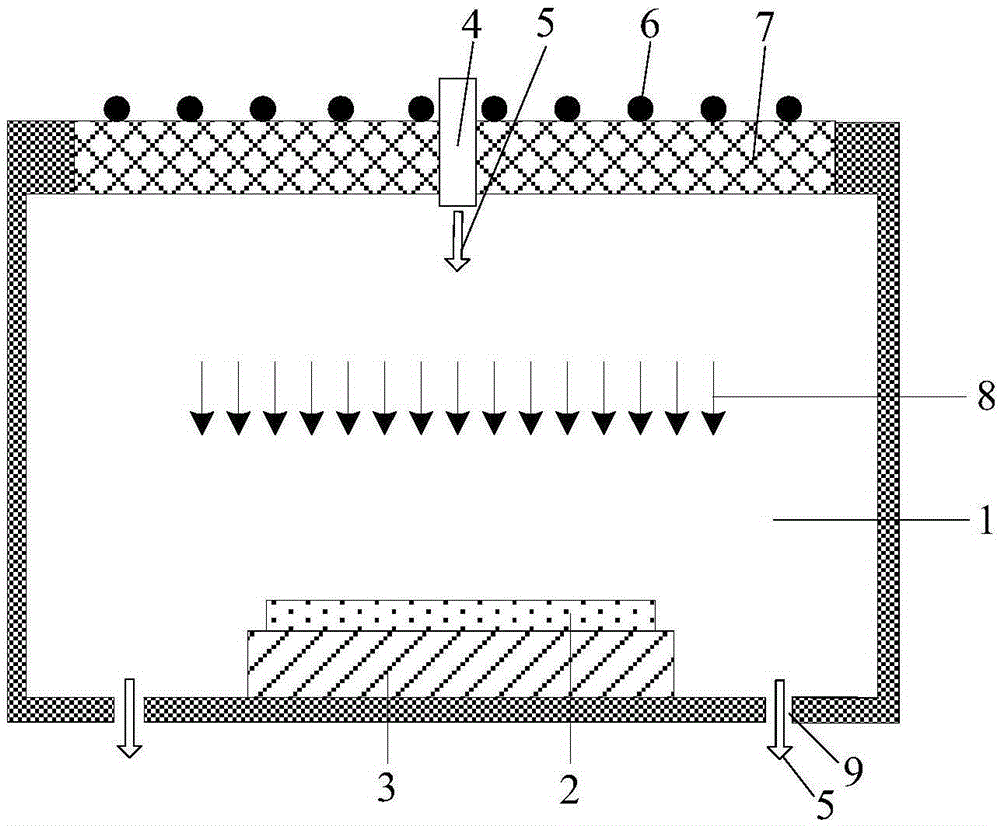

Wafer etching device and method

A technology for etching devices and wafers, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of reduction and no obvious improvement in the yield rate of integrated circuits, achieve good isolation performance, and avoid trenches Decrease in isolation performance and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] As described in the background art, in the prior art, the etching uniformity is improved by rotating the placing table 3 or setting a rotating shaft under the wafer 2 to drive the wafer 2 to rotate, but this solution does not make the integrated circuit good. The rate has been significantly improved, and sometimes even the yield rate of integrated circuits will be reduced. The inventor of the present invention finds through a large amount of research and experiment, and the main cause of above-mentioned problem is:

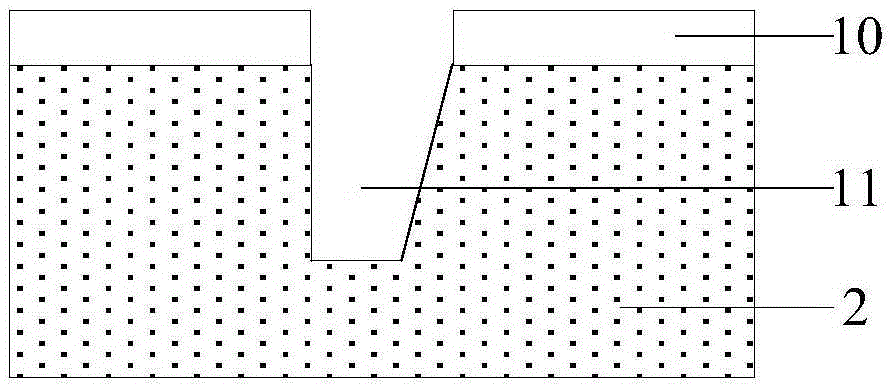

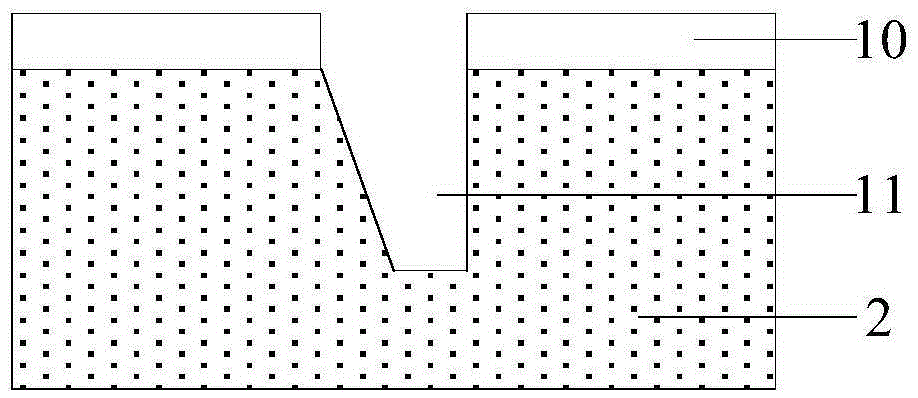

[0041] Such as Figure 2a with Figure 2b As shown, in the prior art, the placement table 3 can only drive the wafer 2 to rotate in one direction, that is, only rotate clockwise or only counterclockwise, because the etching process is to transfer the pattern on the mask 10 to the wafer 2, so the unidirectional rotation of the wafer 2 will deflect the pattern transmission at a certain angle, and finally cause the left and right side walls of the trench 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com