Transfer apparatus, cleaning apparatus, chemical processing apparatus, and method for manufacturing circuit substrate

a technology of chemical processing and transfer apparatus, which is applied in the direction of cleaning with liquids, charge manipulation, furnaces, etc., can solve the problems of difficult to apply a large amount of tension to the tape substrate, complex transfer control, and deterioration of the quality of the tape substrate, so as to prevent the tension from increasing, reduce the tension applied to the object to be transferred, and prevent the effect of complex transfer control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

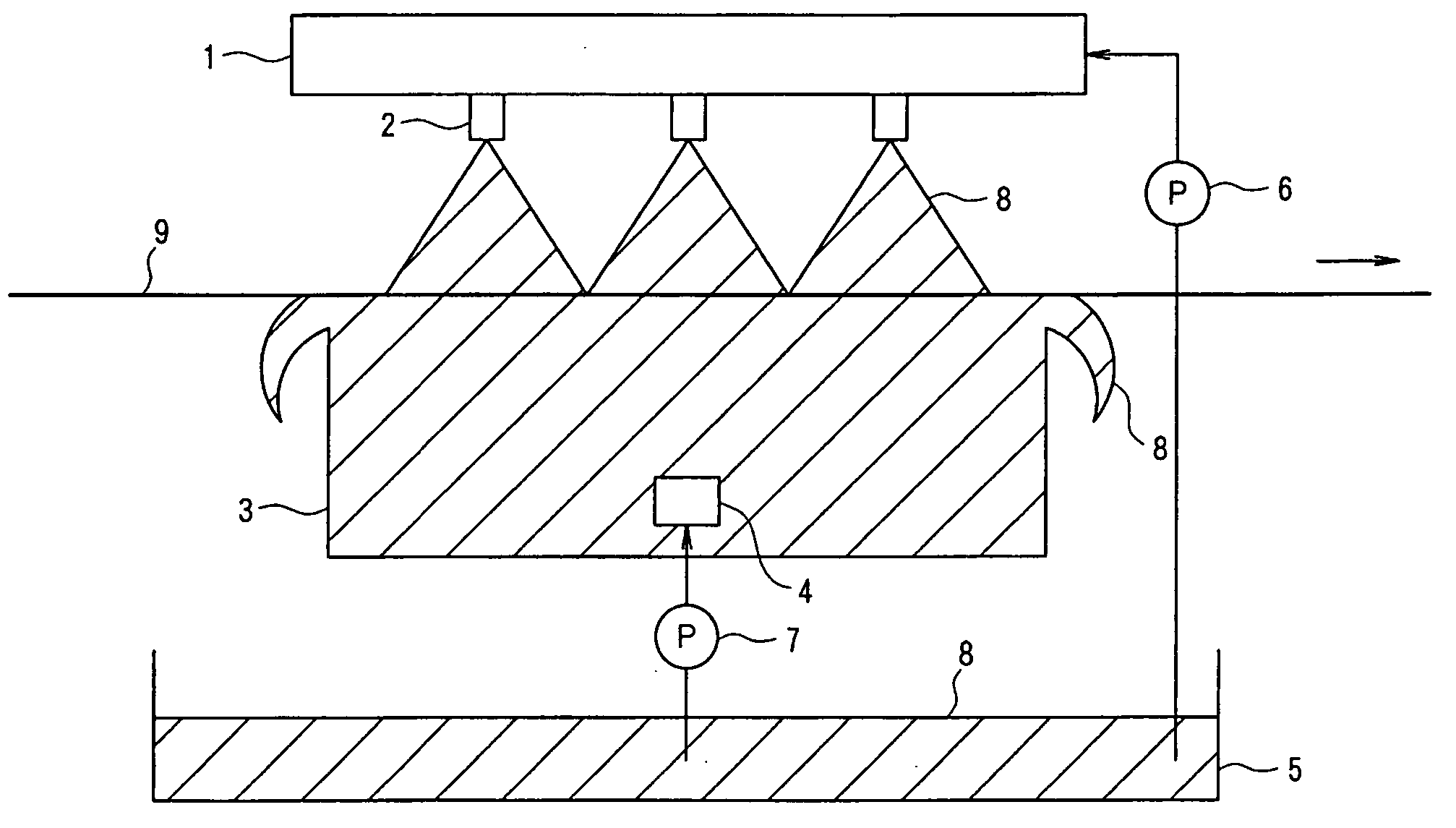

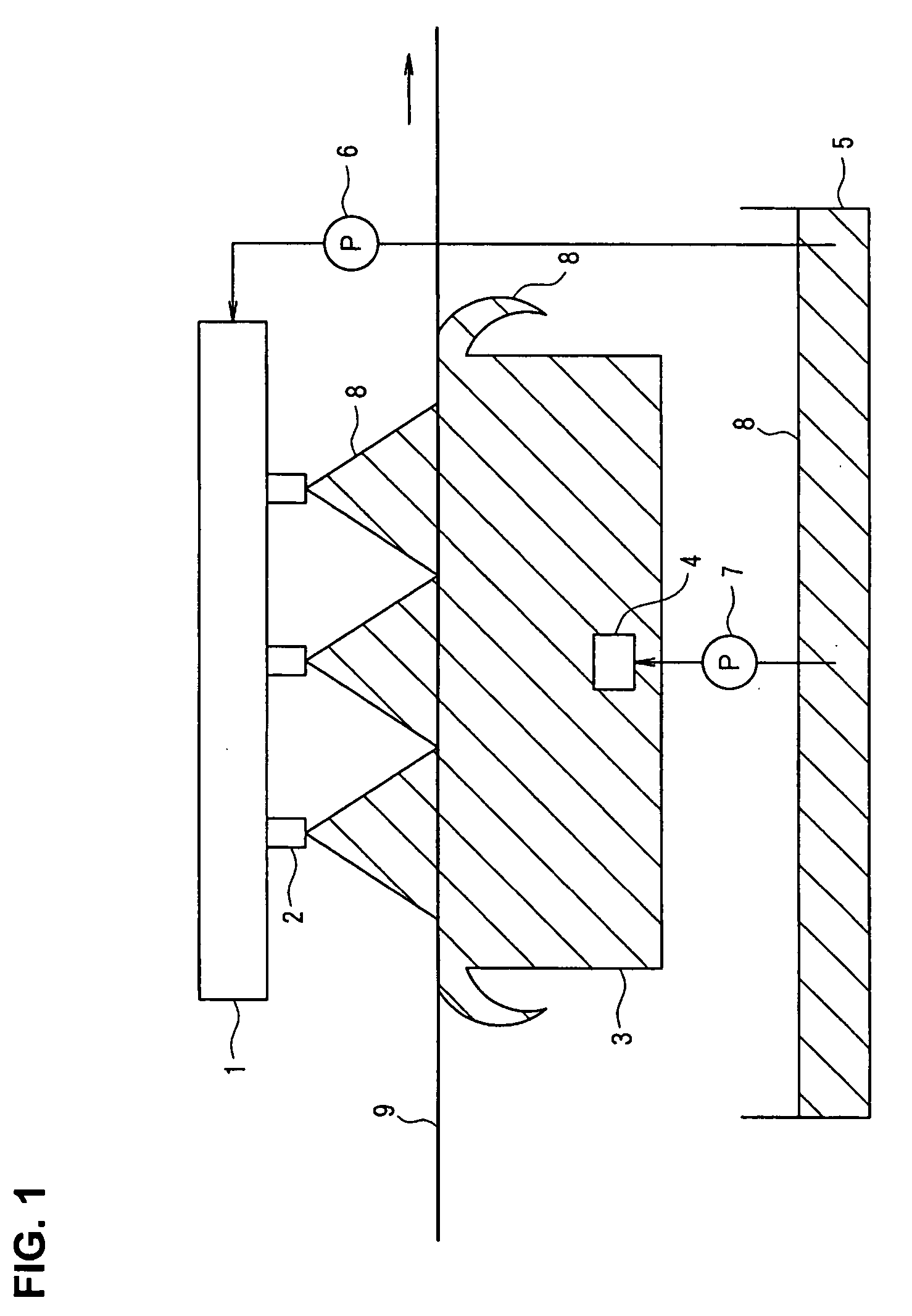

[0030]FIG. 1 schematically shows a cross section of the structure of a cleaning apparatus in accordance with the present invention.

[0031] Referring to FIG. 1, a cleaning liquid reservoir tank 3 stores cleaning liquid 8, and a cleaning liquid supply unit 4 is provided for overflowing the cleaning liquid 8 from the cleaning liquid reservoir tank 3. Also, a cleaning liquid jetting unit 1 for jetting the cleaning liquid 8 is provided above the cleaning liquid reservoir tank 3, and nozzles 2 that jet the cleaning liquid 8 onto a tape substrate 9 are provided at the cleaning liquid jetting unit 1.

