Temporary road pavement technology

A technology of temporary roads and crafts, applied in the direction of roads, roads, special pavements, etc., can solve the problems of increased repair and maintenance costs, easy dust, weak bonding strength, etc., to reduce maintenance costs, ensure strength and toughness, The effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

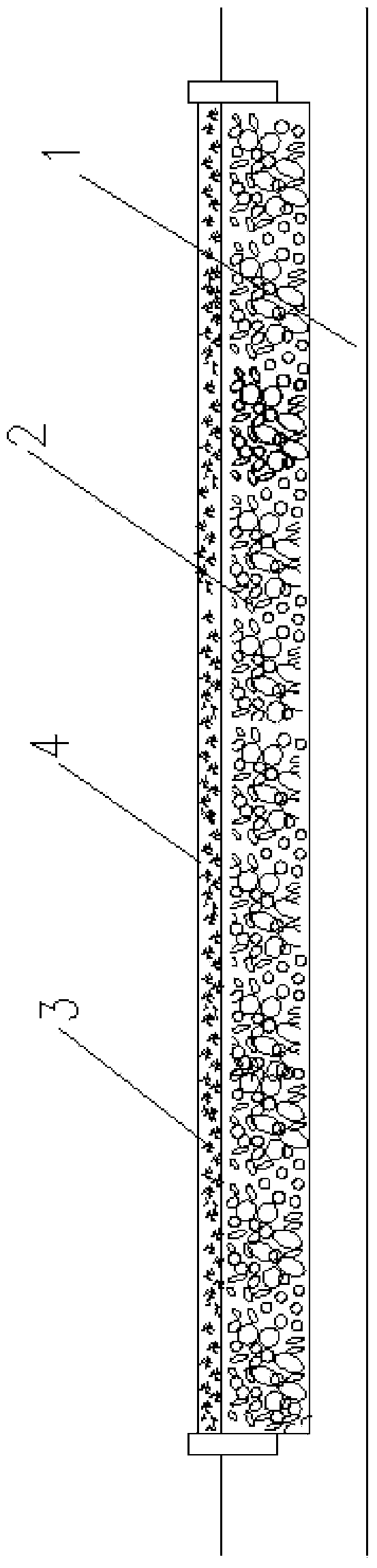

[0021] Such as figure 1 As shown, this embodiment provides a temporary road. The temporary road includes an original soil layer 1, a cushion layer 2, a surface layer 3, and a wear layer 4. The temporary road pavement adopts the following steps:

[0022] Step 1: Laying the cushion layer 2: According to the requirements of the specific road section, select crushed stones with a particle size of 150mm or less and uniform particles according to the laying thickness. The loose thickness is calculated as 1.2 times after compaction. The selected crushed stones are sieved and stacked separately according to different particle sizes. They must not be mixed to avoid distortion of the actual mix ratio, resulting in the filling effect that cannot meet the requirements of use. The sieved gravel shall not contain organic debris or garbage such as grass roots, leaves, plastics, etc.

[0023] The original soil is rolled to form a pavement, and then gravel is laid on the compacted pavement to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com