Microfluidic cell array chip for high-throughput medicament screening, method and use

A cell array and microfluidic technology, applied in the direction of supporting/immobilizing microorganisms, biochemical equipment and methods, specific-purpose bioreactors/fermenters, etc., to achieve low reagent consumption and solve the effect of disordered cell distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

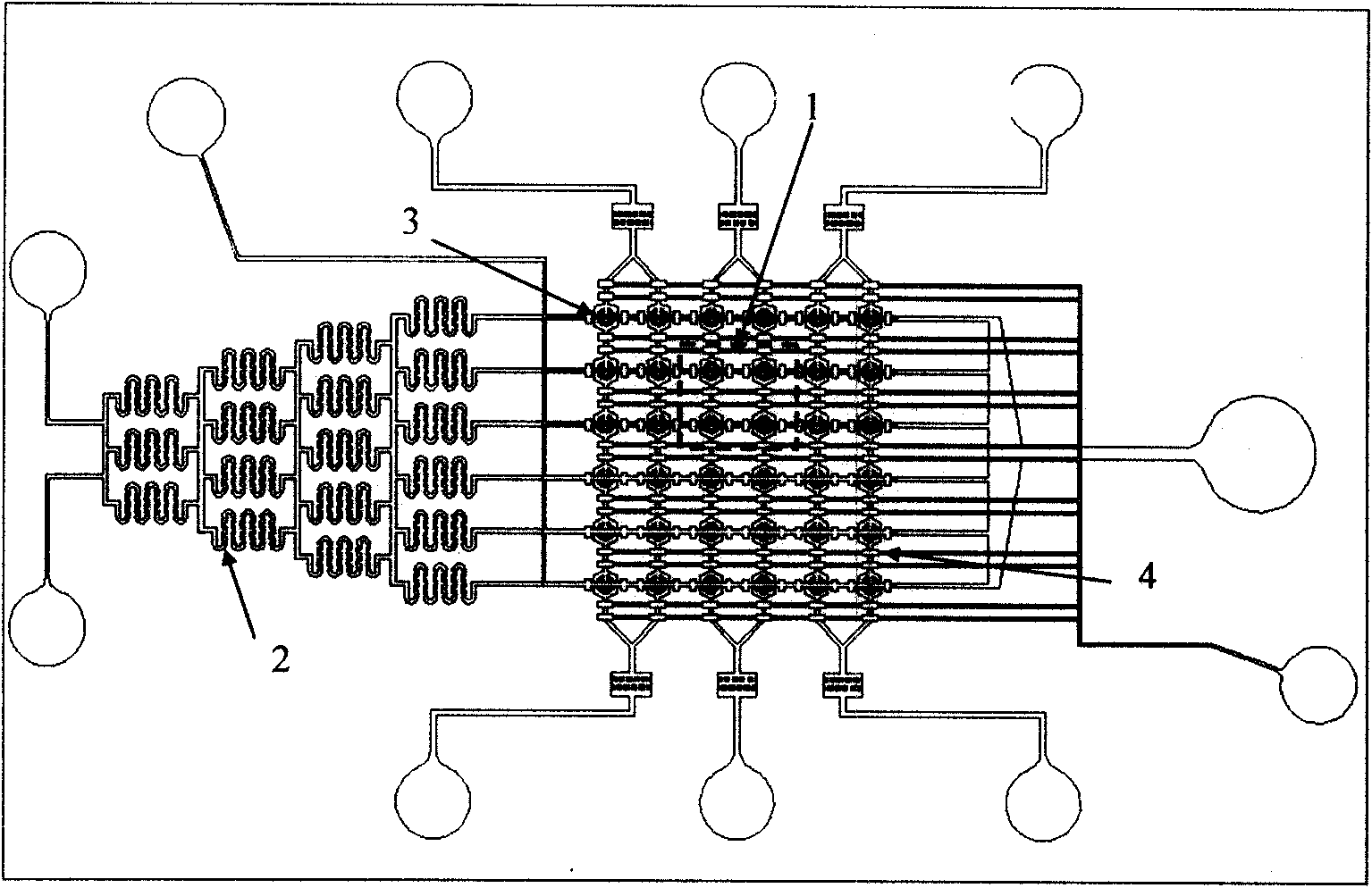

[0032] Embodiment 1, the preparation of chip

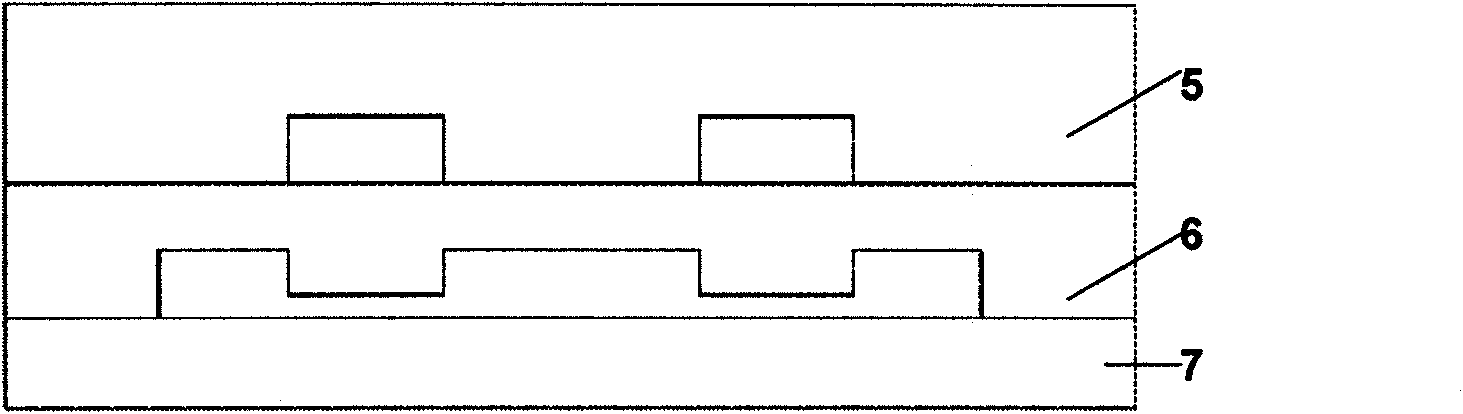

[0033] The microfluidic chip is manufactured by multiple times of soft photolithography and molding. The chip adopts polydimethylsiloxane (PDMS) material with good light transmission, gas permeability and biocompatibility, which is bonded with conventional glass slides to form a cell culture pool array and its microchannel network structure. The key process of chip making is to make a double-layer PDMS (polydimethylsiloxane) chip by making a fluid channel layer mold of double-layer SU-8 negative photoresist to form a dam structure and thermal bonding. Specific steps are as follows:

[0034] 1) On the cleaned silicon substrate, spin-coat diluted SU8-2005 (MicroChemCorp, MA, USA, diluted with SU8-2025 and cyclopentanone at a volume ratio of 100:53), with a thickness of about 5 μm, Put it on a hot plate and bake at 65°C for 1 minute, then raise the temperature to 95°C and keep it for 2 minutes, then slowly cool down to room tempera...

