Microfluidic chip and manufacturing method thereof

A microfluidic chip and microfluidic technology, applied in chemical instruments and methods, instruments, laboratory utensils, etc., can solve problems such as complex structure, passive valve cannot be actively opened, closed or switched, and complex preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] According to the present invention, the preparation method of the microfluidic chip comprises:

[0051] (1) bonding the upper chip unit and the lower chip unit to each other, the surface of the upper chip unit and / or the lower chip unit includes a liquid storage hole, a fluid channel communicated with the liquid storage hole and a micro channel communicated with the fluid channel, The surface of the microchannel is formed with an arrayed three-dimensional micron and three-dimensional nanoscale structure, an arrayed three-dimensional microstructure, or an arrayed three-dimensional nanostructure, and the bonding method makes the microchannel closed on the upper chip Between the unit and the lower chip unit;

[0052] The preparation method of the upper chip unit and / or the lower chip unit includes forming a liquid storage hole, a fluid channel and a microchannel on the surface of the substrate of the upper chip unit and / or the lower chip unit, so that the liquid storage ho...

Embodiment 1

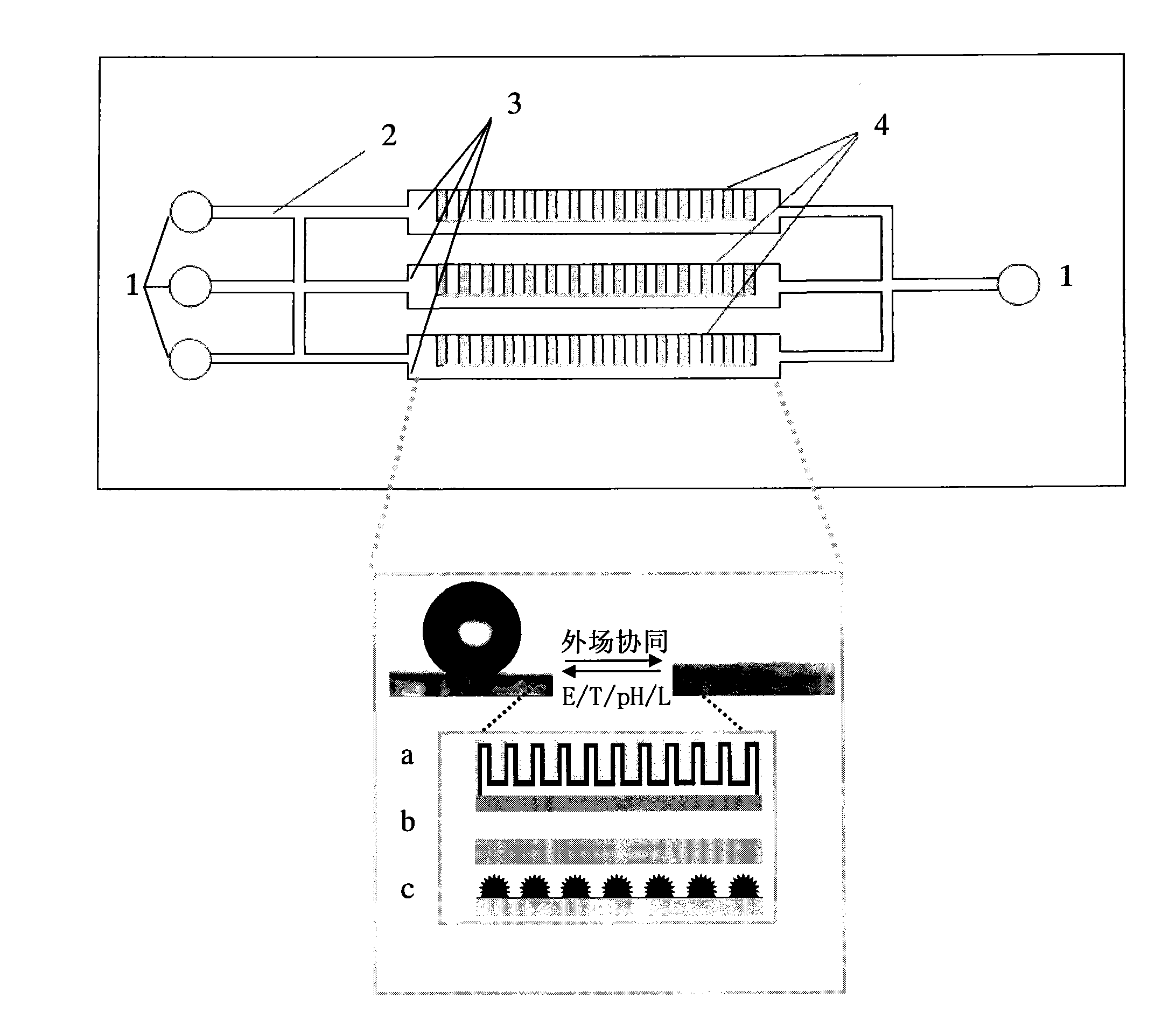

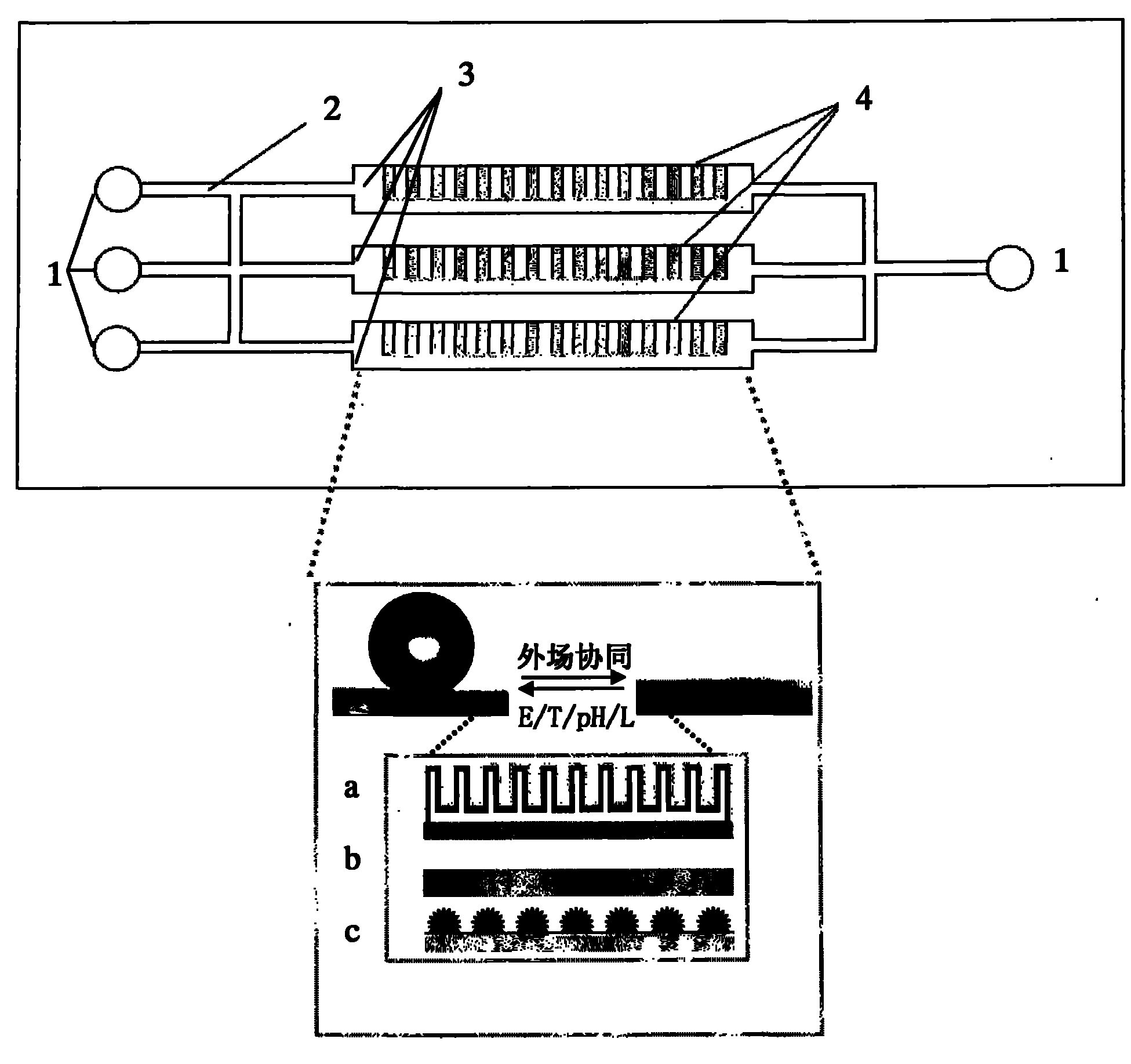

[0066] This example is used to illustrate the preparation of microfluidic chip

