Continuous ion exchange technology for removing inorganic salt and adopted system

A continuous ion and inorganic salt technology, applied in the continuous ion exchange process and the system field adopted, can solve the problems of low utilization rate of ion exchange resin, large investment in equipment, large floor area, etc., to reduce equipment investment and streamline Process, the effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and specific embodiments.

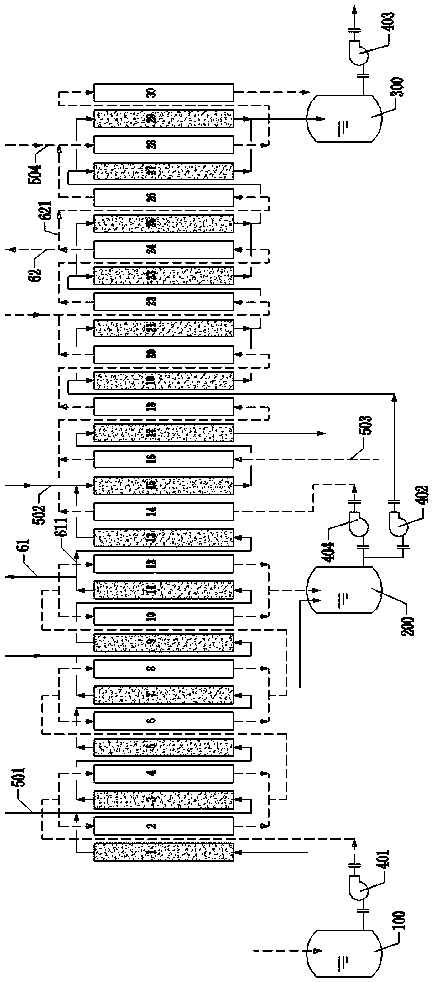

[0020] Such as figure 1 As shown, a continuous ion exchange process for removing inorganic salts includes the following steps:

[0021] 1) Cation adsorption: the raw material liquid enters the system in parallel from the two columns of No. 2 / 4 from the raw material tank 100 through the first transfer pump 401. After coming out of the 2 / 4, it enters in parallel to 6 / 8 for series adsorption, and 6 / 8 adsorption. After completion, enter 10-12 in parallel to perform three-stage adsorption to remove cations and enter the buffer tank 200. Before the three-stage adsorption, the material liquid in the buffer tank 200 is used to replace the rinse water in the No. 14 resin column by the fourth delivery pump 404, and the rinse water is returned to the third rinse pipe 503.

[0022] 2) After the cationic resin is saturated with adsorption, elution is performed to clean the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com