Embodiment 2

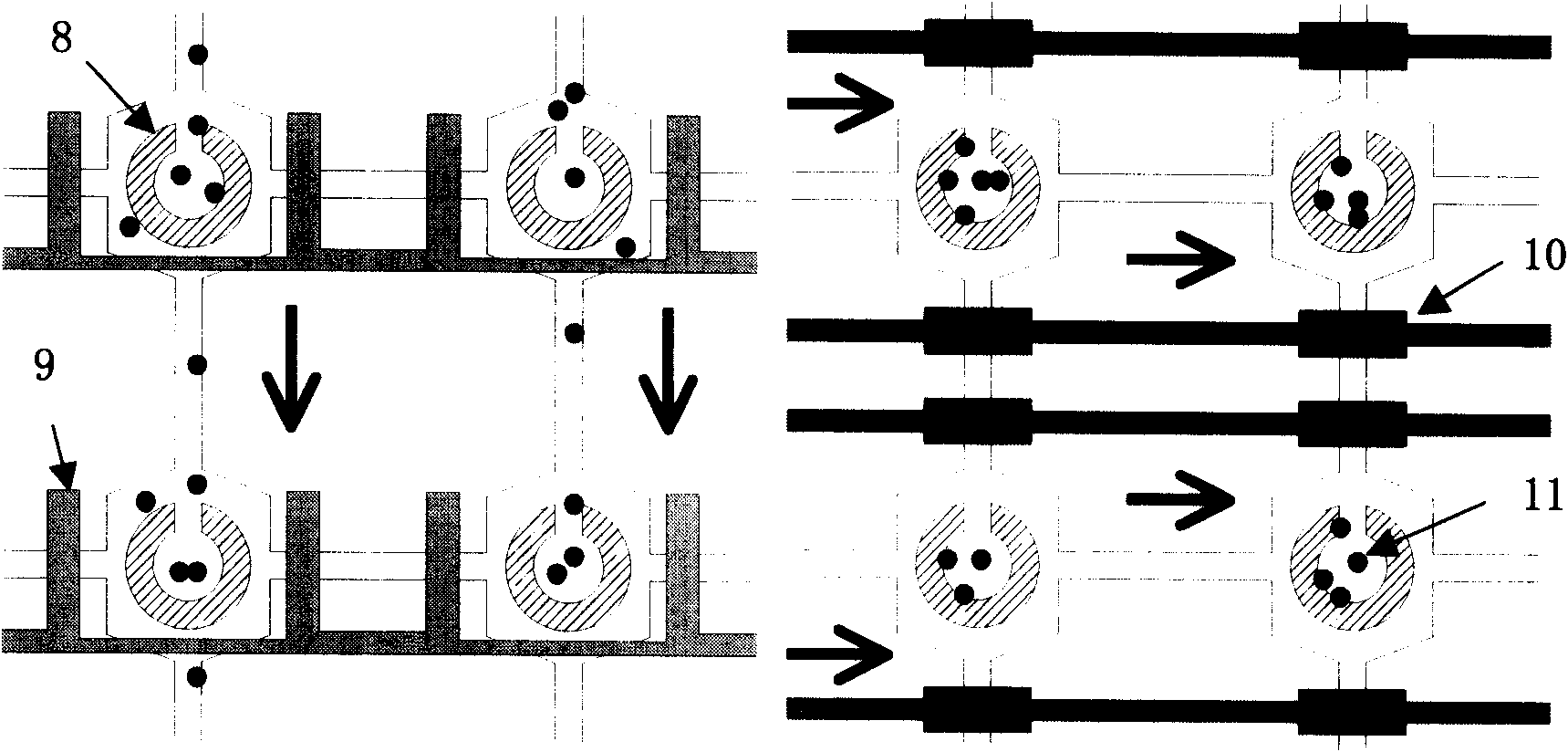

[0039] Embodiment 2, the application of chip

[0040] The cells cultured on the chip were human liver cancer cells SMMC-7721, normal human liver cells HL-7702 and umbilical vein endothelial cells. The cell culture medium is RMPI1640 (Gibco), adding 10% fetal bovine serum (Hangzhou Sijiqing) and 1% streptocyanine double antibody (Hangzhou Jinuo Biomedical Technology Co., Ltd.), and the cell digestion solution is 0.25% trypsin and 0.02% EDTA (Hangzhou Jinuo Biomedical Technology Co., Ltd.).

[0041] The chip was irradiated with 75% ethanol and irradiated with ultraviolet light for 1 hour for disinfection. First, use a syringe pump to pass through the cell culture solution into the chip for 2 hours to eliminate the residual ethanol and air bubbles in the chip, which is conducive to the adherent growth of cells in the culture chamber. The three types of cells are respectively introduced into each columnar cell culture chamber of the chip through a syringe pump for cell culture. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com