High-tightness flow battery

A high-level flow battery technology, applied in secondary batteries, regenerative fuel cells, circuits, etc., can solve problems such as large contact resistance of flow batteries, reduce battery internal resistance, improve battery voltage efficiency, and increase battery energy. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

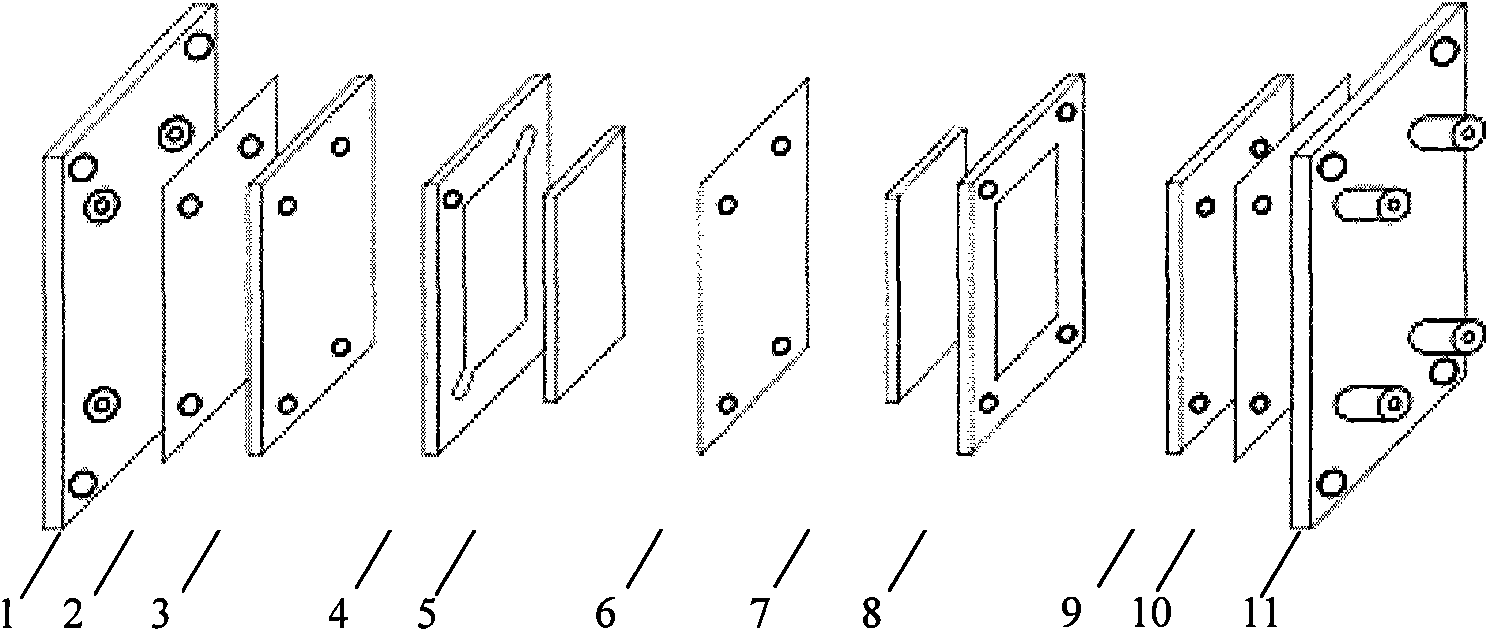

[0019] Description of parts used:

[0020] End plate: PVC material, 3cm thick

[0021] Current collector (single collector plate): isostatic high-density graphite plate, thickness 6mm

[0022] Positive electrode: polyacrylonitrile-based graphite felt, thickness 5mm, produced by Hunan Jiuhua Carbon Co., Ltd.

[0023] Negative electrode: Polyacrylonitrile-based graphite felt with a thickness of 5mm, Hunan Jiuhua Carbon Co., Ltd.

[0024] Liquid flow frame: sheet polyurethane, thickness 5mm

[0025] Proton exchange membrane (diaphragm): homogeneous cation exchange membrane (domestic PE-01), thickness 0.3mm

[0026] Conductive adhesive: ZY518 graphite filled conductive adhesive, produced by Zhuoyi Chemical

example 1

[0029] The flow frames 4, 8 and the membrane 6 of the flow battery are bonded side by side and in parallel with the adhesive, the outer edge of the membrane 6 overlaps with the edge of the outer frame of the flow frame, and the bonding part of the adhesive is the outer edge of the membrane and the liquid flow frame. The outer edge of the outer frame of the flow frame; the shape and size of the electrodes 5 and 7 are the same as those of the inner frame of the flow frame 4 and 8, the electrodes 5 and 7 are embedded in the flow frame, and the membrane 6 and the electrodes 5 and 7 pass through Conductive adhesives are bonded side by side in parallel to form an integrated structure.

