Device and method for electrolytically treating work pieces

A technology for electrolytic treatment and workpiece, applied in electrolytic components, printed circuit liquid treatment, electrolytic process, etc., can solve problems such as unproven, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

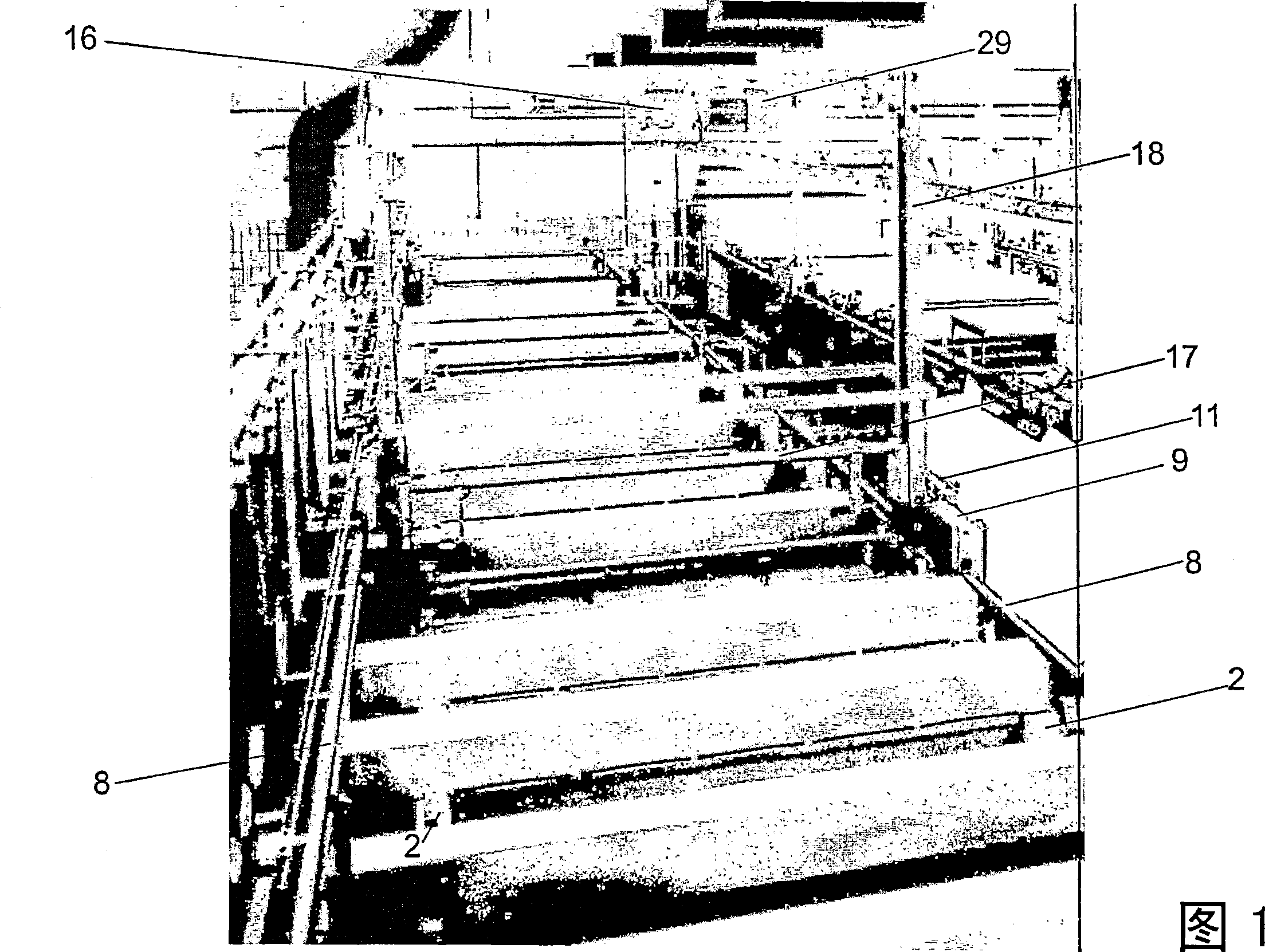

[0084] Figure 1 shows a prior art device for treating the surface of a workpiece. Devices of this type consist of a specific number of process tanks 2 arranged one behind the other to form a column of tanks. Transversely with the storage tank column, the track 8 is placed, and the transport vehicle frame 18 with the moving mechanism 9 driven by the transfer motor 11 moves on the track 8 from one processing storage tank to the next processing storage tank, and each transport vehicle frame has a A lifting mechanism 16 for moving the lifting beam 17 up and down of a transverse member. A flight bar (not shown) may be secured to a lifting beam with brackets to hold a workpiece or with clamps for directly securing a workpiece attached to the flight bar. A lift mechanism is used to lift the workpiece out of the processing tank and lower the workpiece into the processing tank, which is open towards the top end.

