Surface treating apparatus, tank body and squirting device

A technology of surface treatment device and tank, which is applied in the direction of printed circuit liquid treatment, plating tank, liquid chemical plating, etc., which can solve problems such as large-scale, inability to process the surface and back of the workpiece, and inability to obtain the quality of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] 1. Structure of surface treatment device 300

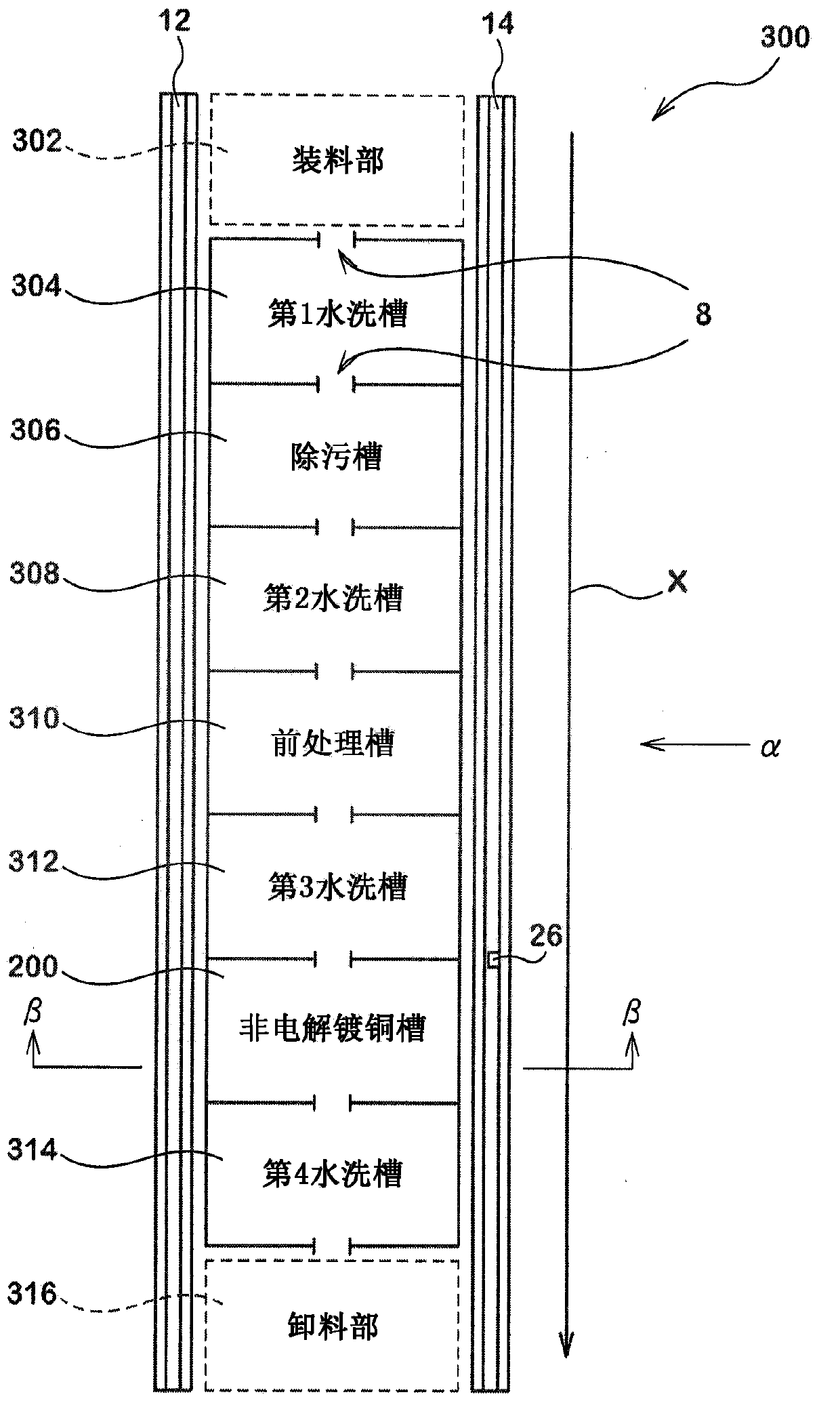