[0067] Such as figure 1 As shown, the design graph of the microfluidic chip is drawn by computer-aided design (CAD), and according to the design drawing, laser etching is used to engrave the surface of a quartz plate (4 cm in length, 3 cm in width, and 1 mm in thickness). Etch out the required chip reservoir hole 1 (round hole with a diameter of 1 mm), fluid channel 2 (20×0.3×0.3 mm (length / width / depth)) and microchannel 3 (15×0.2×0.2 mm ( length / width / depth)). Wash the quartz plate successively with deionized water, ethanol, acetone, and deionized water, and dry it at 100°C.

[0068] Zinc oxide (ZnO) nanowire arrays are prepared on the surface of microchannels by a two-step solution method: ZnO sol is evenly coated on the quartz surface with microchannels, and annealed at 420 ° C to form a layer of 100-200 nm thick seed crystals The membrane was then immersed in an aqueous solution of zinc nit...

Embodiment 2

[0072] This example is used to illustrate the preparation of microfluidic chip

[0073] Such as figure 1As shown, the design graphics of the microfluidic chip are drawn by computer-aided design (CAD). According to the design drawing, an excimer laser etching machine is used to carve the surface of a piece of quartz (5 cm in length, 4 cm in width, and 2 mm in thickness). Etch out the required chip reservoir holes (circular holes with a diameter of 2 mm), fluid channels (20×0.2×0.2 mm (length / width / depth)) and microchannels (15×0.2×0.2 mm (length / width / depth)), clean the substrate surface with deionized water, ethanol, deionized water, ethanol, and let it dry naturally.

[0074] Through a two-step method: soft etching and chemical etching, papillary cone array micro and nano hierarchical structures are prepared in the microchannel, the simple steps are as follows: use a photomask prepared by a chromium layer, expose it through a photolithography machine, Transfer the pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com