Control of operation conditions within fluidic systems

a fluidic system and operation condition technology, applied in the direction of fluid speed measurement, electrolysis, isotope separation, etc., can solve the problems of inability to readily access and control the reaction, and inability to control the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. General

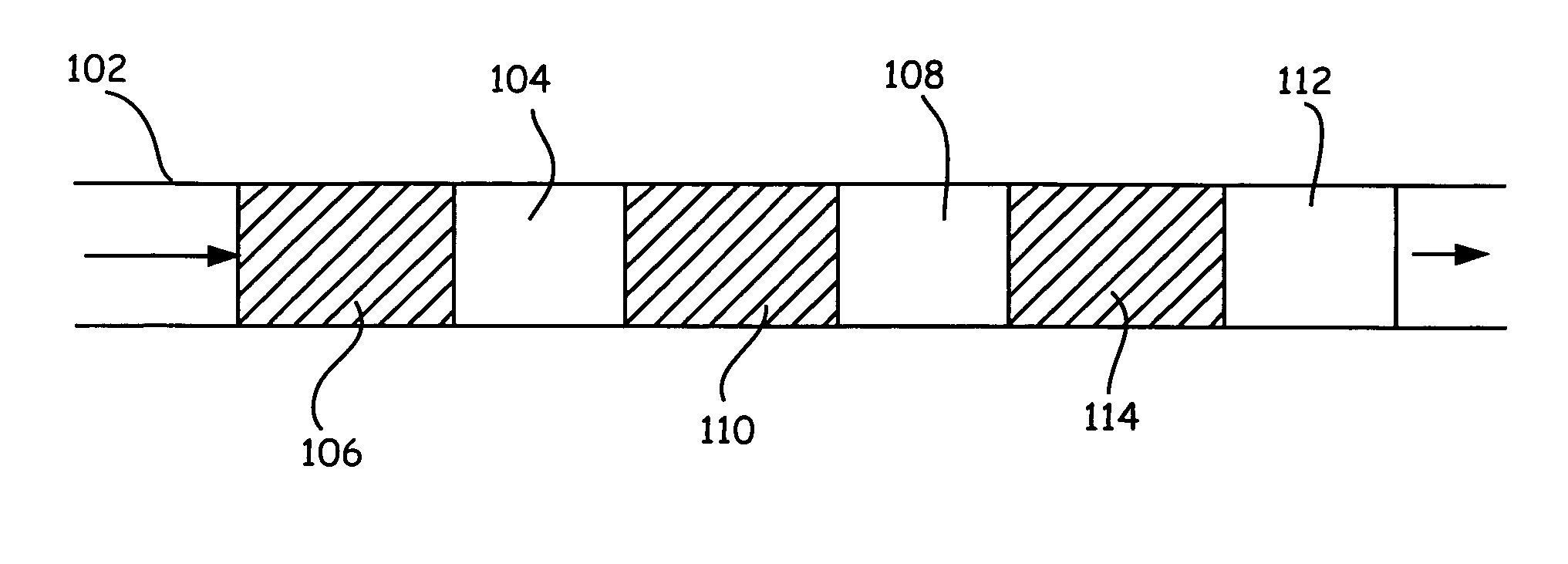

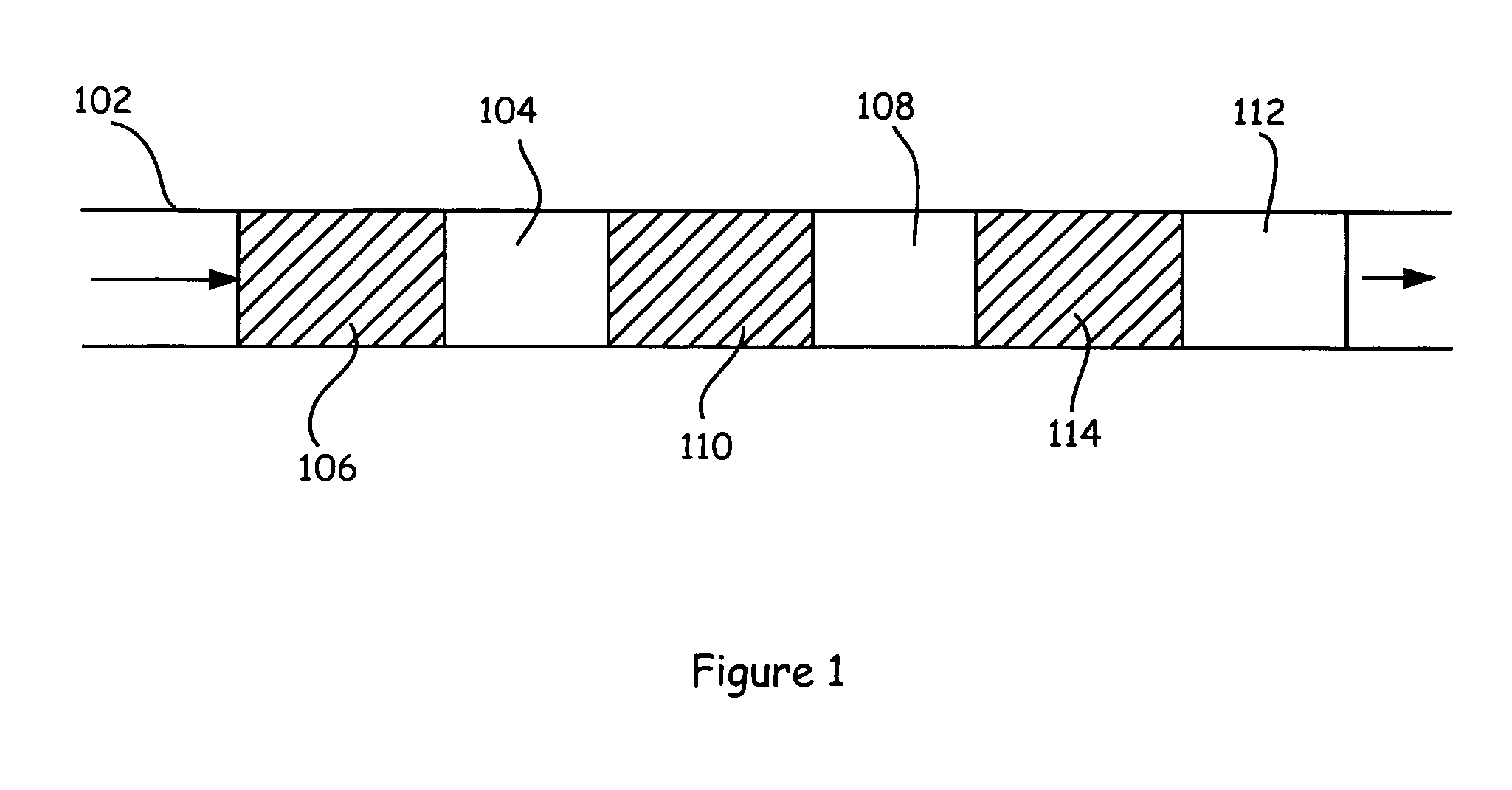

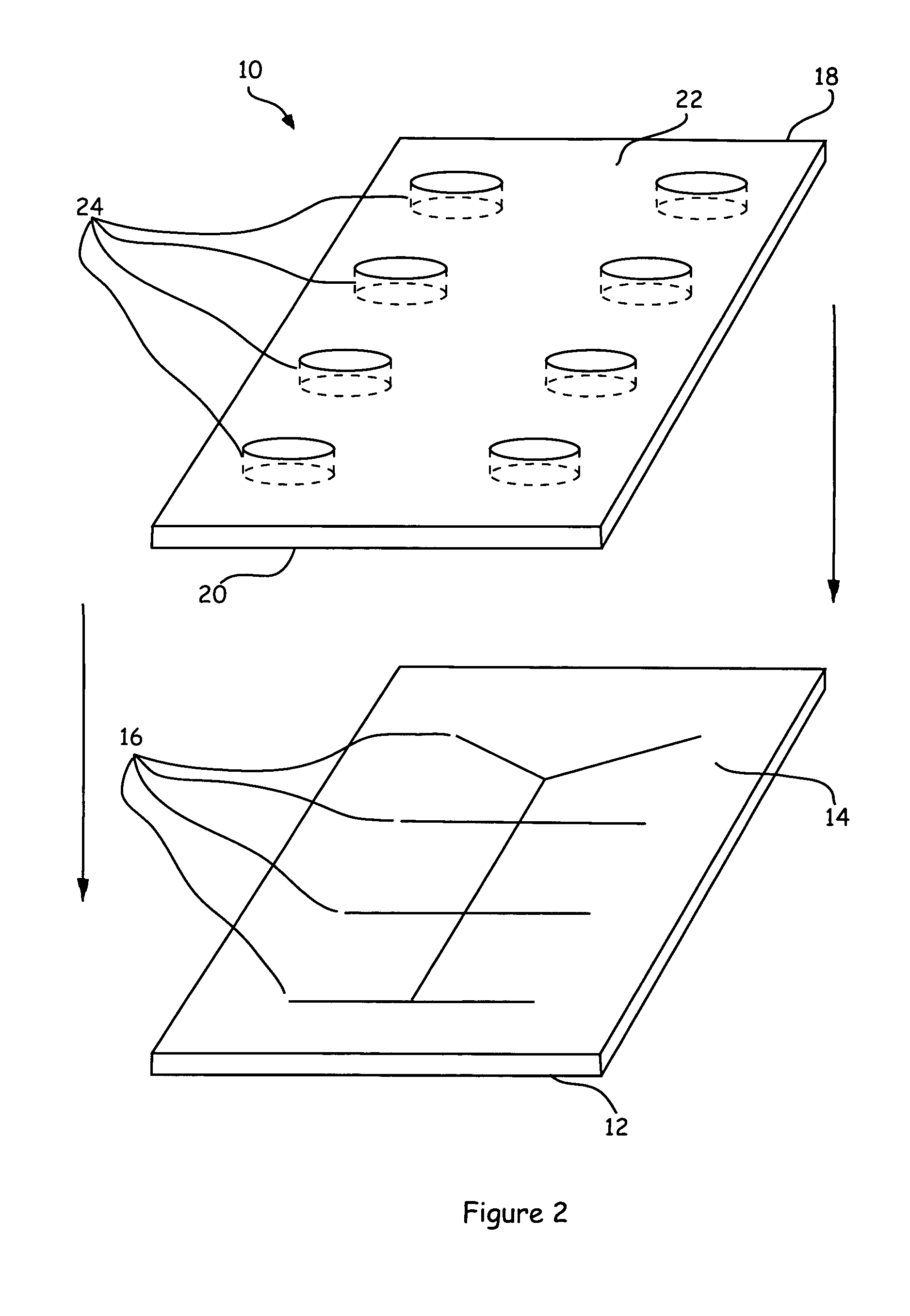

[0011] The present invention generally provides methods for optimizing the operation of microscale channel based systems through the use of environmental or operation control reagents within the fluids that are being transported through the capillary channels. In optionally preferred aspects of the invention, the environmental or operation control reagents are transported in fluid regions that are different from fluid regions that contain the reagents of interest for a given analysis, although such reagents may optionally be disposed within the fluid regions that contain the reagents of interest.

[0012] As used herein, the phrase “environmental control reagent” or “operation control reagent” refers to a reagent that typically is not involved directly in the reaction of interest, but instead modifies, controls or provides an indication of the state of the environment within a microscale channel in which a reaction of interest is taking place, so as to control that environme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com