Method for purifying ursodeoxycholic acid

A technology of ursodeoxycholic acid and a purification method, which is applied in the field of purification of ursodeoxycholic acid, can solve the problems of high energy consumption, prolonged production cycle, and many steps, and achieve good selectivity, low reagent consumption, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

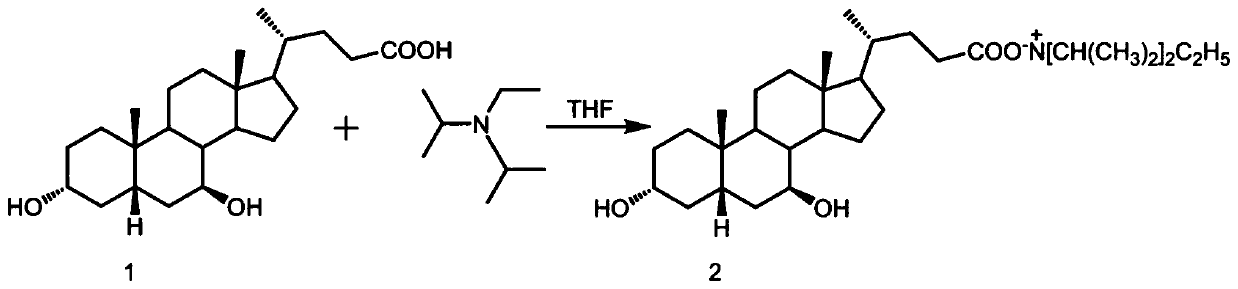

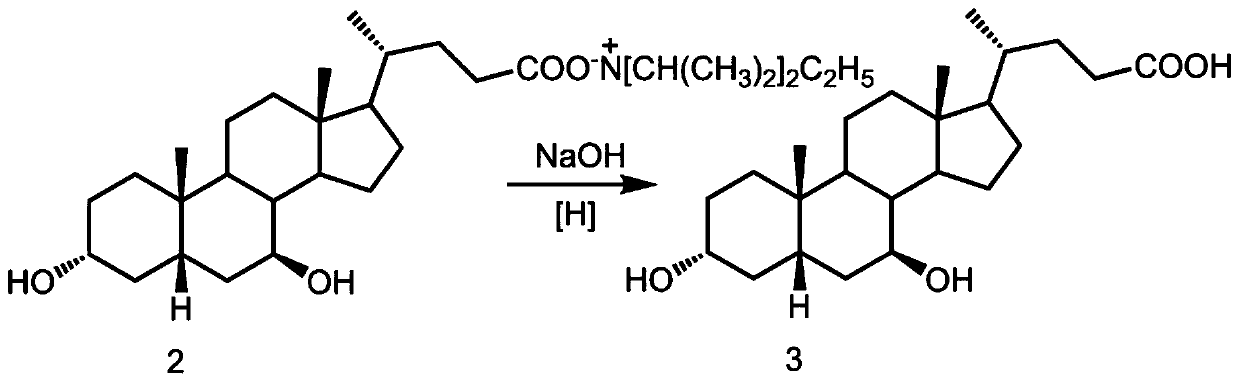

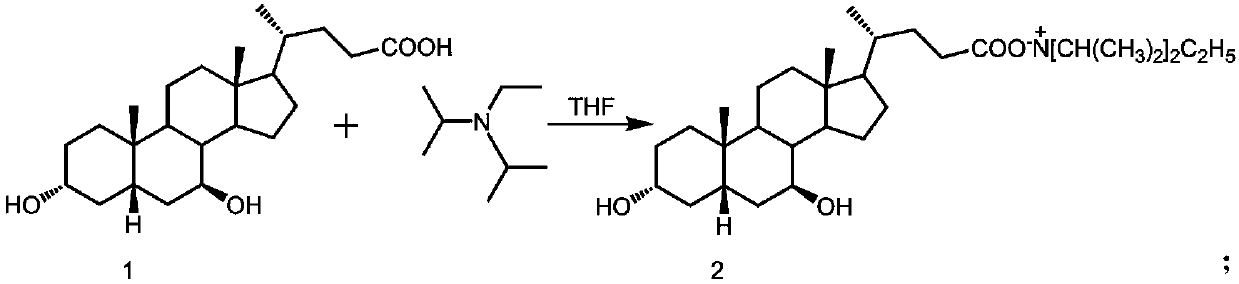

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 10 g of crude ursodeoxycholic acid containing 95% in 100 mL of tetrahydrofuran, stir and heat up to 55 ° C, add 3.29 g of diisopropylethylamine, and react at 65 ° C for 1 hour, then cool the resulting slurry to 0-5°C, suction filter the crystals, rinse the filter cake with an appropriate amount of tetrahydrofuran, and dry under reduced pressure at 55-60°C to obtain 13 g of ursodeoxycholic acid diisopropylethylammonium salt.

[0025] Suspend the above diisopropylethylammonium ursodeoxycholic acid in 260mL of ultrapure water, add 20% aqueous sodium hydroxide solution, adjust the pH to 12.0 at 25-30°C; then extract the solution with dichloromethane Finally, put it into the reaction bottle, stir and heat up to 45°C, add 5% dilute hydrochloric acid dropwise to adjust the pH to 2.0, cool the slurry to 20°C, crystallize, filter with suction, rinse the residual acid solution with ultrapure water, collect and dry, and obtain Pure ursodeoxycholic acid 9.2g.

Embodiment 2

[0027] Dissolve 10 g of crude ursodeoxycholic acid containing 85% in 100 mL of tetrahydrofuran, stir and heat up to 60 °C, add 3.25 g of diisopropylethylamine, and react at 65 °C for 40 min, then cool the resulting slurry to 0 -5°C, the crystals were suction-filtered, the filter cake was washed with an appropriate amount of tetrahydrofuran, and dried under reduced pressure at 55-60°C to obtain 12.5 g of ursodeoxycholic acid diisopropylethylammonium salt.

[0028] Suspend the above diisopropylethylammonium ursodeoxycholic acid in 250mL ultrapure water, add 20% aqueous sodium hydroxide solution, adjust the pH to 12.2 at 25-30°C; then extract the solution with dichloromethane Finally, put it into the reaction bottle, stir and heat up to 48°C, add 5% dilute hydrochloric acid dropwise to adjust the pH to 2.4, cool the slurry to 25°C, crystallize, filter with suction, rinse the residual acid solution with ultrapure water, collect and dry, and get Pure ursodeoxycholic acid 8.9g.

Embodiment 3

[0030] Dissolve 10 g of crude ursodeoxycholic acid containing 80% in 100 mL of tetrahydrofuran, stir and heat up to 50 ° C, add 3.3 g of diisopropylethylamine, and react at 65 ° C for 1.5 hours, then cool the resulting slurry to 0-5°C, suction filter the crystals, rinse the filter cake with an appropriate amount of tetrahydrofuran, and dry under reduced pressure at 55-60°C to obtain 13.2 g of ursodeoxycholic acid diisopropylethylammonium salt.

[0031] Suspend the above diisopropylethylammonium ursodeoxycholic acid in 250mL ultrapure water, add 20% aqueous sodium hydroxide solution, adjust the pH to 12.5 at 25-30°C; then extract the solution with dichloromethane Finally, put it into the reaction bottle, stir and heat up to 50°C, add 5% dilute hydrochloric acid dropwise to adjust the pH to 2.5, cool the slurry to 22°C, crystallize, filter with suction, rinse the residual acid solution with ultrapure water, collect and dry, and obtain Pure ursodeoxycholic acid 8.7g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com