Equipment and method for etching silicon nitride thin film

A silicon nitride film and etching technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of limited improvement and uneven etching, and achieve the promotion of dissolution rate, improvement of mixing uniformity, and improvement of etching The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

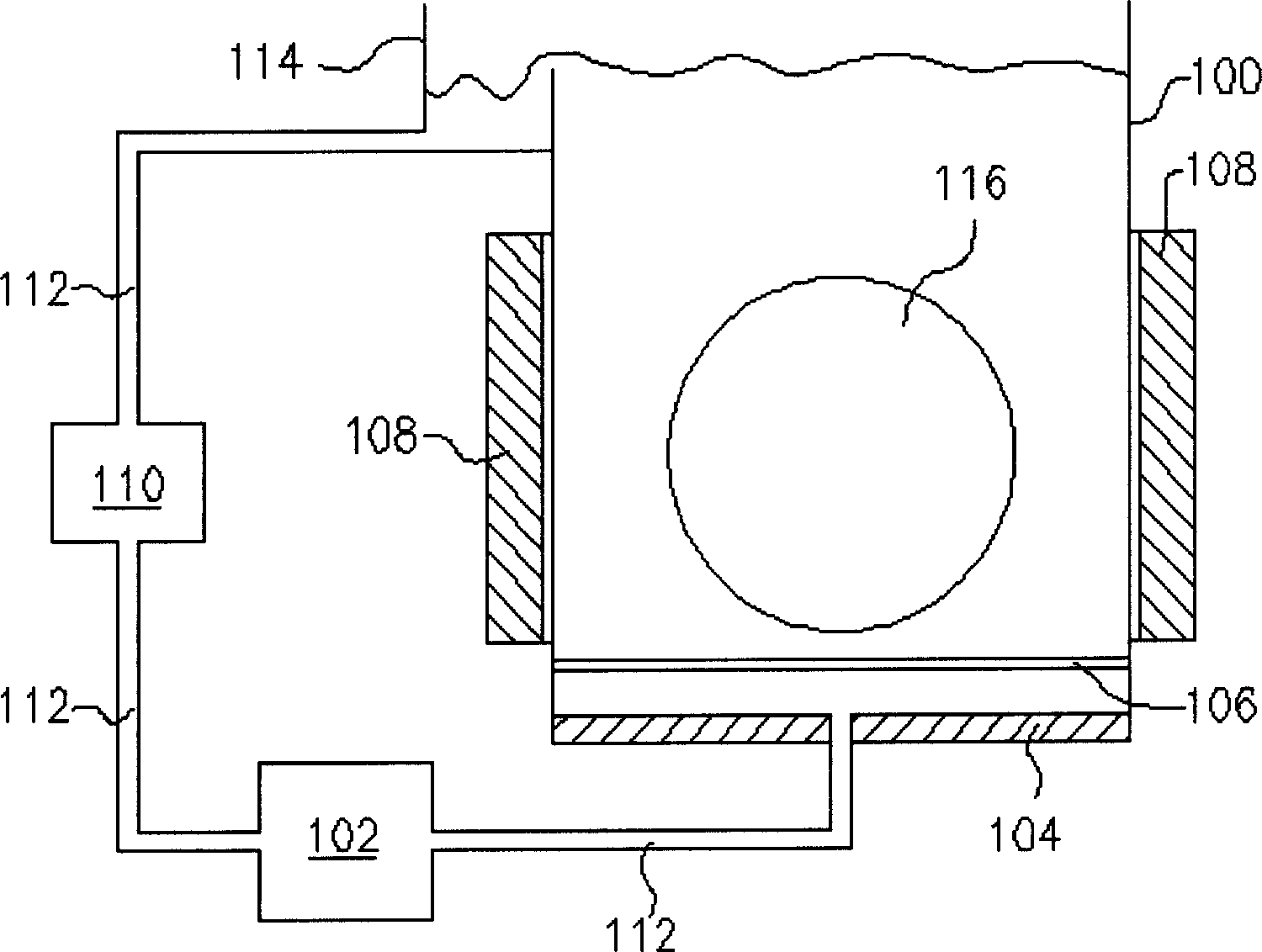

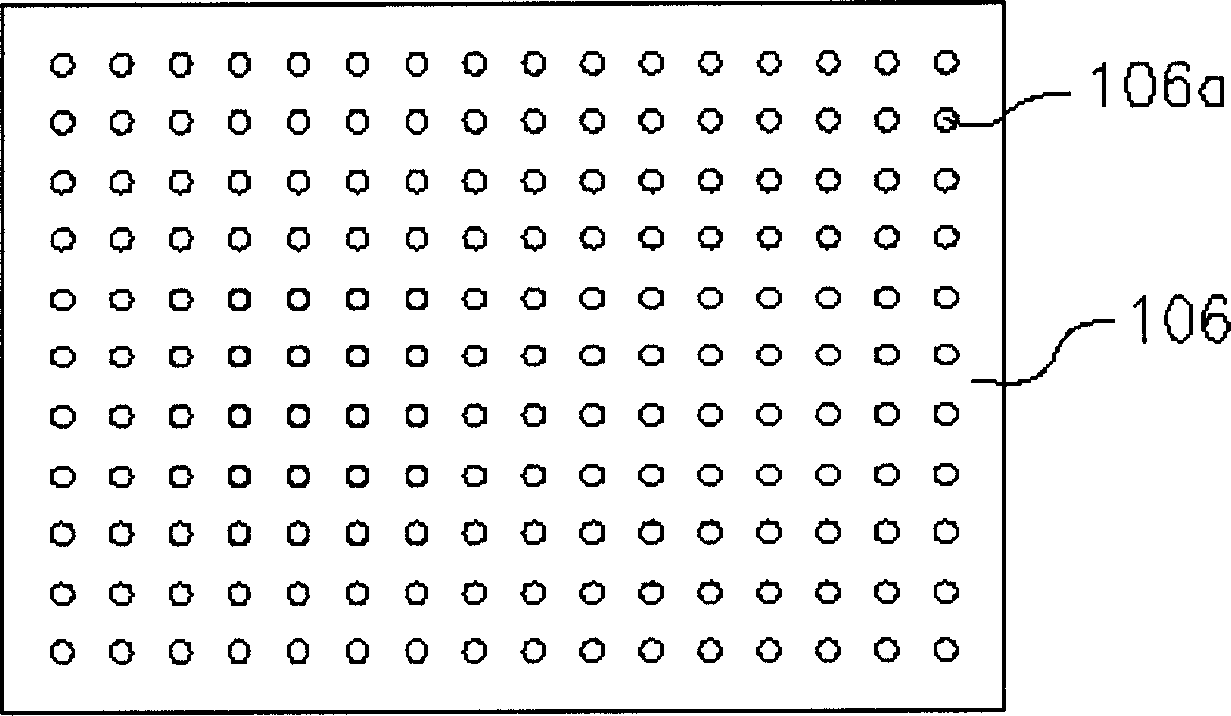

[0026] Please refer to figure 1 , which is a schematic diagram of an apparatus for etching a silicon nitride film according to a preferred embodiment of the present invention. This equipment is composed of a phosphoric acid tank 100 , a water adding unit 102 , a pipe fitting 112 , a heating device 104 , an acoustic wave generator 108 and a baffle 106 .

