Method for preparing WC base hard alloy with high hardness and high toughness

A cemented carbide and high toughness technology, applied in the field of powder metallurgy materials, can solve problems that do not involve plate crystal WC grain crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

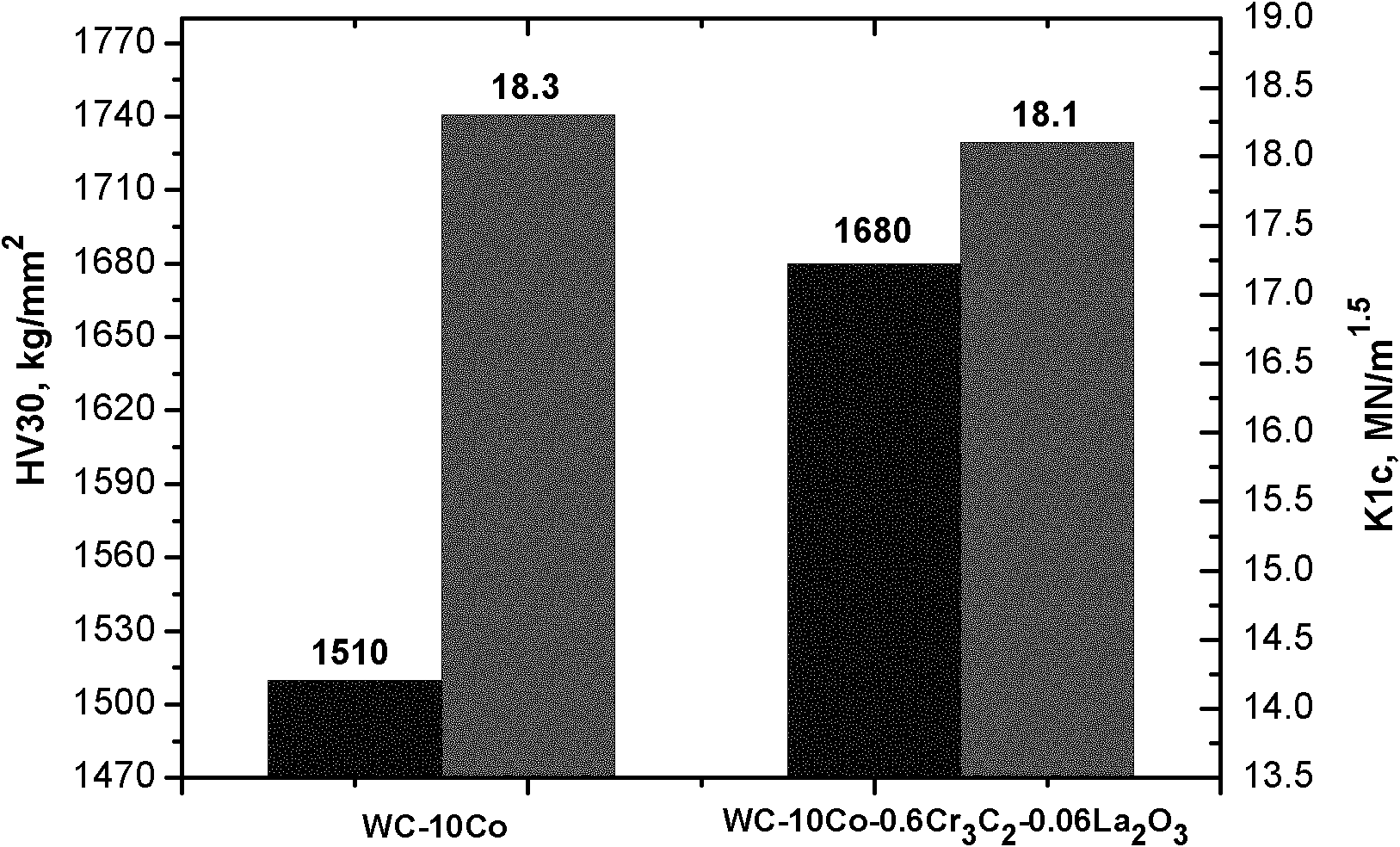

[0020] Use W powder with an average particle size of 46.4nm, graphite powder with an average particle size of 106.8nm, Co powder with an average particle size of 255.0nm, and Cr with a Fisher particle size of 1.45μm in the supply state (before 40h wet grinding pretreatment). 3 C 2 and anhydrous lanthanum nitrate as raw materials to prepare WC-10Co and WC-10Co-0.6Cr 3 C 2 -0.06La 2 o 3 Carbide. The alloy mixture was prepared by the traditional wet grinding process, the wet grinding time was 30h, and the ball-to-material ratio was 5:1. During the wet grinding process, paraffin wax accounting for 1.2% of the mixture mass fraction and PEG4000 accounting for 1.2% of the mixture mass fraction were added, A mixed solution of alcohol and n-hexane with a volume ratio of 1:1 was used as the wet grinding medium. The alloy samples were pressed by the traditional molding process, and the alloy samples were sintered by the traditional vacuum sintering process at 1380°C for 1 hour. The...

Embodiment 2

[0022] Using W powder with an average particle size of 46.4nm, graphite powder with an average particle size of 106.8nm, Ni powder with an average particle size of 205.0nm, and Cr with a Fisher particle size of 1.45μm in the supply state (before 40h wet grinding pretreatment). 3 C 2 And anhydrous yttrium nitrate as raw material to prepare WC-10Ni-0.8Cr 3 C 2 -0.04Y 2 o 3 Carbide. The alloy mixture was prepared by the traditional wet grinding process, the wet grinding time was 32h, and the ball-to-material ratio was 4:1. During the wet grinding process, paraffin wax accounting for 1.8% of the mixture mass fraction and PEG4000 accounting for 0.8% of the mixture mass fraction were added. A mixed solution of alcohol and n-hexane with a volume ratio of 1:1 was used as the wet grinding medium. The alloy samples were pressed by the traditional molding process, and the alloy samples were sintered by the pressure sintering process. The sintering temperature was 1370 ° C, the holdi...

Embodiment 3

[0024] Adopt the W powder of specific surface area average particle size 46.4nm, the graphite powder of specific surface area average particle size 106.8nm, the Co powder of specific surface area average particle size 255.0nm, the Ni powder of specific surface area average particle size 205.0nm, supply state (40h before wet grinding pretreatment ) Cr with a Fischer particle size of 1.45 μm 3 C 2 And anhydrous cerium chloride as raw material to prepare WC-3Ni-7Co-0.75Cr 3 C 2 -0.05CeO 2 Carbide. The alloy mixture was prepared by the traditional wet grinding process, the wet grinding time was 34h, the ball-to-material ratio was 4:1, 1.8% paraffin wax and 0.8% PEG4000 were added during the wet grinding process, A mixed solution of alcohol and n-hexane with a volume ratio of 1:1 was used as the wet grinding medium. The alloy samples were pressed by the traditional molding process, and the alloy samples were sintered by the pressure sintering process. The sintering temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fisherman's particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com