Method, retaining means, apparatus and system for transporting a flat material feedstock, and loading or unloading device

A technology for holding devices and conveying equipment, which is applied in the direction of conveyor objects, transportation and packaging, lighting and heating equipment, etc., and can solve problems such as movement, poor inherent stability of materials to be processed, and difficulty in conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

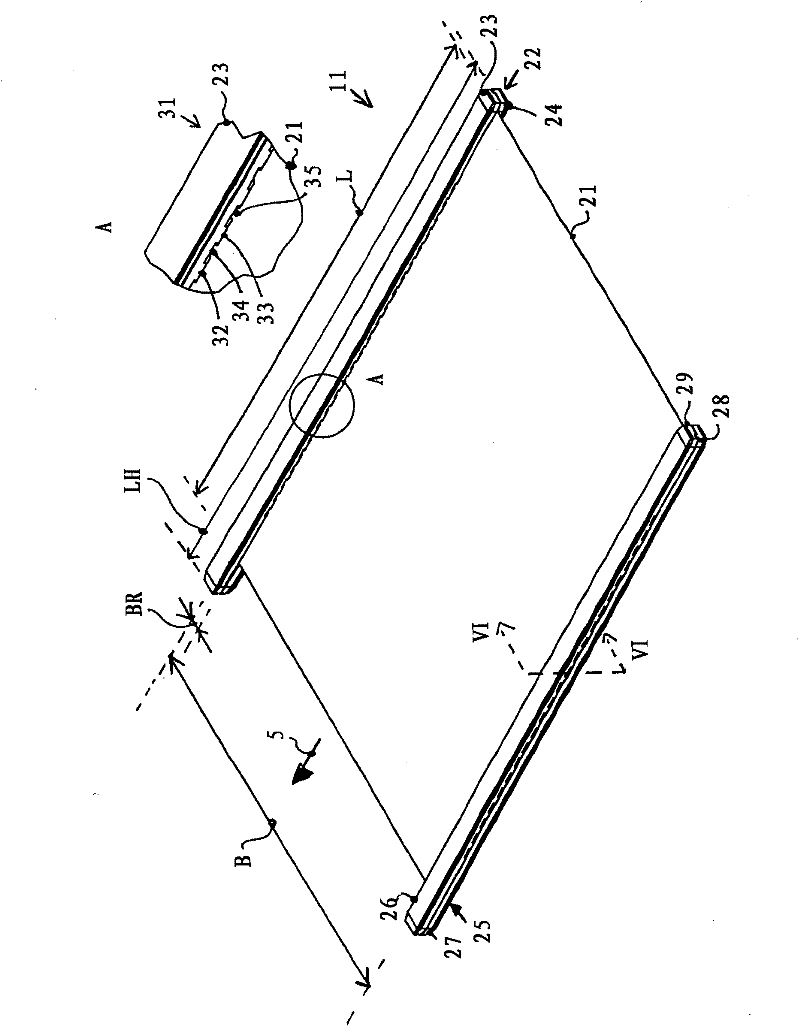

[0050] Directional or positional details relating to the material to be processed are conventionally indicated with reference to the conveying direction. The direction parallel or antiparallel to the conveying direction during the conveying of the material to be processed will be called "longitudinal direction", and the direction in the conveying plane perpendicular to the conveying direction will be called "width direction" of the material to be processed .

[0051] A "detachable coupling" of elements or devices will be understood to mean such a coupling that enables the elements or devices to be separated from each other without damaging or destroying said elements or devices. A "detachable coupling" between the holding device and the material to be treated will thus be understood to mean that the holding device can be removed from the material to be treated without destroying the holding device or the material or damaging them. functional way to damage their joins. A "det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com