Picking and placing device of test sorting machine

A technology for testing sorting machines and pick-and-place devices, which is applied in the direction of measuring devices, single semiconductor device testing, semiconductor/solid-state device testing/measurement, etc. It can solve problems such as complex composition, simplify composition, reduce manufacturing costs, and increase speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

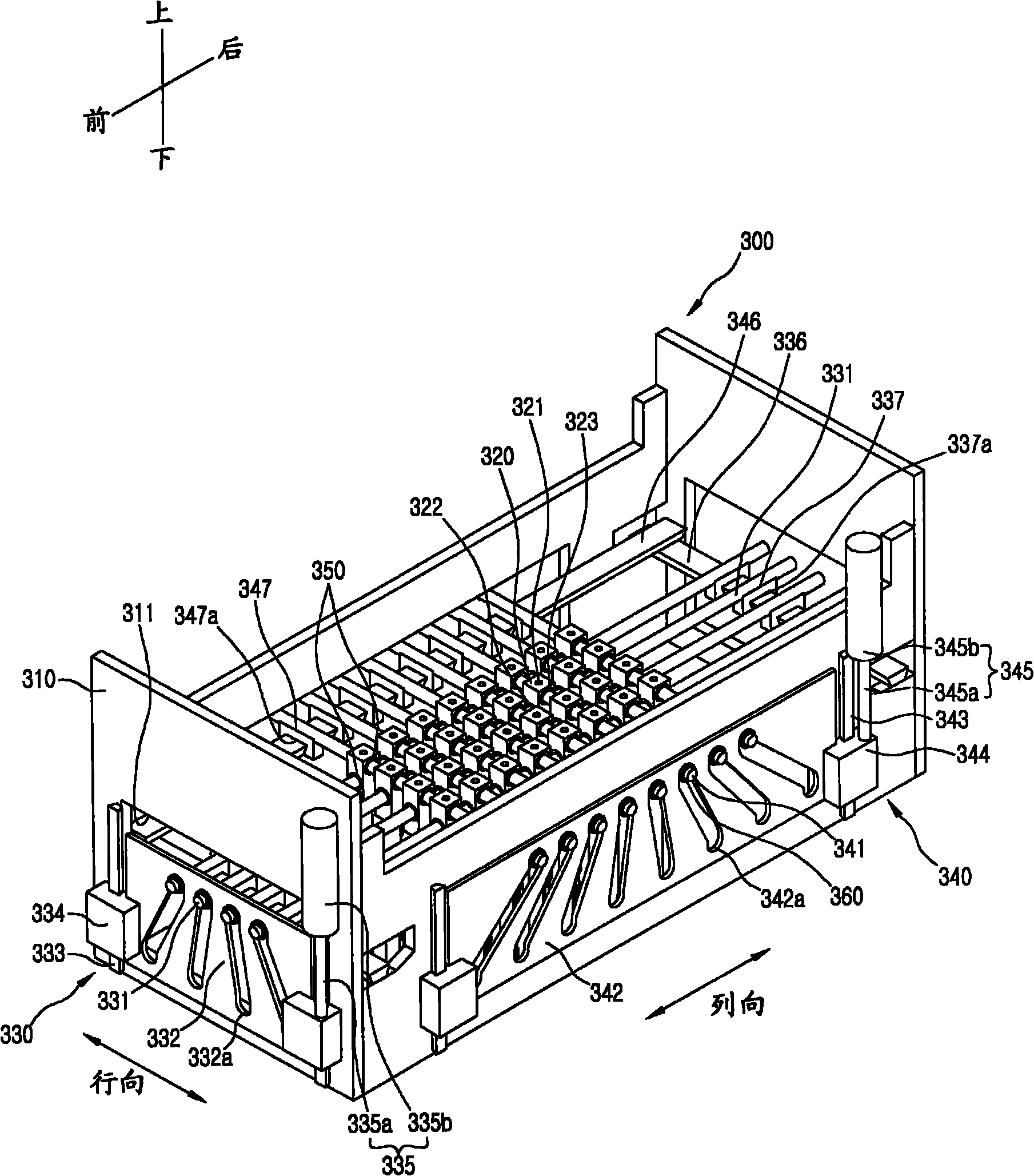

[0064] Hereinafter, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings, and repeated content or obvious matters will be omitted or briefly described. (Note: For the "row direction" and "column direction" mentioned in this article, please refer to image 3 , 4 , 8, 11, 12, 15, 16, 19, 22, 23, that is, "row direction" is the arrangement direction of rows, and "column direction" is the arrangement direction of columns)

[0065] image 3 is a perspective view of a pick-and-place device according to a first embodiment of the present invention, Figure 4 is an exploded perspective view showing the main configuration of the pick-and-place device according to the first embodiment of the present invention.

[0066] refer to image 3 and Figure 4 , The pick-and-place device 300 according to the embodiment of the present invention includes a housing 310 , a picker 320 , a row spacing adjusting device 330 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com