Staged fracturing sliding sleeve used for oil well and device and usage method thereof

A segmented fracturing technology for sliding sleeves and oil wells, which is applied to wellbore/well valve devices, earthwork drilling, wellbore/well components, etc. It can solve problems affecting the normal operation of sliding sleeves and improve the effective oil flow area, ensuring high-efficiency mining, and increasing the effect of sealing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

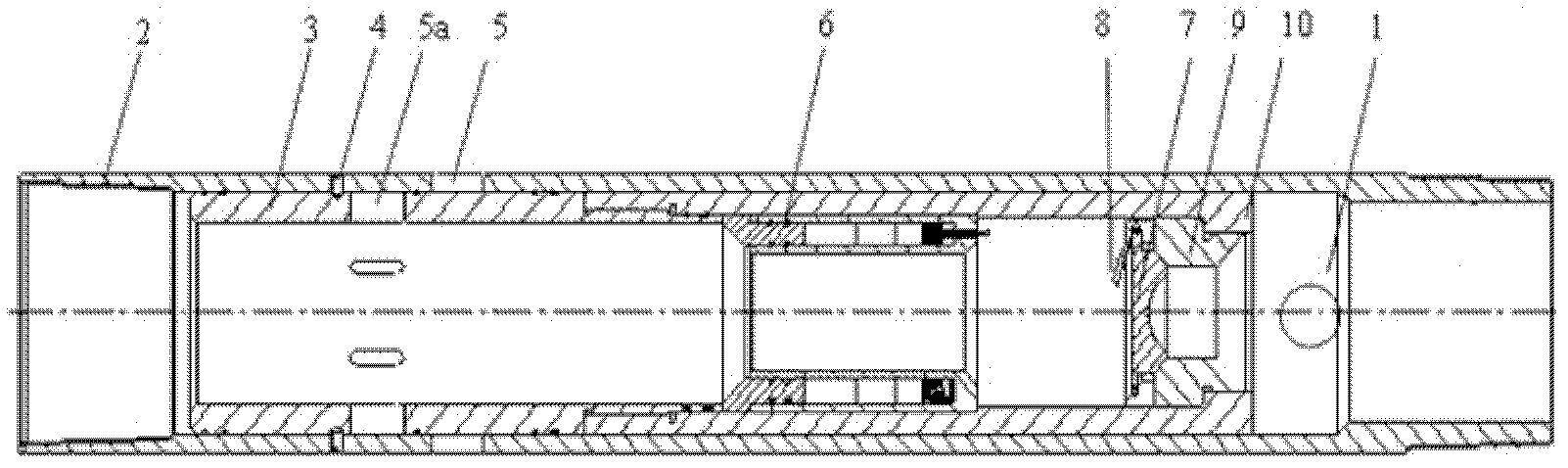

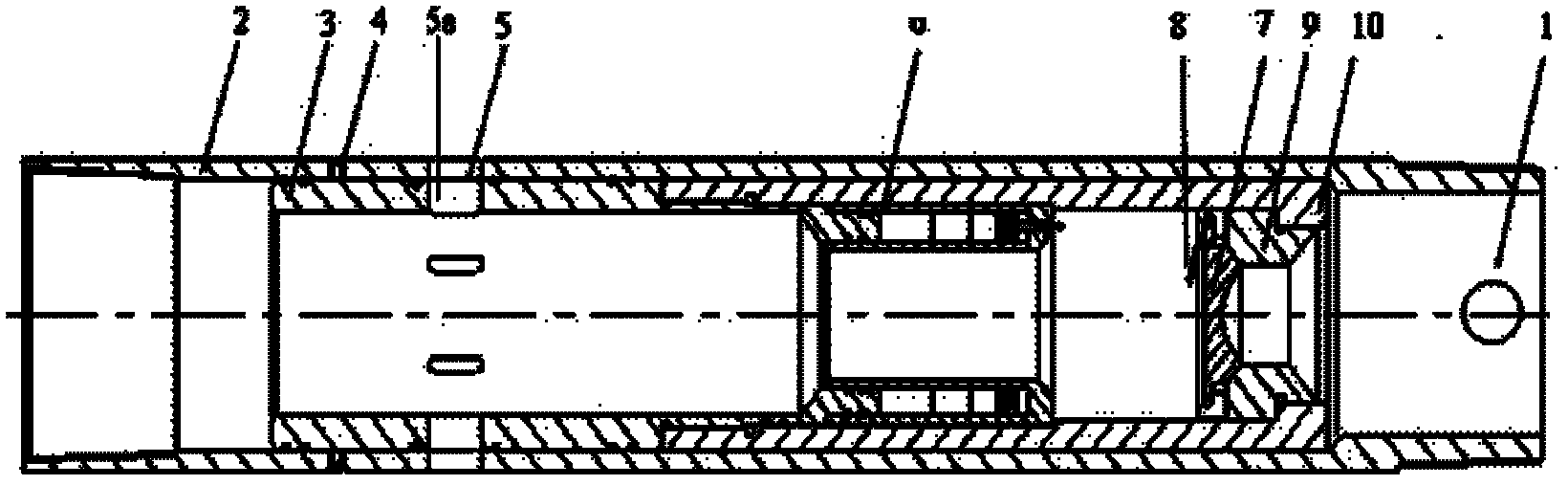

[0036] The structural composition and functional principles of the present invention will be further described below in conjunction with the accompanying drawings. Although the following are only described with reference to exemplary embodiments, these