A kind of preparation method of high-purity anhydrous scandium acetate and high-purity scandium oxide

A technology of scandium acetate and scandium oxide, which is applied in the preparation of organic compounds, carboxylate salts, carboxylate salts, etc. It can solve the problems of wrapping water or other impurities, unsuitable for industrial production, and large amount of acidic wastewater. Achieve the effect of fast filtration speed, loose structure and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

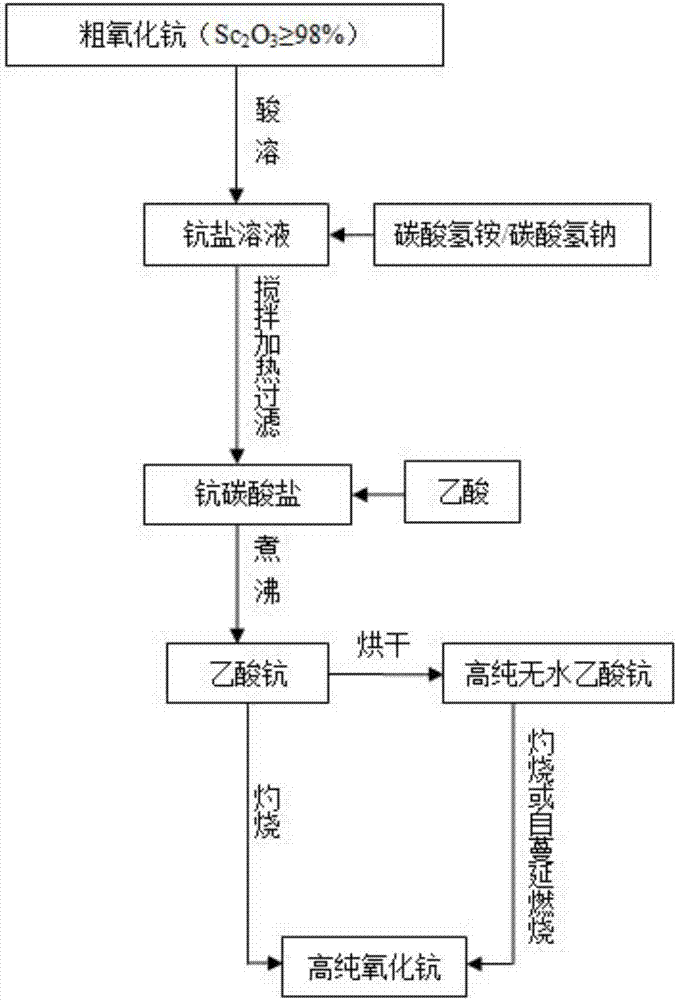

Method used

Image

Examples

Embodiment 1

[0022] Take 100g of crude scandium oxide raw material (relative rare earth purity 99.91%, non-rare earth impurities 1.2%), add 6mol / L hydrochloric acid 260ml, heat to 80°C to dissolve, filter to obtain filtrate I; under stirring condition, keep the temperature at 30°C, Add ammonium bicarbonate to the filtrate I, and when the pH is 6.5, stop adding ammonium bicarbonate, wash the precipitate twice with pure water, and filter; add 4 mol / L acetic acid to the precipitate according to 1 times the theoretical amount, stir to dissolve, and 25°C, after the reaction, filter, collect the filtrate II, stir and heat the filtrate II to 100°C, scandium acetate crystals precipitate, add glacial acetic acid, control the concentration of acetic acid in the solution to 1mol / L, keep the temperature at 100°C for 5min, and keep it hot Filtrate, wash the scandium acetate crystals twice with absolute ethanol; dry the crystals at 100°C to obtain high-purity anhydrous scandium acetate, and burn high-pur...

Embodiment 2

[0024] Take 100g of crude scandium oxide raw material (relative rare earth purity 99.5%, non-rare earth impurities 1.5%), add 6mol / L nitric acid 260ml, heat to 90°C to dissolve, filter to obtain filtrate I; under stirring conditions, keep the temperature at 50°C, Add ammonium bicarbonate to the filtrate I. When the pH is 7.5, stop adding ammonium bicarbonate, wash the precipitate three times with pure water, and filter; add 6 mol / L acetic acid to the precipitate according to 1.2 times the theoretical amount, stir to dissolve, and the temperature is 20°C. After the reaction, filter and collect the filtrate Ⅱ, stir and heat the filtrate Ⅱ to 95°C, scandium acetate crystals are precipitated, then add glacial acetic acid to the solution, control the concentration of acetic acid in the solution to 2mol / L, keep the temperature for 10min, filter while hot, and use for precipitation Wash with absolute ethanol three times, bake scandium acetate at 80°C for 2 hours to obtain scandium ace...

Embodiment 3

[0026] Take 100g of crude scandium oxide raw material (relative rare earth purity 99.95%, non-rare earth impurities 0.92%), add 5mol / L hydrochloric acid 260ml, heat to 100°C to dissolve, filter to obtain filtrate I; under stirring conditions, keep the temperature at 40°C, Add sodium bicarbonate to the filtrate I. When the pH is 7.0, stop adding sodium bicarbonate, wash the precipitate with water three times, and filter; add 5 mol / L acetic acid to the precipitate according to 1.5 times the theoretical amount, stir and dissolve, and the temperature is 45 ° C. After the reaction, Filtrate, collect filtrate II, stir and heat filtrate II to 90°C, scandium acetate crystals precipitate, add glacial acetic acid to the solution, control the solubility of acetic acid to 4mol / L, keep the temperature for 15min, filter while hot, and wash the precipitate with absolute ethanol Second, scandium acetate was burned at 550°C for 2 hours to obtain high-purity scandium oxide (relative rare earth p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com