Super large truss type floating maine platform

A floating platform, truss-type technology, applied in the direction of floating buildings, etc., can solve the problems of complex platform structure and operation, complex structure and operation, increased volume and self-weight, etc. Less, the effect of dispersing the applied load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

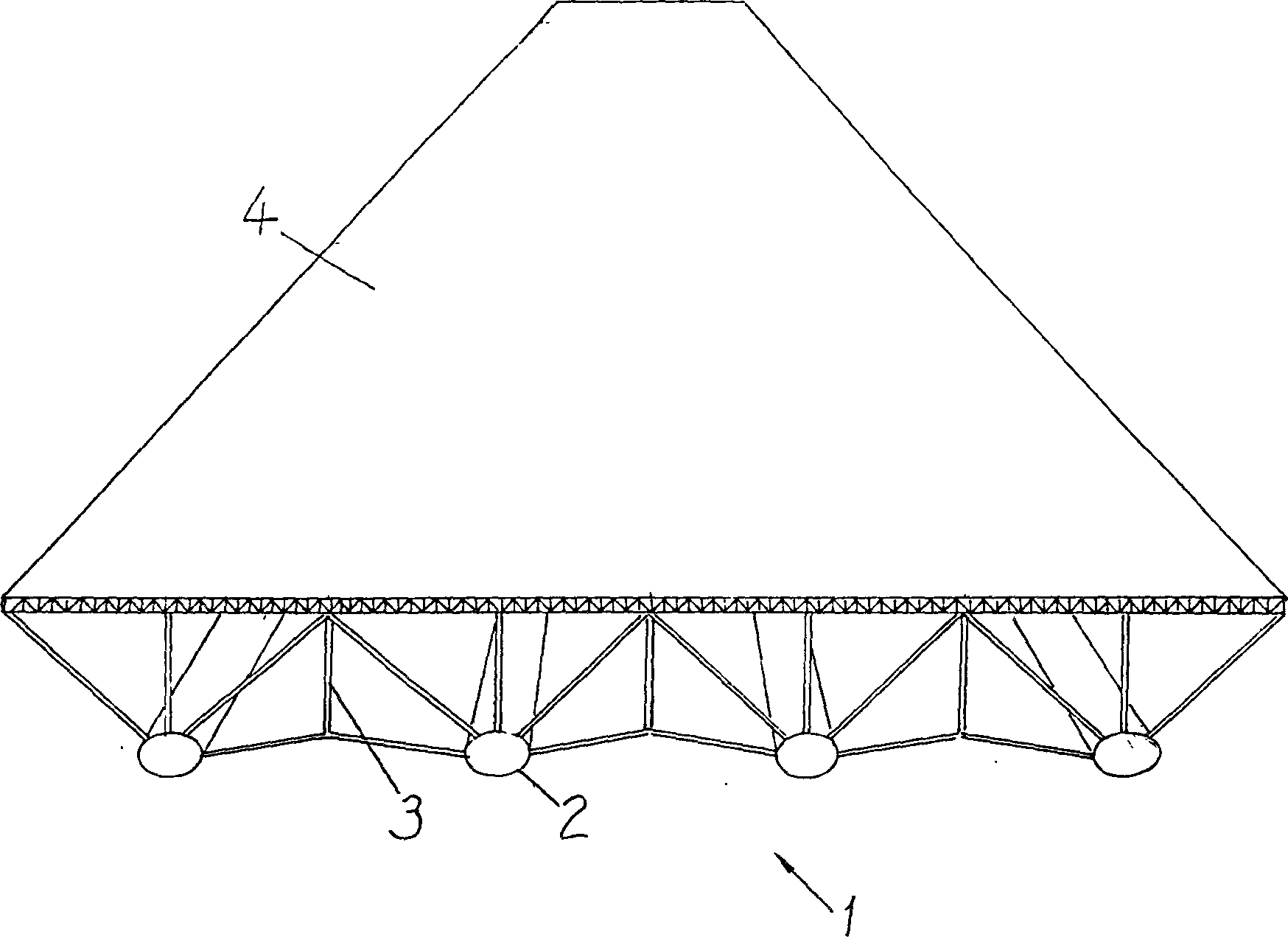

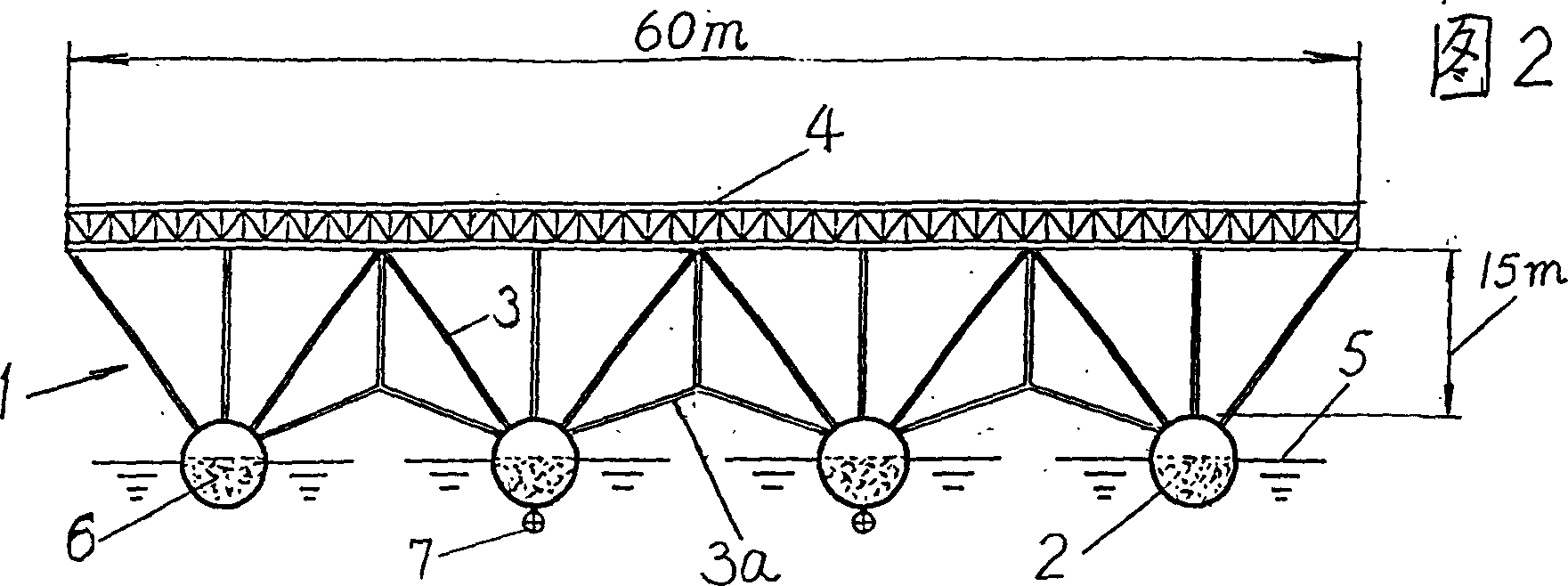

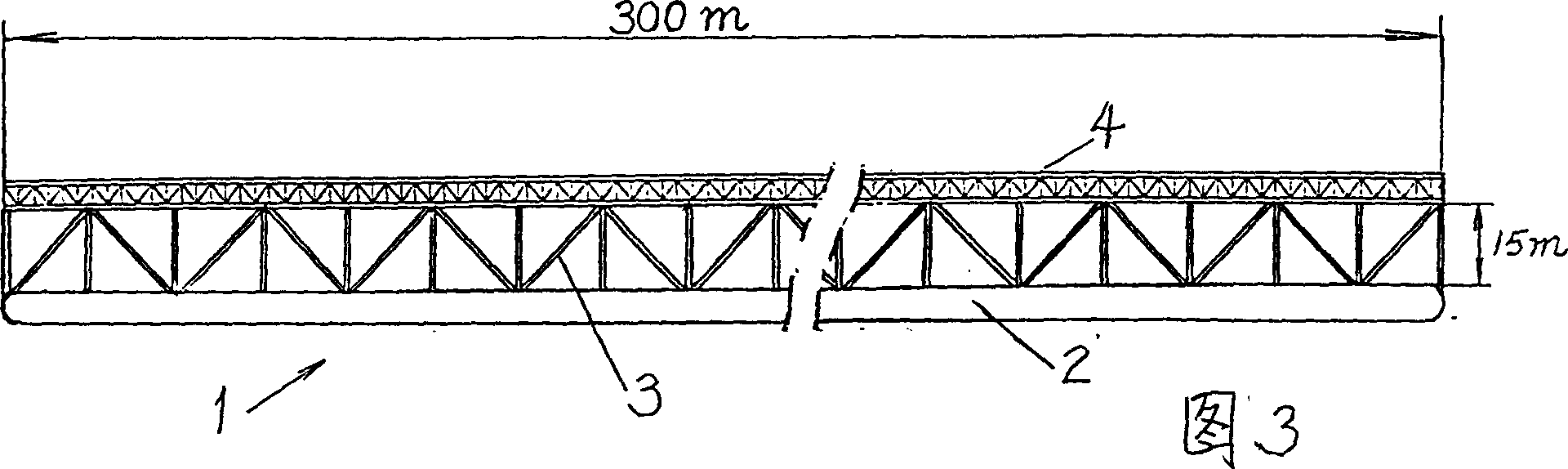

[0061] figure 1 , 2 and 3 represent a large-span truss type offshore floating platform 1, which is designed to be a floating airport at sea. The maximum wave height of the platform design extreme environment is 28 meters, that is, the width height is 14 meters. The operating environment is Class 6 sea state, and its upper limit wave height is about 6 meters.

[0062] The platform 1 has four floating bodies 2, connecting rods 3 and upper flight deck 4 arranged in parallel on the water surface. The floating body 2 is also a member of the truss at the same time. The platform deck is 300 meters long and 60 meters wide.

[0063] The floating body, the water working surface and the connecting rods are connected to each other to form an integral rigid truss structure, thus meeting the requirements of the aforementioned technical measure 1) in the technical solution of the present invention.

[0064] The following are the basic parameters of the platform structure.

[0065] The ...

example 2

[0088] Figure 8 Show that this example 2 platform has a square deck 4 ', side length 240 meters, has a large area flat deck, and the design purpose is a comprehensive base at sea, and has the ability to retract and release large-scale tethered balloons. The platform is designed for extreme environments with a maximum wave height of 28 meters. The working environment is 8 meters in wave height.

[0089] Cylindrical floating body 2' with a diameter of 3.2 meters, 16 vertically and horizontally, arranged orthogonally, at the intersection point p of the grid 1 ,p 2 Intersecting at all places, the vertical and horizontal grid spacing is 15 meters. The total volume of the floating body is about 59,000 cubic meters, the platform is fully loaded with a total weight of about 35,000 tons, and the height of the waterline is about 60% of the diameter of the floating body (1.85 meters). The distance from the lower edge of the platform deck structure to the upper edge of the floating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com