Copper surface roughening treatment solution and treatment method thereof

A technology for roughening and copper surface application in printed circuit liquid treatment, electrical components, printed circuit manufacturing, etc. It can solve problems such as high production costs and insufficient profitability, and achieve enhanced bonding, improved oxidation efficiency, and delayed decomposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

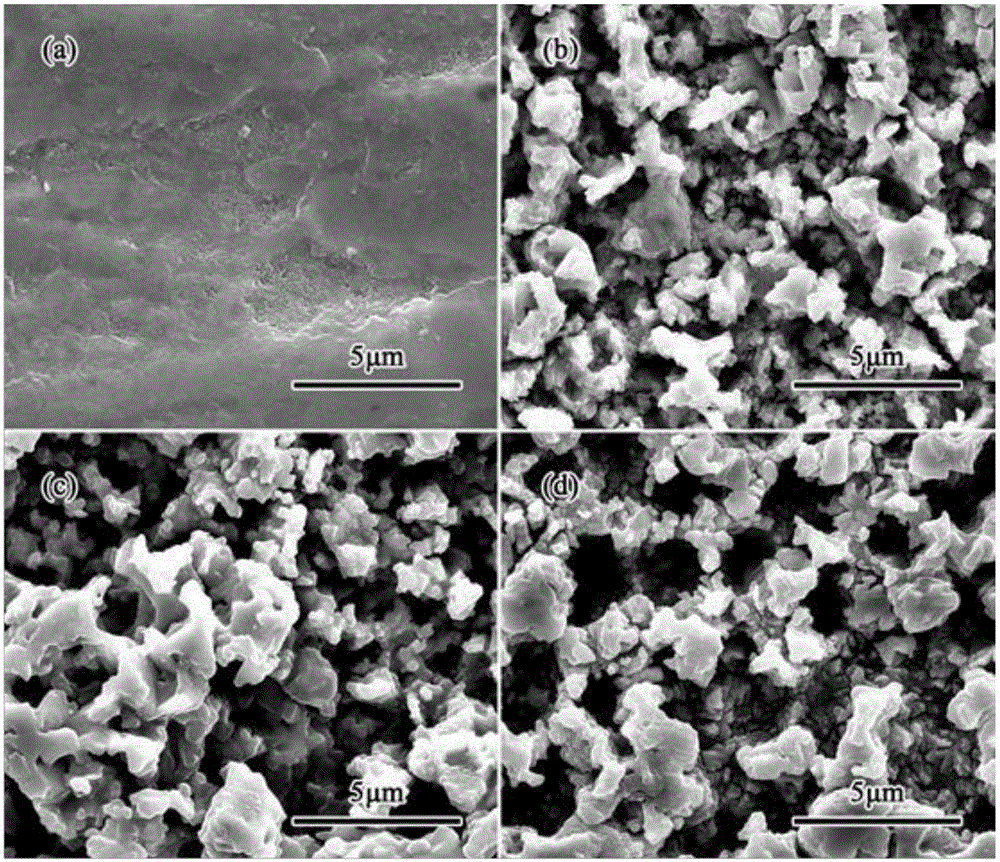

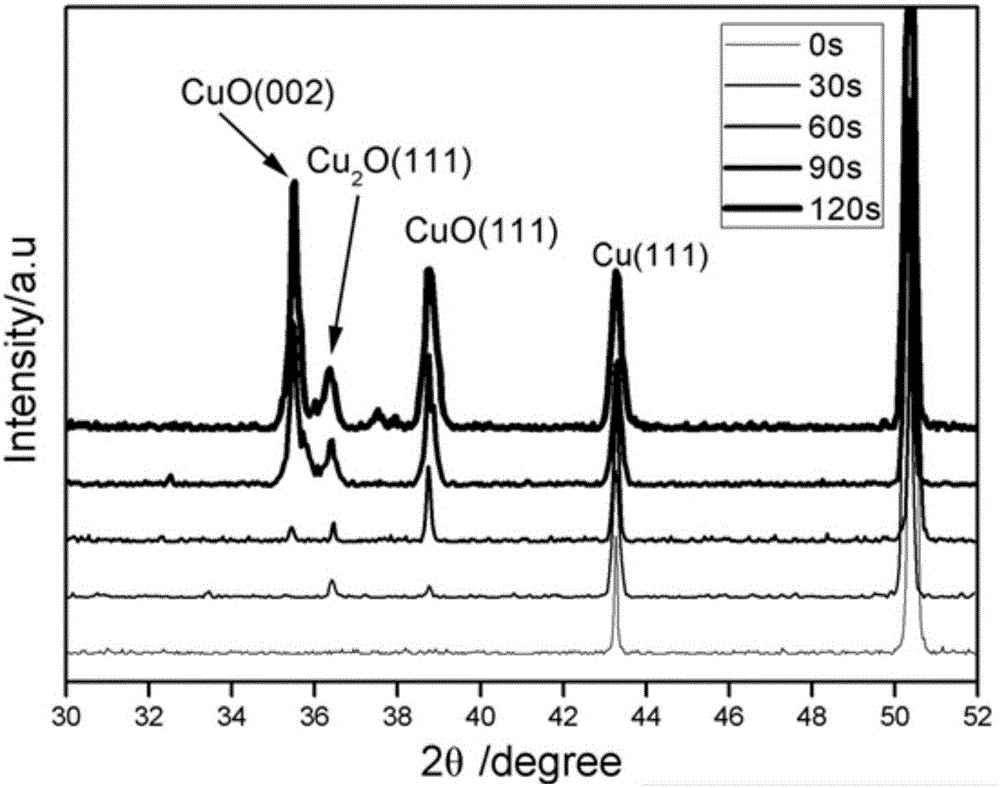

Method used

Image

Examples

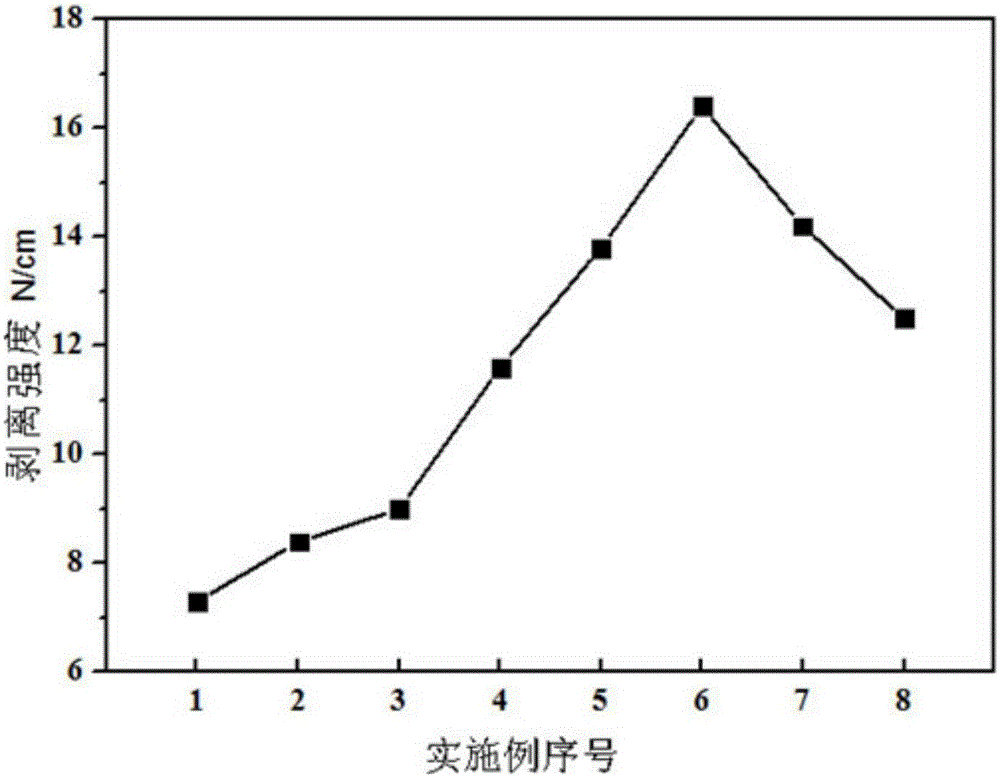

Embodiment 1

[0057] A kind of copper surface roughening treatment liquid of the present embodiment comprises following components:

[0058] h 2 SO 4 (98wt%) 95g / L Organosilane coupling agent 3.5g / L h 2 o 2 (30v / v%) 60mL / L Zinc sulfate 10g / L Benzenesulfonic acid 100mg / L Benzotriazole 0.5g / L 1-Butyl-3 methylimidazolium tetrafluoroborate 0.5g / L Deionized water Dilute to 1L

Embodiment 2

[0060] A kind of copper surface roughening treatment liquid of the present embodiment comprises following components:

[0061] h 2 SO 4 (98%) 95g / L Organosilane coupling agent 3.5g / L h 2 o 2 (30%) 60mL / L Zinc sulfate 10g / L Benzenesulfonic acid 100mg / L Benzotriazole 1g / L dodecyl mercaptan 1.5g / L Deionized water Dilute to 1L

Embodiment 3

[0063] A kind of copper surface roughening treatment liquid of the present embodiment comprises following components:

[0064] h 2 SO 4 (98%) 95g / L Organosilane coupling agent 3.5g / L h 2 o 2 (30%) 60mL / L Zinc sulfate 10g / L

[0065] Benzenesulfonic acid 100mg / L Benzotriazole 2.5g / L dodecyl mercaptan 2.5g / L Deionized water Dilute to 1L

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com