exemplary embodiments are not intended to limit the scope of the present invention, and there may be many alternatives, modifications and variations that will be obvious to those skilled in the art. Accordingly, the intended claimed subject matter of the present invention encompasses various modifications and alterations apparent to those skilled in the art.

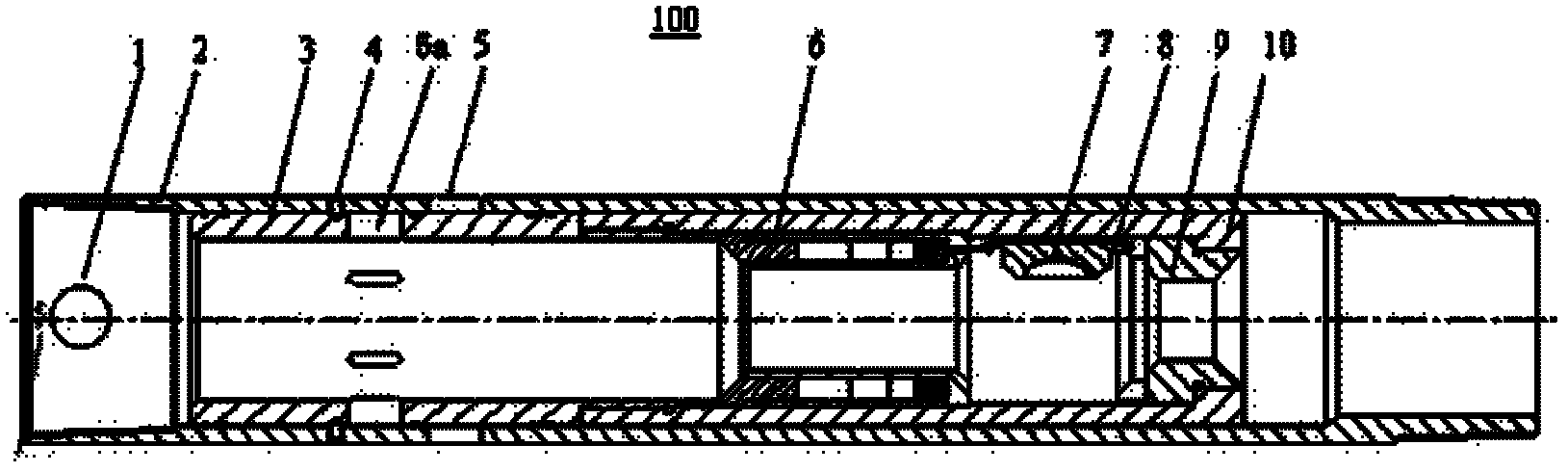

[0037] Such as figure 1 As shown, the induction sliding sleeve 100 according to the present invention has a casing 2, and casing buckles capable of being connected with the oil casing can be respectively processed at both ends of the casing. A fracturing hole 5 is opened on the side wall of the casing 2 . The induction sliding sleeve 100 also includes an inner sliding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com