Long-span prestressed tension string beam and its construction method

A construction method and prestressing technology, applied in the direction of girders, joists, trusses, etc., can solve the problems of high risk of high-altitude operation, large one-time investment of tire frame, long installation period, etc., to achieve flexible assembly operations and reduce construction measures. The effect of investment, overall light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical means used by the present invention to achieve the purpose of the reservation invention, the following combined with the attached drawings and better embodiments, the specific implementation method of the Zhangxianliang structure construction method proposed by the invention is further explained in detail.

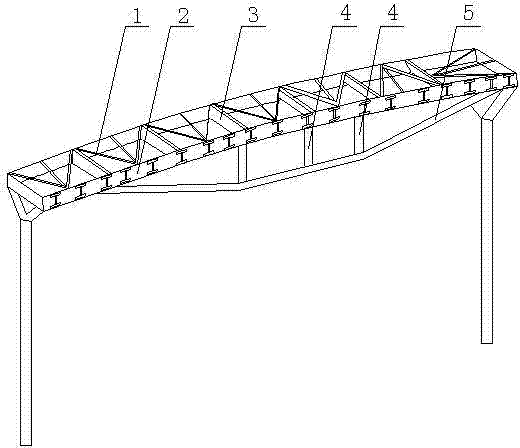

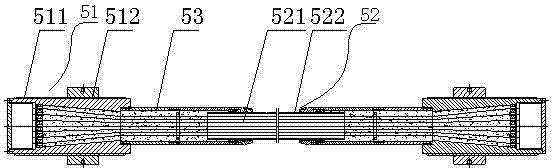

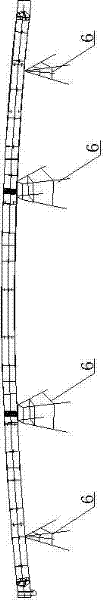

[0043] Reference figure 1 , A large span prestressed sine beam, including several unit beams assembled together, each unit beam includes two) long vertical beams 2. Several horizontal beams between the vertical beam 2 3. Several connects to the vertical directionLiangliang 2 and horizontal beam 3 of the beam 1. Several support rods 4, and pull cables 5, the upper end of the support rod 4 and the lower end of the horizontal beam 3 through the sales axis connection, the lower end of the support rod 4 is fixed with the pull cable.The two ends are fixed with the two ends of the unit beam. The pulp 5 and the unit beam form the trapez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com