[0030] The liquid flow frames 4, 8 and the film 6 are bonded with epoxy resin, and the electrodes 5, 7 and the film 6 are bonded with graphite-filled conductive adhesive. In this device, the outer frame of the liquid flow frame is 80mm×70mm, the inner frame is 40mm×40mm, and the thickness of the liqu...

example 2

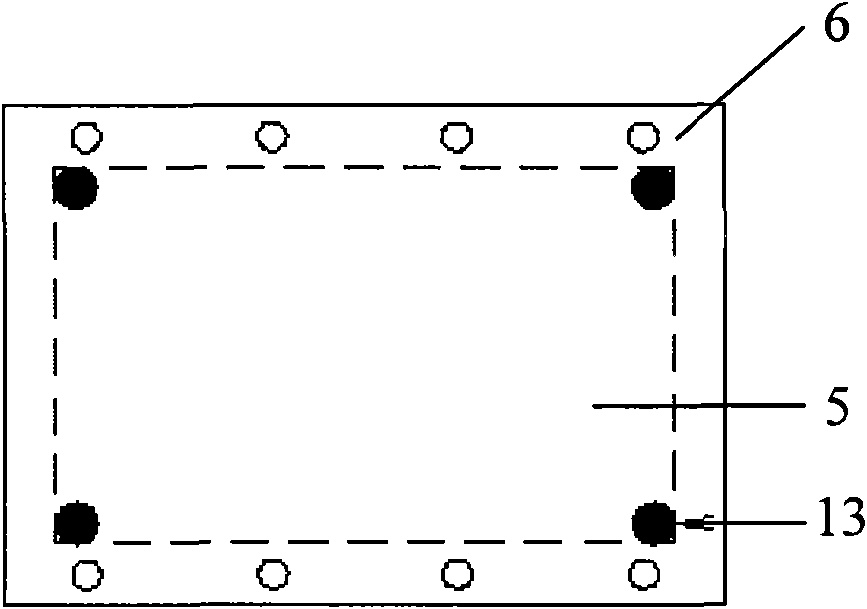

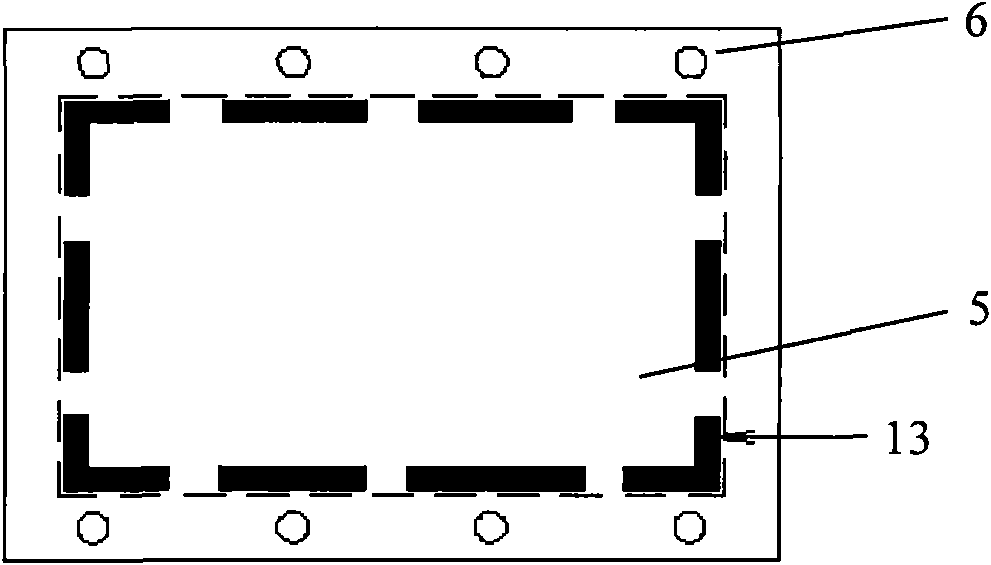

[0032] In this embodiment, epoxy resin and polyamide resin are used for the bonding of liquid flow frames 4, 8 and membrane 6 in a volume ratio of 1:0.1 to 10 and are evenly mixed as an adhesive for bonding. Graphite-filled conductive adhesives are used for bonding. In this device, a homogeneous positive membrane is used with a thickness of 0.3mm. The outer frame of the flow frame is 370mm×270mm, the inner frame is 320mm×210mm, and the thickness of the flow frame is 5mm; the effective area of the electrode is 320mm×210mm. The thickness is 5mm, and the electrode and the film are bonded with conductive glue. The conductive glue is coated on the film with four sides 13 (the way of combining dots and lines), close to the outer edge of the electrode, and the dotted line indicates the outer edge of the electrode (See image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com