Recyclable azeotropic cleaning agent for industrial use, method for cleaning article, method for recycling azeotropic cleaning agent for industrial use, azeotropic cleaning agent for industrial use recycled by said recycling method, and cleaning/recycling apparatus

An industrial and cleaning agent technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, detergent compositions, etc., to achieve the effects of excellent removal ability, no residue, and easy drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

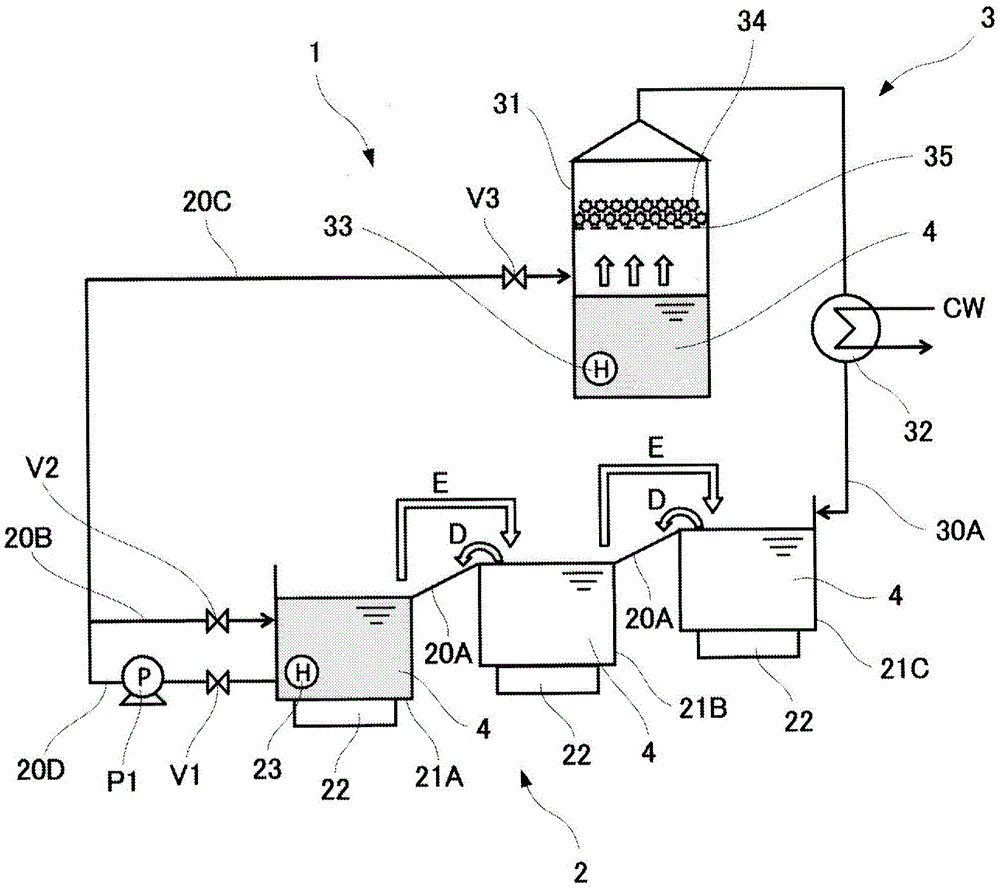

[0084] figure 1 The washing and regenerating device 1 of the first embodiment is shown. The cleaning and regenerating device 1 is equipped with a cleaning mechanism 2 that uses an industrial azeotropic cleaning agent 4 to clean articles with industrial dirt attached, and regenerates the waste liquid of the industrial azeotropic cleaning agent 4 used in cleaning the articles in the cleaning mechanism 2. The regenerative mechanism3.

