Liquid homogenizing device for printed circuit board

A printed circuit board and printed circuit technology, which is applied in the fields of printed circuit liquid treatment, printed circuit, printed circuit manufacturing, etc., can solve problems such as unevenness, pool effect treatment effect, etc., to prevent excessive treatment, avoid pool effect, and avoid treatment uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

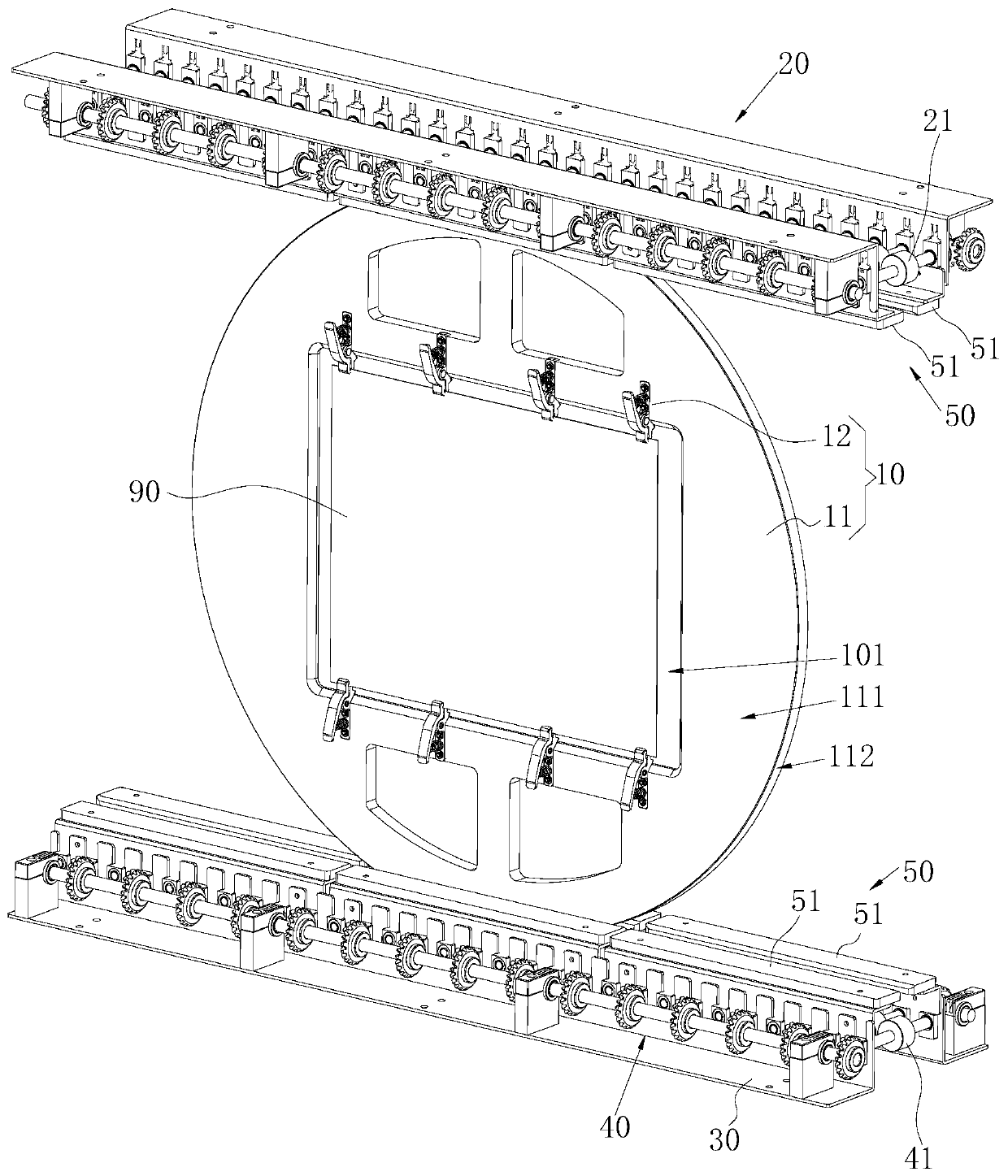

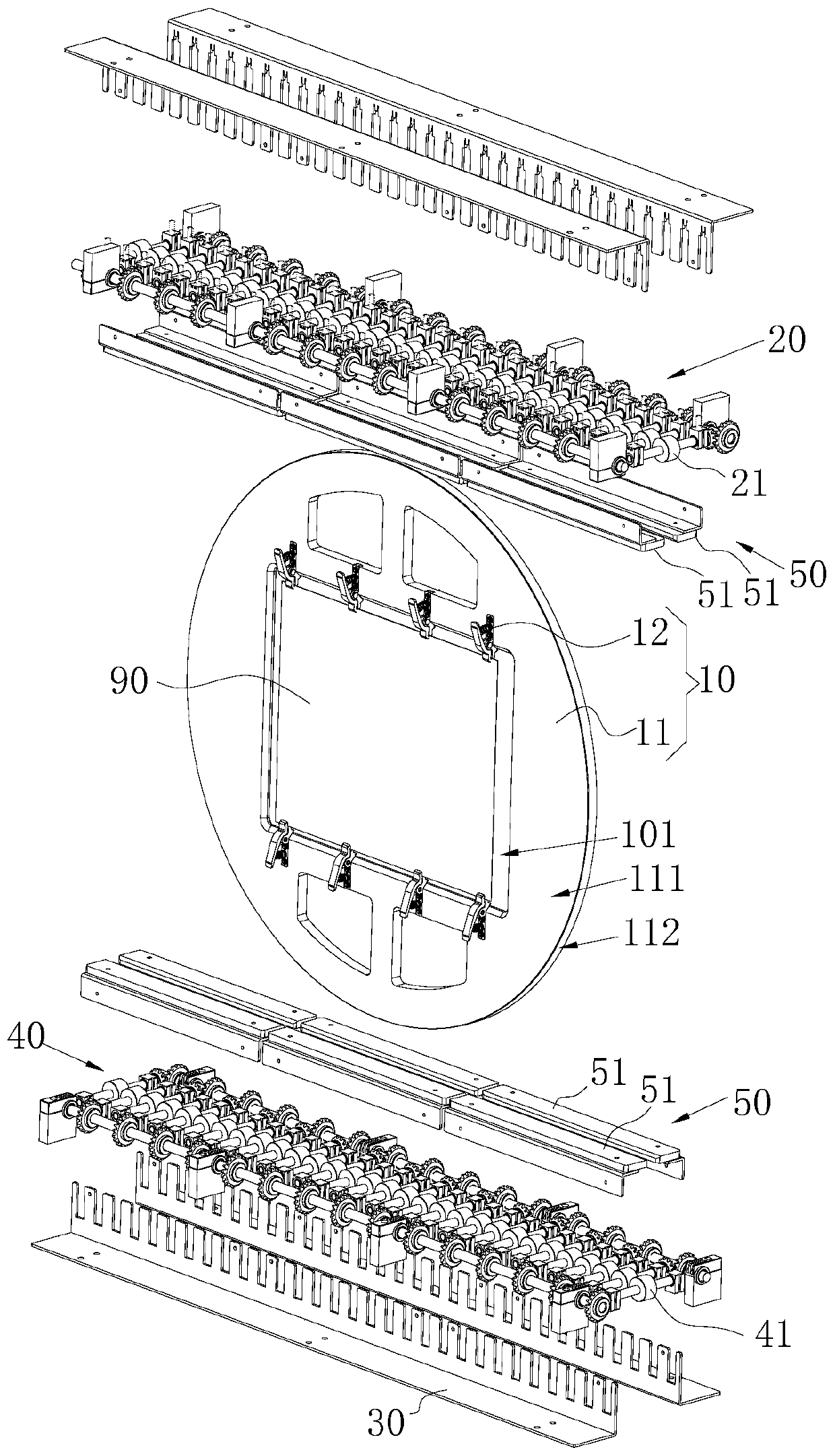

[0049] see figure 1 , the present invention provides a printed circuit board uniform solution processing device for processing printed circuit board 90, printed circuit board 90 is sheet-shaped and has a surface to be treated, wherein, printed circuit board 90 can have a surface to be treated, or can There are two opposite faces to be processed. It should be noted that the uniform liquid treatment device for printed circuit boards is especially used for processing the printed circuit boards 90 whose surface to be treated has been soaked with the chemical solution.

[0050] see figure 1 and figure 2 , The uniform solution processing device for printed circuit boards includes a loading mechanism 10 , a driving mechanism, a first supporting mechanism 30 and a first limiting mechanism 50 .

[0051] Wherein, the loading mechanism 10 is used to fix the printed circuit board 90 and make the plane where the printed circuit board 90 is located perpendicular to the horizontal plane....

