0044] According to the method of Example 1, parameters such as the type and amount of starch used, the type and amount of oil used, the amount of octenyl succinic anhydride and water used, the cooking temperature, and the feed rate were adjusted. Other conditions were the same as in Example 1, and the results were obtained. As follows (the mass unit in the table is kg):

[0045]

[0046]

Embodiment 6

[0048] 1) Add 10kg of sweet potato starch into 50kg of water for homogeneous dispersion, and adjust the pH to 8 to obtain an alkaline dispersion of starch; dissolve 0.3kg of octenyl succinic anhydride and 0.15kg of Span 60 in 5kg of α-linolenic acid to obtain octane Greasy dispersion of alkenyl succinic anhydride.

[0049] 2) Control the steam temperature in the injector to 160°C, pump the alkaline starch milk and octenyl succinic anhydride dispersion liquid into the injector at the same time according to the feeding ratio, and perform jet cooking at a feed rate of 100kg / h to obtain a cooking liquid;

[0050] 3) The obtained cooking liquor was allowed to stand for stratification, and 5.25 kg of the upper oil phase was recovered. After testing, the water content of the oil phase is 2.06%, and the saponification rate of α-linolenic acid is 0.89%, which can be directly recovered and used mechanically. Add 400KU of α-amylase to the lower emulsion, and carry out enzymatic hydrolys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com