[0085] The cleaning mechanism 2 carries out ultrasonic cleaning, and is equipped with a first liquid tank 21A, a second liquid tank 21B, and a third liquid tank 21C for storing an industrial azeotropic cleaning agent 4, and is arranged on the bottom of each liquid tank 21A, 21B, and 21C. The ultrasonic vibrators 22 that irradiate ultrasonic waves are applied to the insides of the liquid tanks 21A, 21B, and 21C. Any known vibrator, such as a piezoelectric element or an electromagnetic vibrator, can be used as the ultrasonic vibrator 22 . In the f...

no. 2 approach

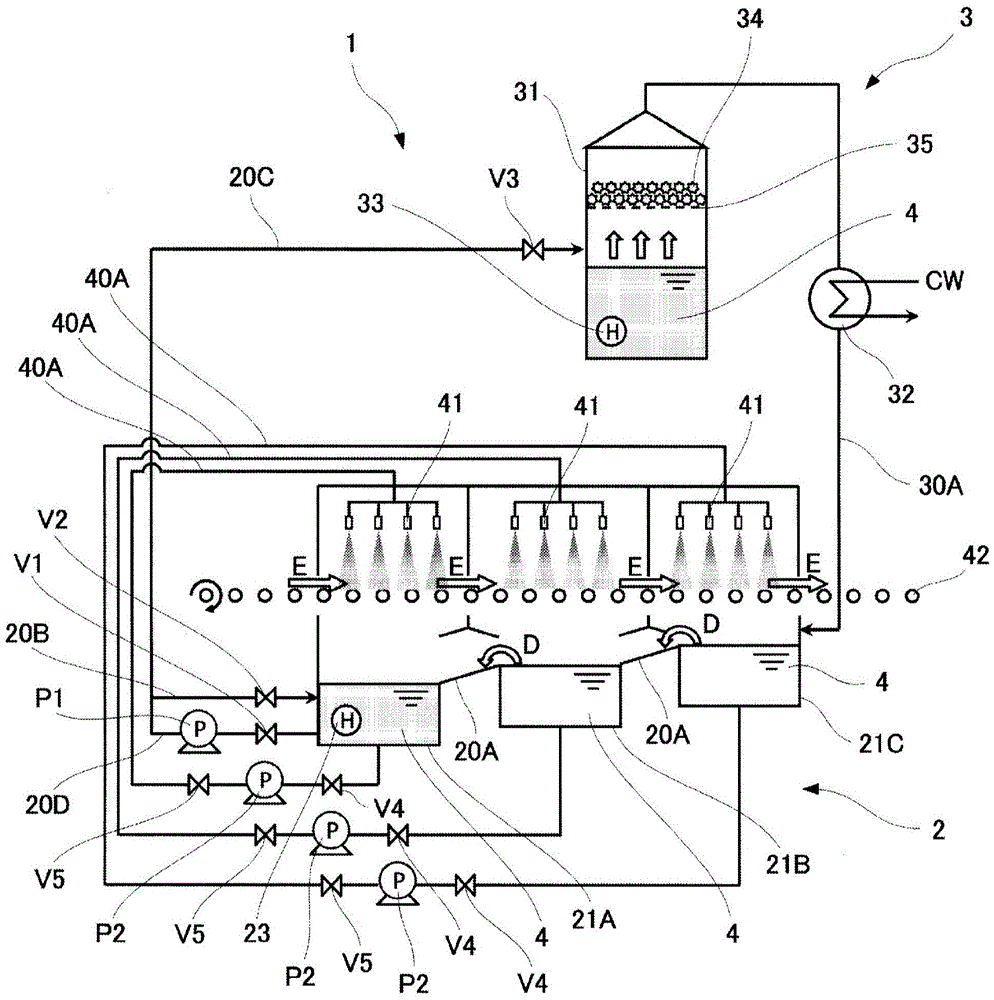

[0096] figure 2 The cleaning and regenerating device 1 of the second embodiment is shown. The cleaning and regenerating device 1 is the same as the first embodiment, and includes a cleaning mechanism 2 that uses an industrial azeotropic cleaning agent 4 to clean articles adhering with industrial dirt, and an industrial azeotropic cleaning mechanism 2 that is used to clean the articles. Regeneration mechanism 3 for regenerating the waste liquid of agent 4. It should be noted that the playback mechanism 3 has the same configuration as that of the above-mentioned first embodiment, so the same reference numerals are assigned and detailed description thereof will be omitted.