[0032] Also, below the cleaning liquid reservoir tank 3 is provided a cleaning liquid collecting tank 5 for collecting the cleaning liquid 8 that is jetted from the cleaning liquid jetting unit 1 and the cleaning liquid 8 that overflows from the cleaning liquid reservoir tank 3. Further, a pump 6 is provided for sending the cleaning liquid 8 collected in the cleaning liquid collecting tank 5 to ...

second embodiment

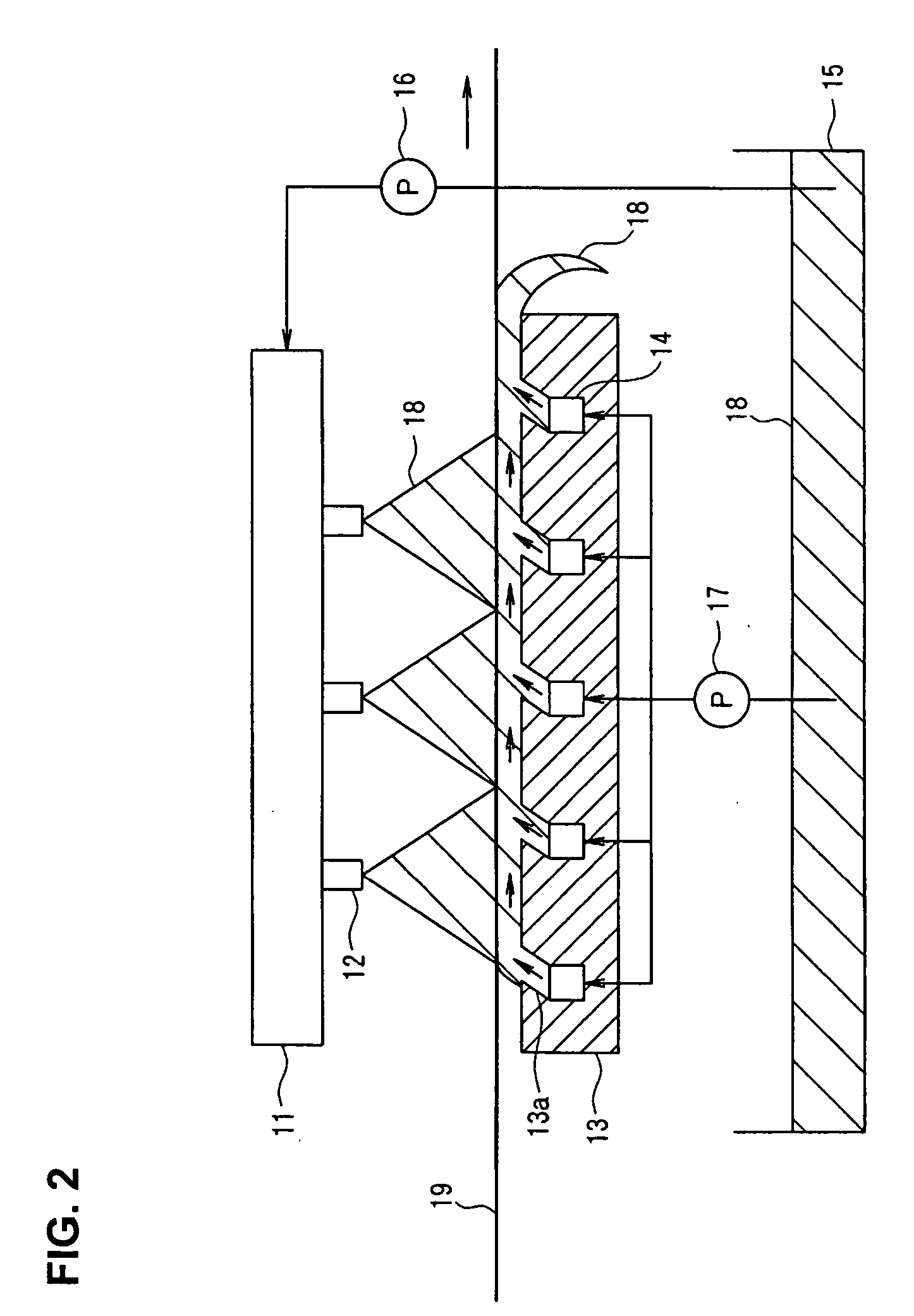

[0039]FIG. 2 schematically shows a cross section of the structure of a cleaning apparatus in accordance with the present invention. Referring to FIG. 2, a cleaning liquid flowing unit 13 that flows cleaning liquid 18 is provided with cleaning liquid supply units 14 that supply the cleaning liquid 18 onto the cleaning liquid flowing unit 13, and cleaning liquid jetting nozzles 13a for jetting the cleaning liquid 18 sent out from the cleaning liquid supply units 14 along a transfer direction of a tape substrate 19. Also, a cleaning liquid jetting unit 11 for jetting the cleaning liquid 18 is provided above the cleaning liquid flowing unit 13, and nozzles 12 that jet the cleaning liquid 18 onto the tape substrate 19 are provided at the cleaning liquid jetting unit 11.

[0040] Also, below the cleaning liquid flowing unit 13 is provided a cleaning liquid collecting tank 15 for collecting the cleaning liquid 18 that is jetted from the cleaning liquid jetting unit 11 and the cleaning liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com