Embodiment 2

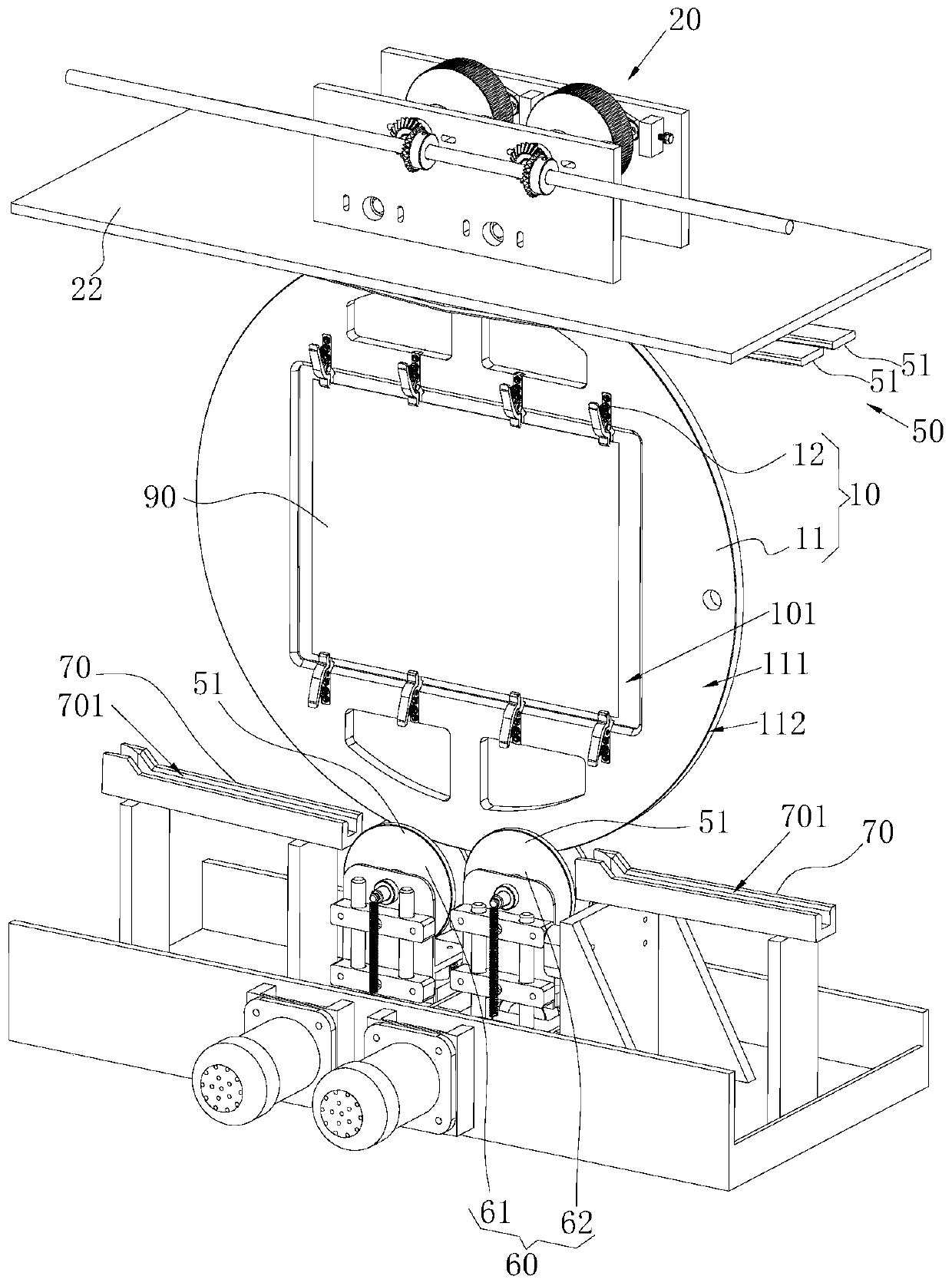

[0061] The second embodiment provides a printed circuit board uniform liquid processing device. Compared with the first embodiment, the difference lies in that the drive mechanism also includes a second The transmission assembly 60 , the first transmission assembly 20 and the second transmission assembly 60 are located at both ends of the loading tray 11 in the radial direction, so as to clamp the loading tray 11 together. Wherein, the second transmission assembly 60 is driven without power, and after the first transmission assembly 20 drives the loading tray 11 to rotate, the loading tray 11 can drive the second transmission assembly 60 to move through the friction force of the contact surface with the second transmission assembly 60 . The second transmission assembly 60 is preferably in contact with the edge surface 112 , and the first supporting mechanism 30 and the first transmission assembly 20 jointly clamp the loading tray 11 through the second transmission assembly 60 t...

Embodiment 3

[0065] The setting of the second limit mechanism in the second embodiment increases the frictional force when the loading tray 11 rotates. To solve this problem, please refer to image 3 and Figure 4 The present embodiment 3 provides a printed circuit board homogeneous liquid processing device. Compared with the embodiment 1, the difference lies in that the driving mechanism also includes a first supporting mechanism 30 and abutting against the loading tray 11 Two transmission components 60, the second transmission component 60 includes a first limiting wheel 61 and a second limiting wheel 62 arranged in sequence along the moving direction of the loading tray 11 and located on the moving path of the loading tray 11, the first limiting wheel Both the wheel 61 and the second limiting wheel 62 can move toward or away from the first transmission assembly 20 , and the second transmission assembly 60 has a limiting state and an advancing state.

[0066] When the second transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com