[0097] The cleaning mechanism 2 performs spray cleaning, and is equipped with a first liquid tank 21A, a second liquid tank 21B, and a third liquid tank 21C for storing an industrial azeotropic cleaning agent 4, and is arranged above each liquid tank 21A, 21B, and 21C and sprays The spray nozzle 41 of the ...

Embodiment

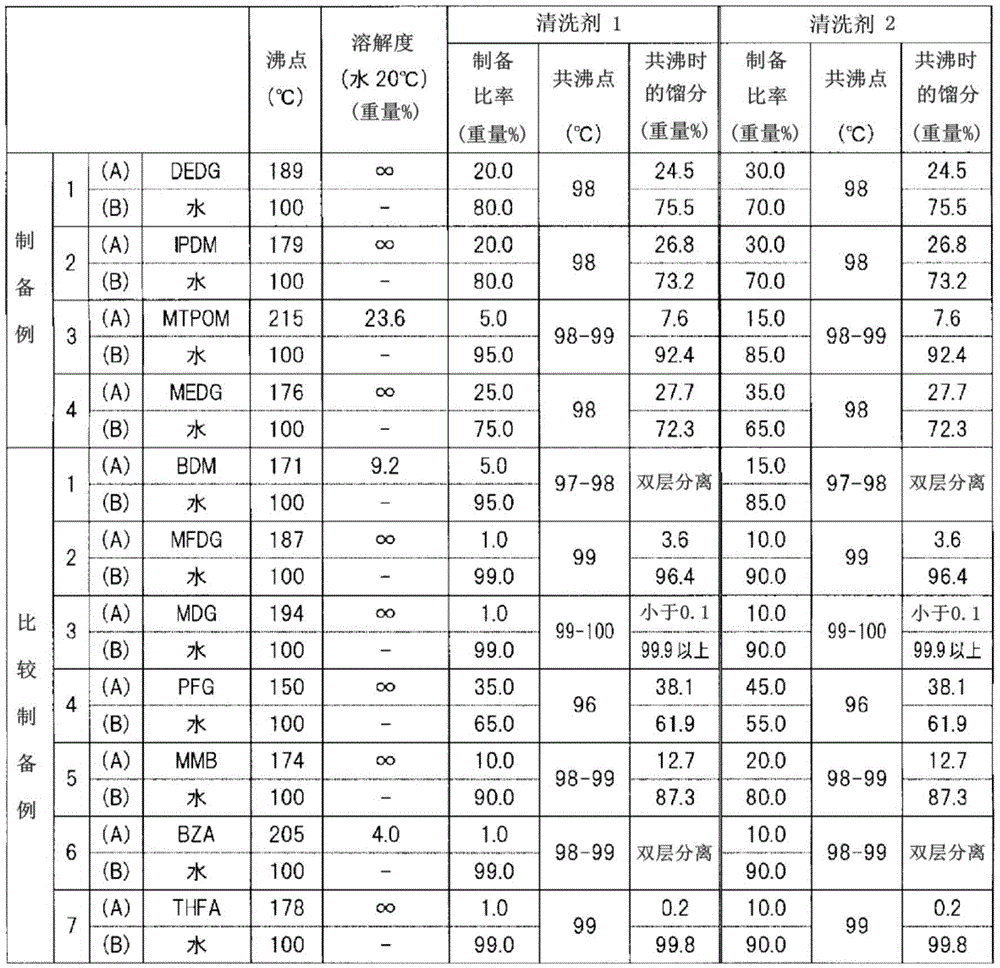

[0105] The present invention will be specifically described by way of examples. However, the scope of the present invention is not limited by these Examples.

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com