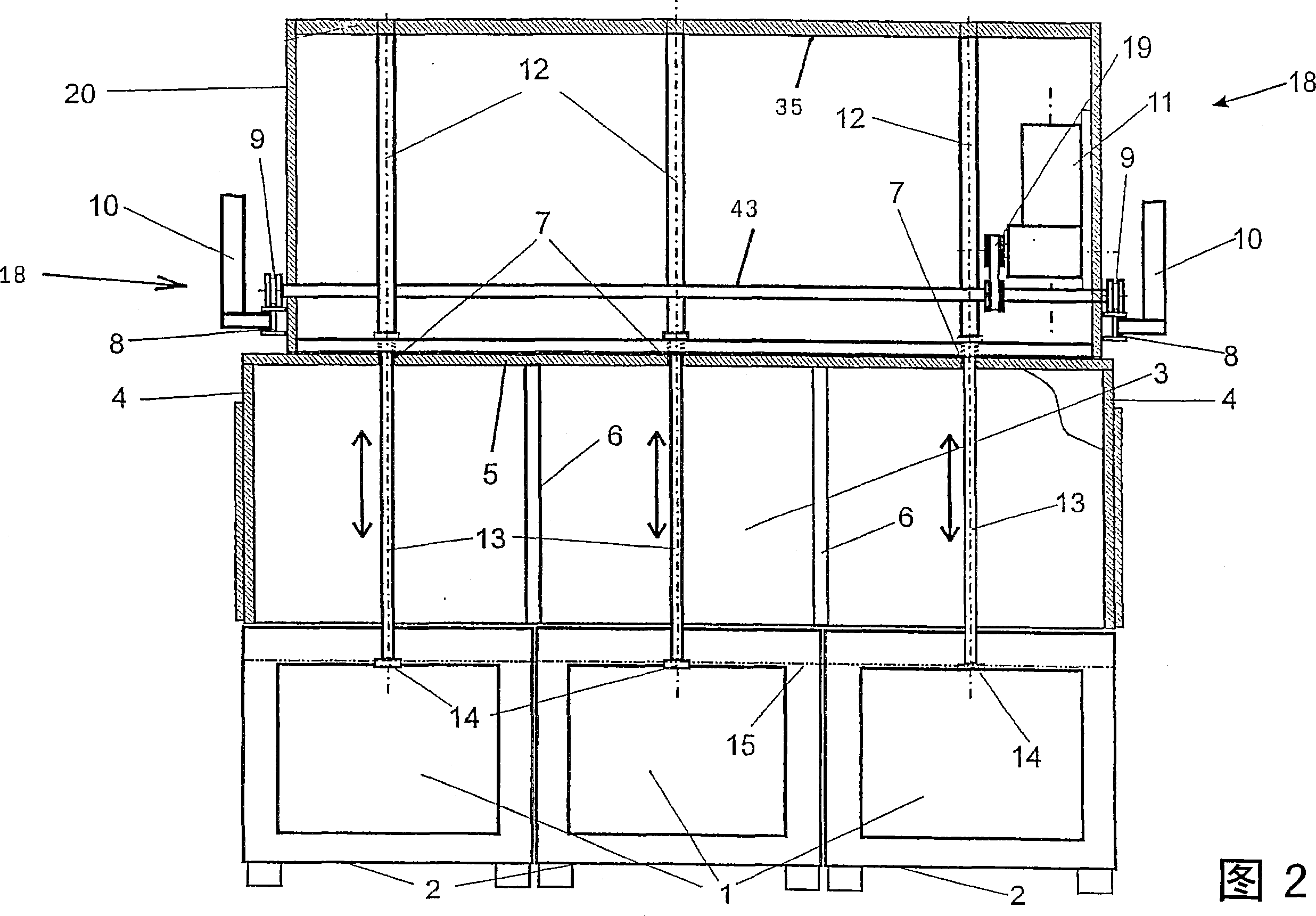

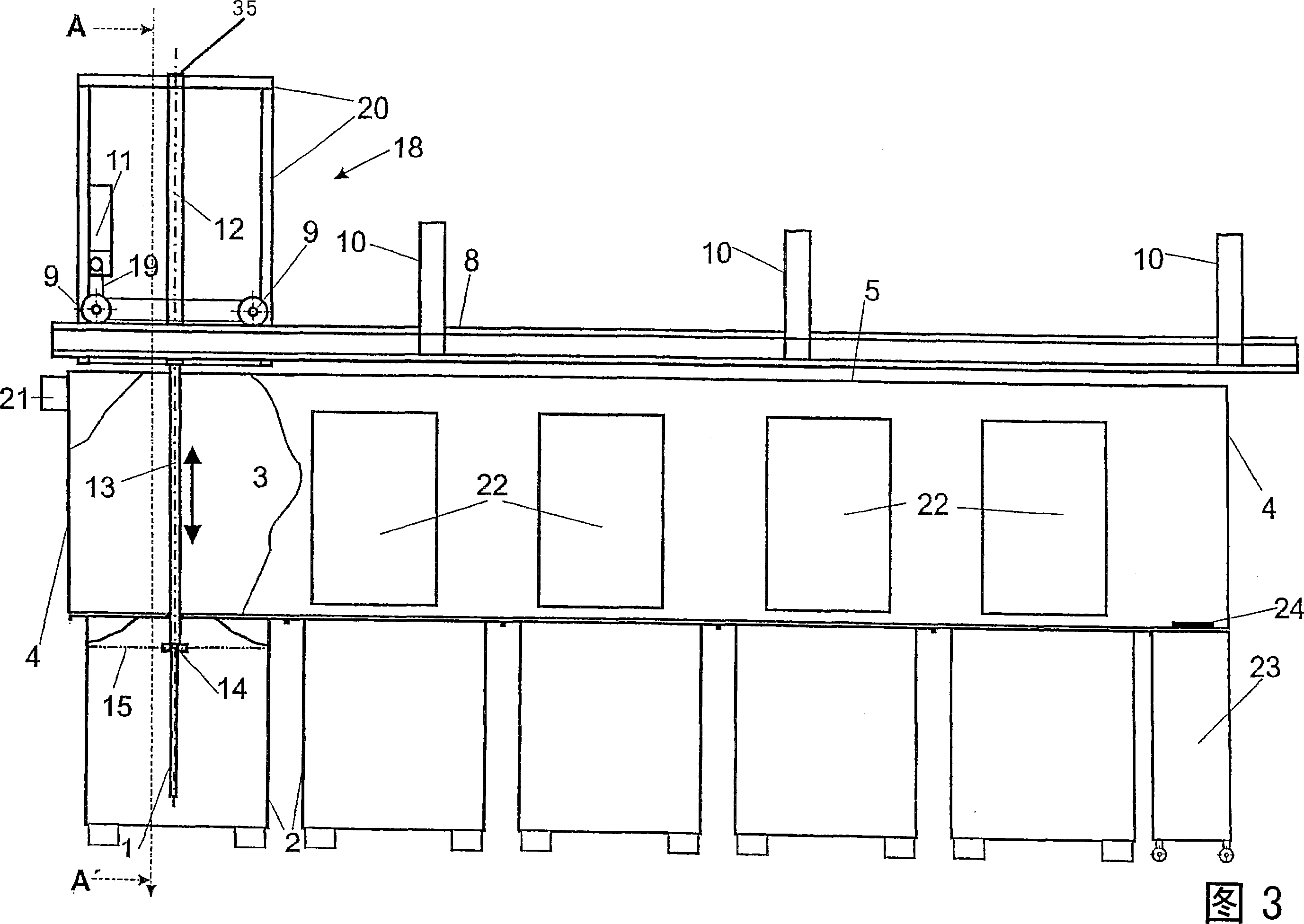

[0085] Figure 2 is a cross-sectional front view of a preferred embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com