Anti-seepage method for mine underground reservoirs

A technology for underground reservoirs and mines, applied in mining equipment, earthwork drilling, water conservancy projects, etc., can solve problems affecting underground production safety, achieve the effects of enhancing safety and stability, improving project progress, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

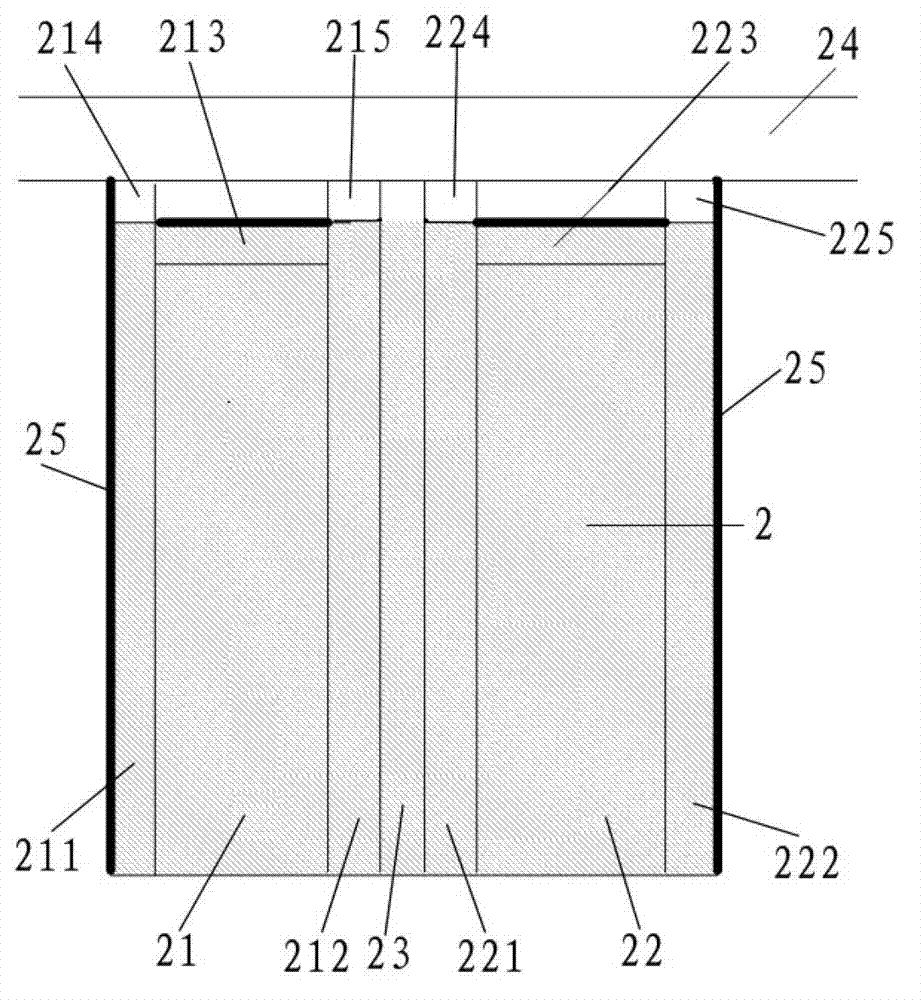

[0044] An underground reservoir in a mining area, such as figure 2 As shown in the shaded part 2, it includes two adjacent working surfaces 21, 22, and a coal pillar 23 is arranged between the working surfaces 21, 22. Since the working face 21 is mined earlier than the working face 22, in order to ensure the safety of the mine and protect groundwater resources, anti-seepage construction is carried out on the side of the left roadway 211 of the working face 21 at the same time as the roadway support. While the retraction channel 213 of the working face 21 is being excavated, anti-seepage construction is carried out on the side walls near the main road 24, and the roadways 211 and 212 are blocked after the mining of the working face 21 is completed (that is, in the figure 2 In the blank area 214,215 places to block the roadway).

[0045] When the roadway 222 on the right side of the working face 22 is excavated, anti-seepage construction is carried out on its side walls, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com