Etching device and circuit board etching method

A technology for etching devices and circuit boards, which is applied in printed circuits, spray devices, and chemical/electrolytic methods to remove conductive materials, etc., can solve the problems of fast flow, etching, and updating, and can prevent the pool effect and improve uniformity. performance, preventing over-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The etching device and the method for etching a circuit board provided by the technical solution will be described in detail below in conjunction with multiple drawings and multiple embodiments.

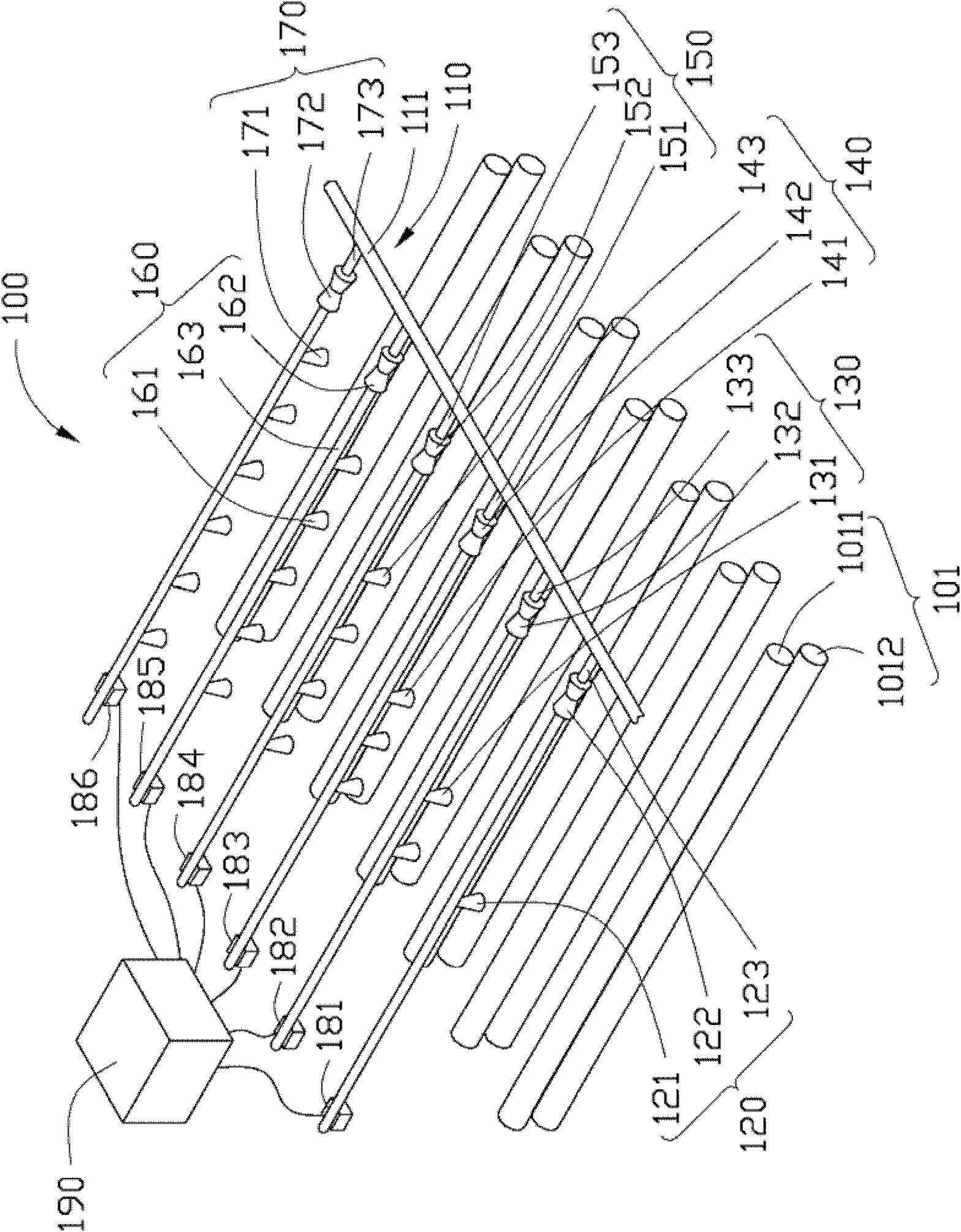

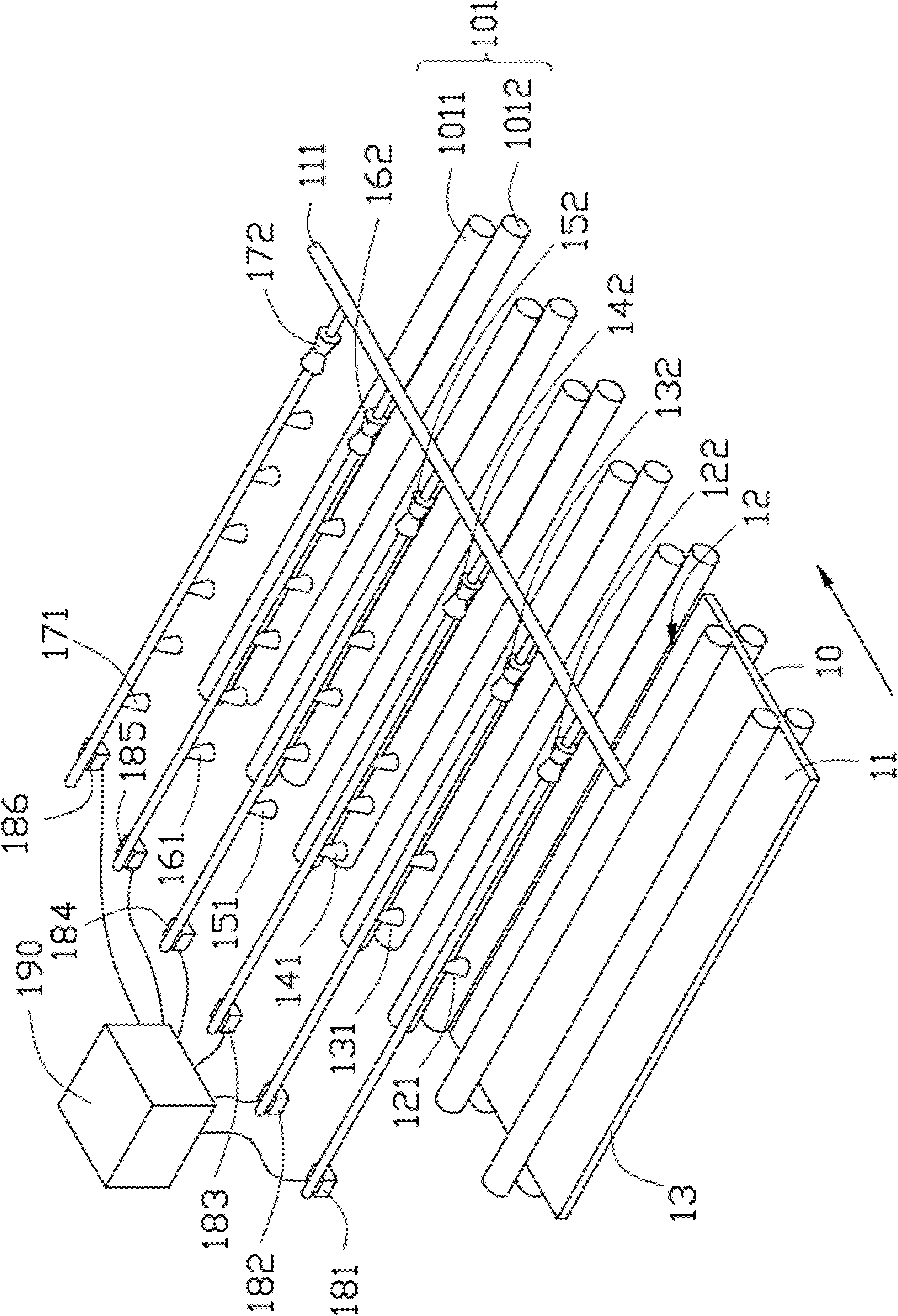

[0058] see figure 1 , the etching device 100 provided by the first embodiment of the technical solution includes an infusion device 110, a first nozzle 120, a second nozzle 130, a third nozzle 140, a fourth nozzle 150, a fifth nozzle 160, a sixth nozzle Nozzle 170, first sensor 181, second sensor 182, third sensor 183, fourth sensor 184, fifth sensor 185, sixth sensor 186, controller 190 and Delivery device 101.

[0059]In this embodiment, the infusion device 110 includes an infusion tube 111 . The infusion pipe 111 is used to supply etching solution to the first nozzle 120 , the second nozzle 130 , the third nozzle 140 , the fourth nozzle 150 , the fifth nozzle 160 and the sixth nozzle 170 . Certainly, a valve may be installed on the infusion tube 111 to control whether th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com