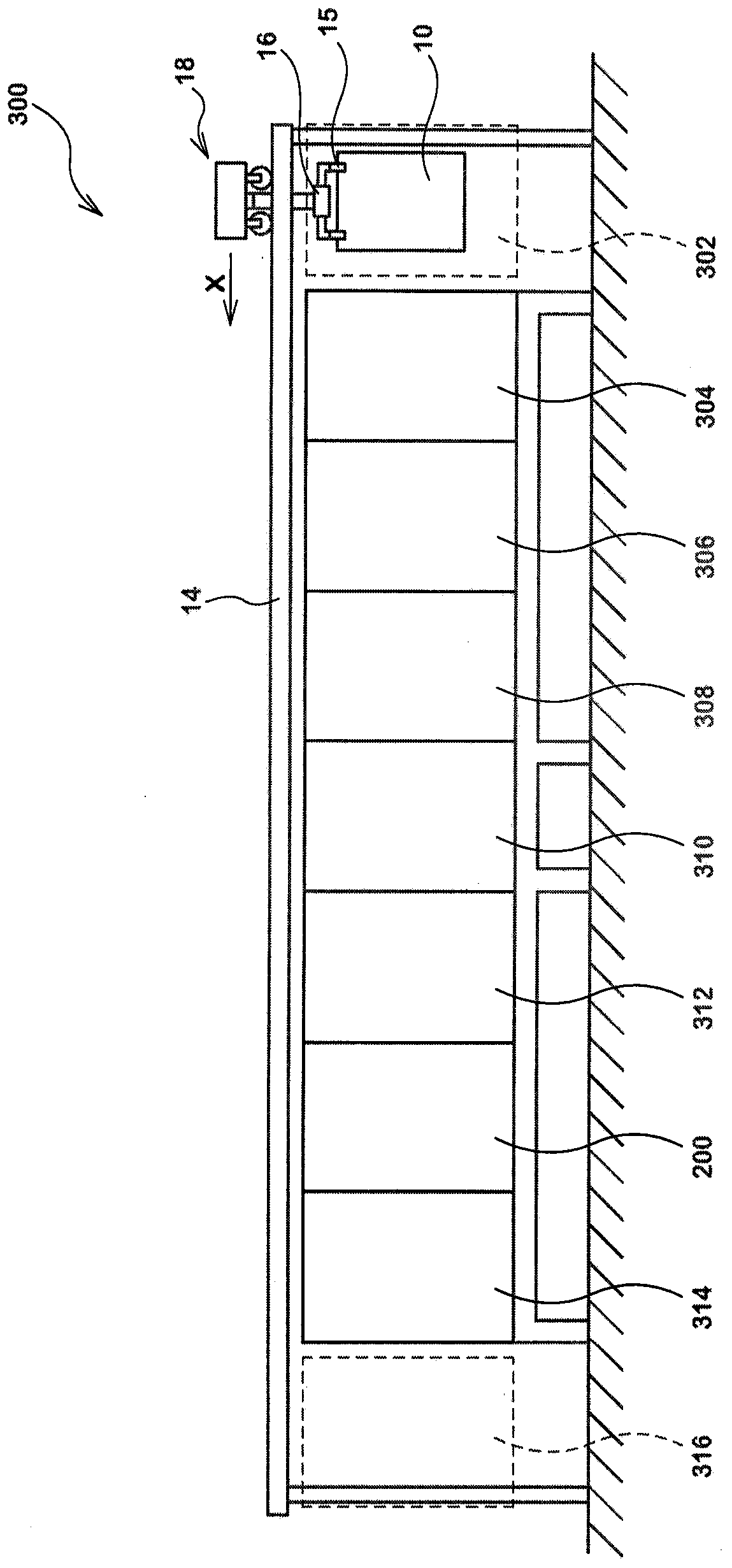

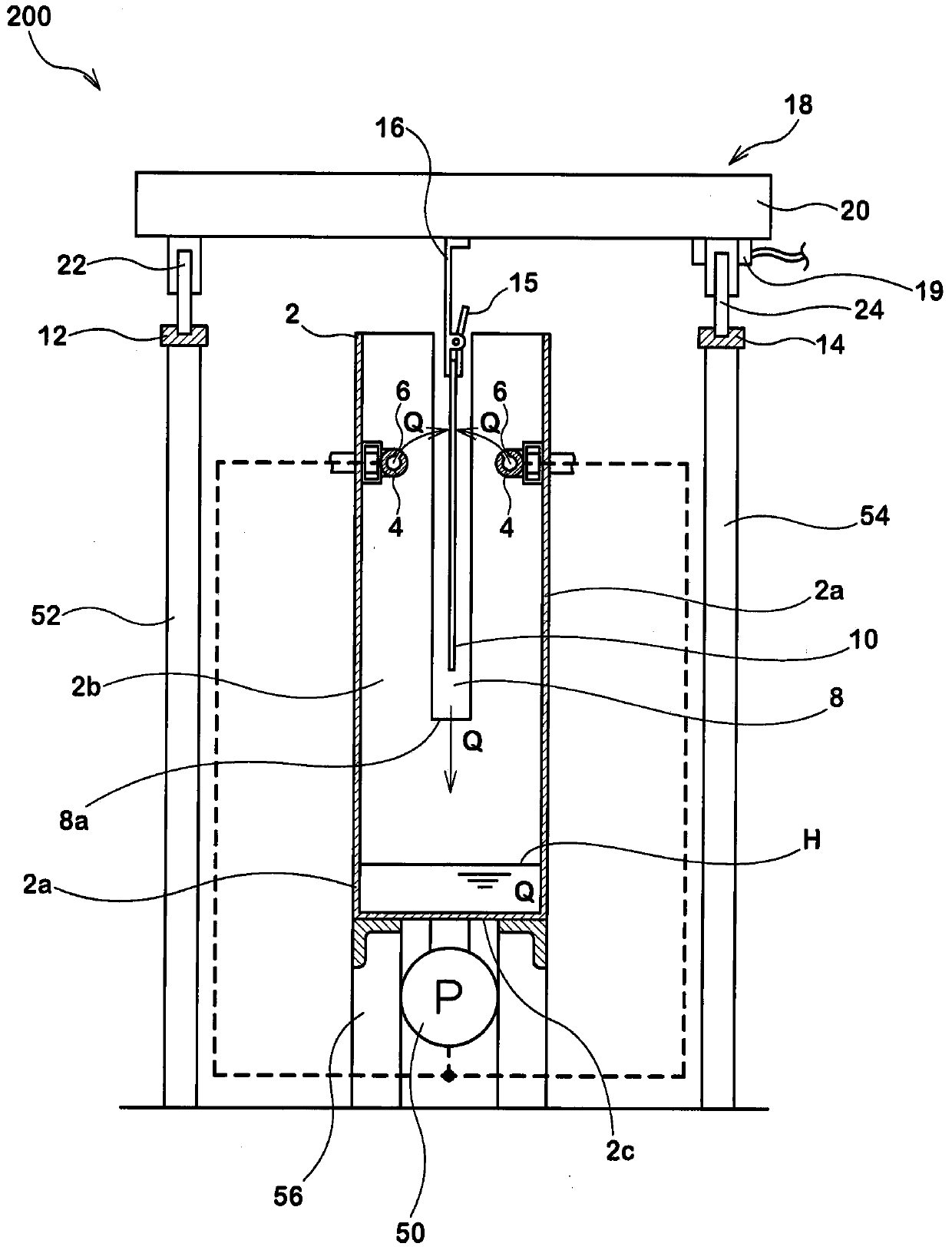

[0092] First, use figure 1 and figure 2 The structure of the surface treatment apparatus 300 of this invention is demonstrated. and, figure 1 It is a configuration diagram of the surface treatment apparatus 300 viewed from above. figure 2 is viewed from the direction of α figure 1 A side view of the surface treatment device 300 is shown. and, in figure 1 in, omitted figure 2 A transport hanger 16 and a transport mechanism 18 are shown.

[0093] Such as figure 1 As shown, in the surface treatment device 300, along the plate-shaped workpiece 10 ( figure 2 ) in the conveying direction X is provided with the loading part 302, the first washing tank 304, the decontamination tank 306, the second washing tank 308, the pretreatment tank 310, the third washing tank 312, the electroless copper plating tank 200, the fourth The washing tank 314 and the discharge unit 316 perform each process required for electroless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com