Method for preparing high-purity anhydrous scandium acetate and high-purity scandium oxide

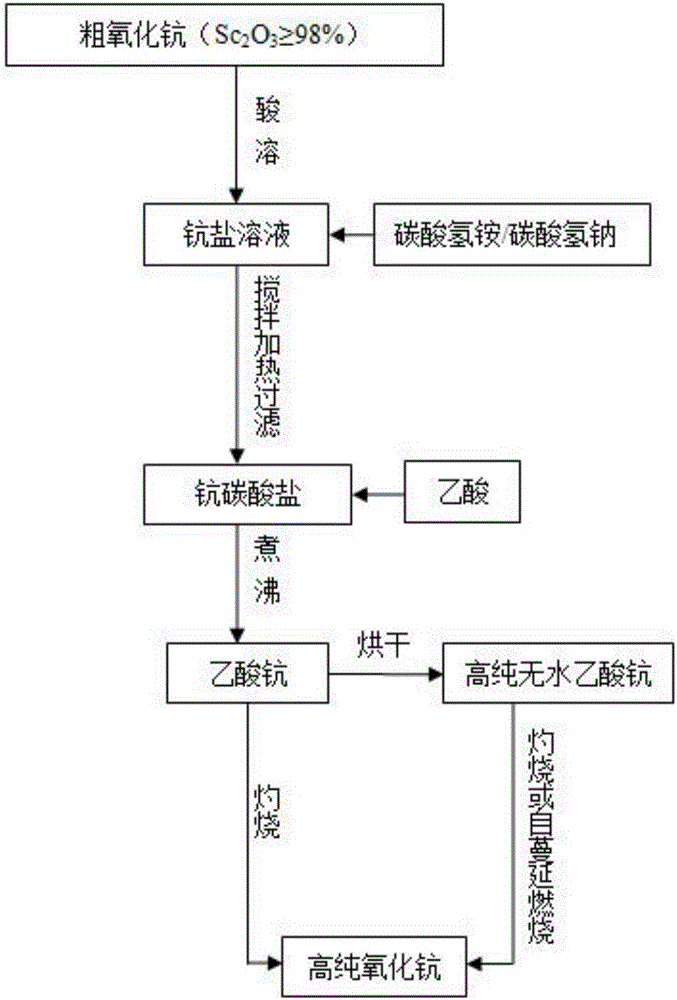

A technology of scandium oxide and scandium acetate is applied in the preparation of organic compounds, the preparation of carboxylate, the preparation of carboxylate, etc., and can solve the problems of a large amount of encapsulated moisture or other impurities, unsuitable for industrial production, and a large amount of acidic wastewater, To achieve the effect of fast filtration, loose structure and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 100g of crude scandium oxide raw material (relative rare earth purity 99.91%, non-rare earth impurities 1.2%), add 6mol / L hydrochloric acid 260ml, heat to 80°C to dissolve, filter to obtain filtrate I; under stirring condition, keep the temperature at 30°C, Add ammonium bicarbonate to the filtrate I, and when the pH is 6.5, stop adding ammonium bicarbonate, wash the precipitate twice with pure water, and filter; add 4 mol / L acetic acid to the precipitate according to 1 times the theoretical amount, stir to dissolve, and 25°C, after the reaction, filter, collect the filtrate II, stir and heat the filtrate II to 100°C, scandium acetate crystals precipitate, add glacial acetic acid, control the concentration of acetic acid in the solution to 1mol / L, keep the temperature at 100°C for 5min, and keep it hot Filtrate, wash the scandium acetate crystals twice with absolute ethanol; dry the crystals at 100°C to obtain high-purity anhydrous scandium acetate, and burn high-pur...

Embodiment 2

[0024] Take 100g of crude scandium oxide raw material (relative rare earth purity 99.5%, non-rare earth impurities 1.5%), add 6mol / L nitric acid 260ml, heat to 90°C to dissolve, filter to obtain filtrate I; under stirring conditions, keep the temperature at 50°C, Add ammonium bicarbonate to the filtrate I. When the pH is 7.5, stop adding ammonium bicarbonate, wash the precipitate three times with pure water, and filter; add 6 mol / L acetic acid to the precipitate according to 1.2 times the theoretical amount, stir to dissolve, and the temperature is 20°C. After the reaction, filter and collect the filtrate Ⅱ, stir and heat the filtrate Ⅱ to 95°C, scandium acetate crystals are precipitated, then add glacial acetic acid to the solution, control the concentration of acetic acid in the solution to 2mol / L, keep the temperature for 10min, filter while hot, and use for precipitation Wash with absolute ethanol three times, bake scandium acetate at 80°C for 2 hours to obtain scandium ace...

Embodiment 3

[0026] Take 100g of crude scandium oxide raw material (relative rare earth purity 99.95%, non-rare earth impurities 0.92%), add 5mol / L hydrochloric acid 260ml, heat to 100°C to dissolve, filter to obtain filtrate I; under stirring conditions, keep the temperature at 40°C, Add sodium bicarbonate to the filtrate I. When the pH is 7.0, stop adding sodium bicarbonate, wash the precipitate with water three times, and filter; add 5 mol / L acetic acid to the precipitate according to 1.5 times the theoretical amount, stir and dissolve, and the temperature is 45 ° C. After the reaction, Filtrate, collect filtrate II, stir and heat filtrate II to 90°C, scandium acetate crystals precipitate, add glacial acetic acid to the solution, control the solubility of acetic acid to 4mol / L, keep the temperature for 15min, filter while hot, and wash the precipitate with absolute ethanol Second, scandium acetate was burned at 550°C for 2 hours to obtain high-purity scandium oxide (relative rare earth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com