[0027] Wherein, the phosphoric acid tank 100 is filled with a concentrated phosphoric acid solution, such as a commercially available phosphoric acid solution with a concentration of 86%. The phosphoric acid tank 100 and the water adding unit 102 are communicated through a pipe fitting 112, and the water adding unit 102 is connected to a pressurizing device 110, and one end of the pipe fitting 112 is connected to the bottom of the phosphoric acid tank 100, so that the water adding unit 102 can be regularly A certain amount of water is injected from the bottom of the phosphoric acid tank 100 .

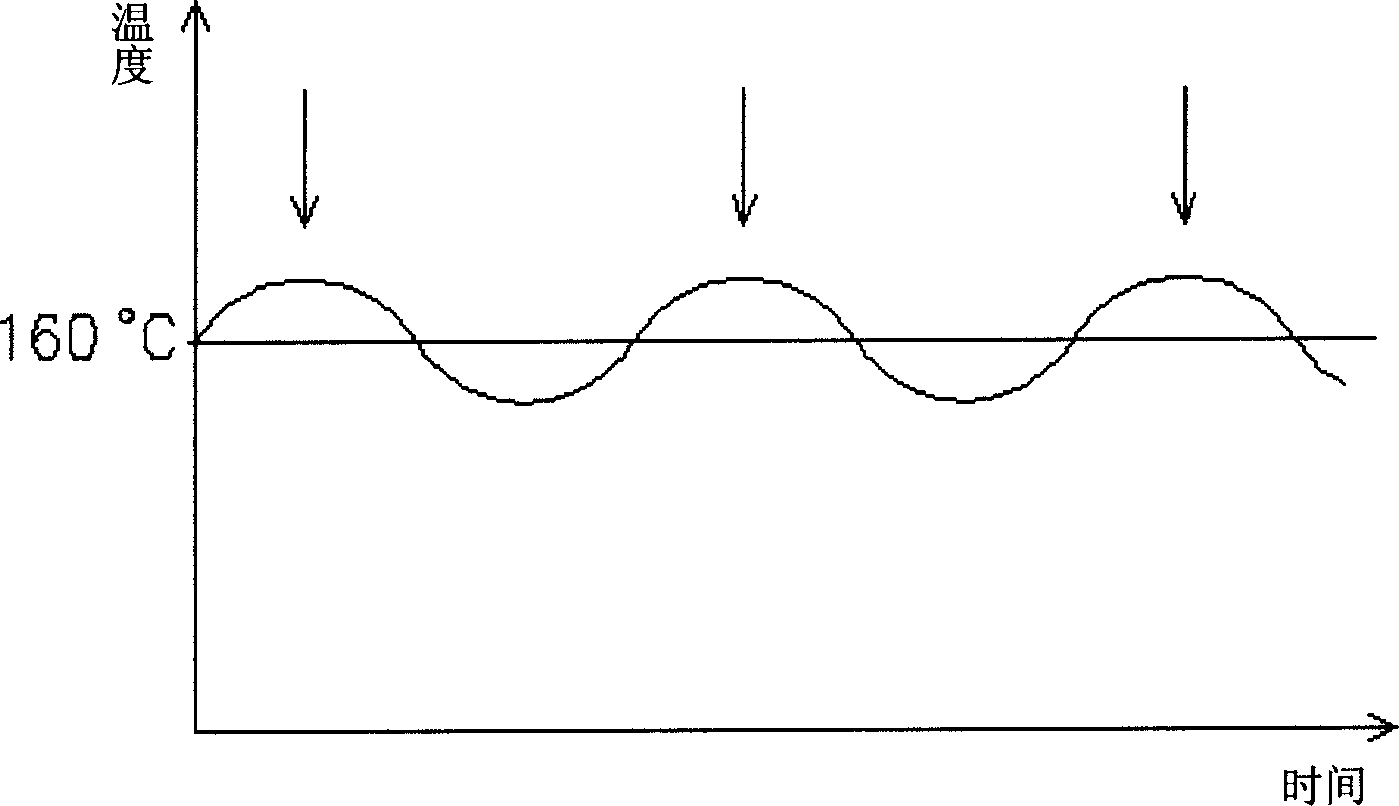

[0028] In a preferred embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com