Method and device for contactless treatment of flat objects in through type treatment equipment

A processing equipment and non-contact technology, which is applied in the field of non-contact processing of flat objects and devices in pass-through processing equipment, and can solve problems such as helplessness and pressure difference that cannot function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

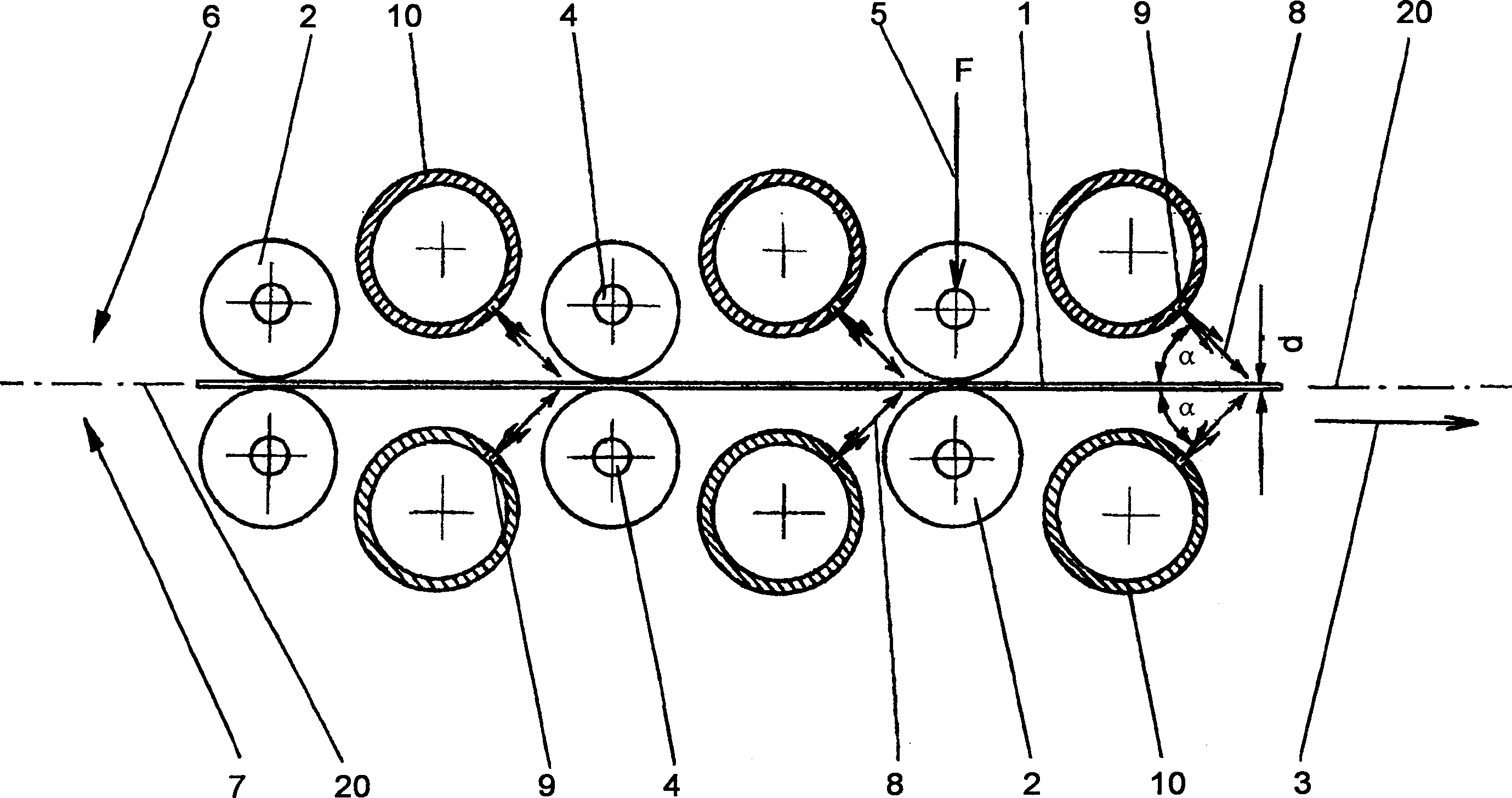

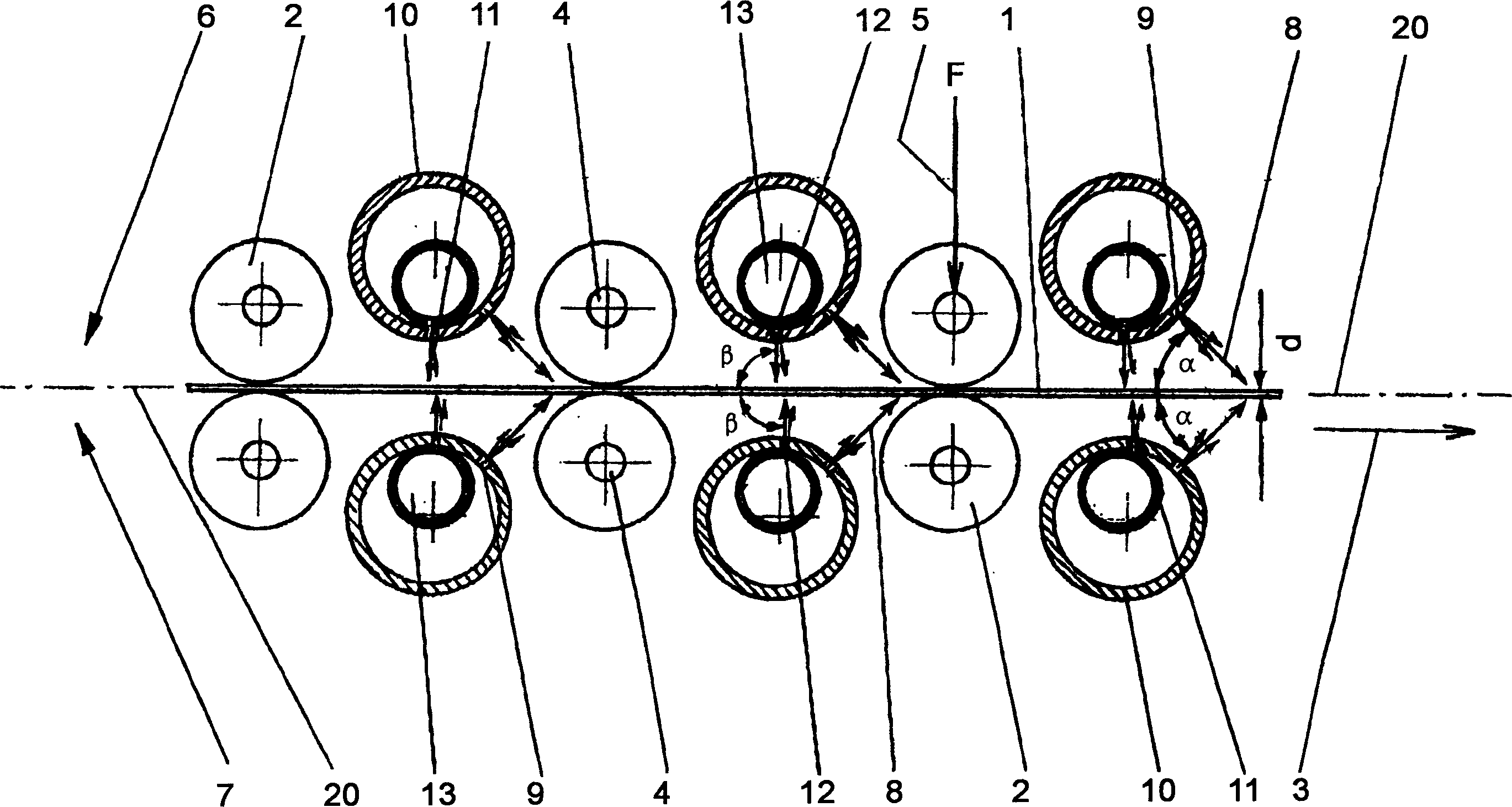

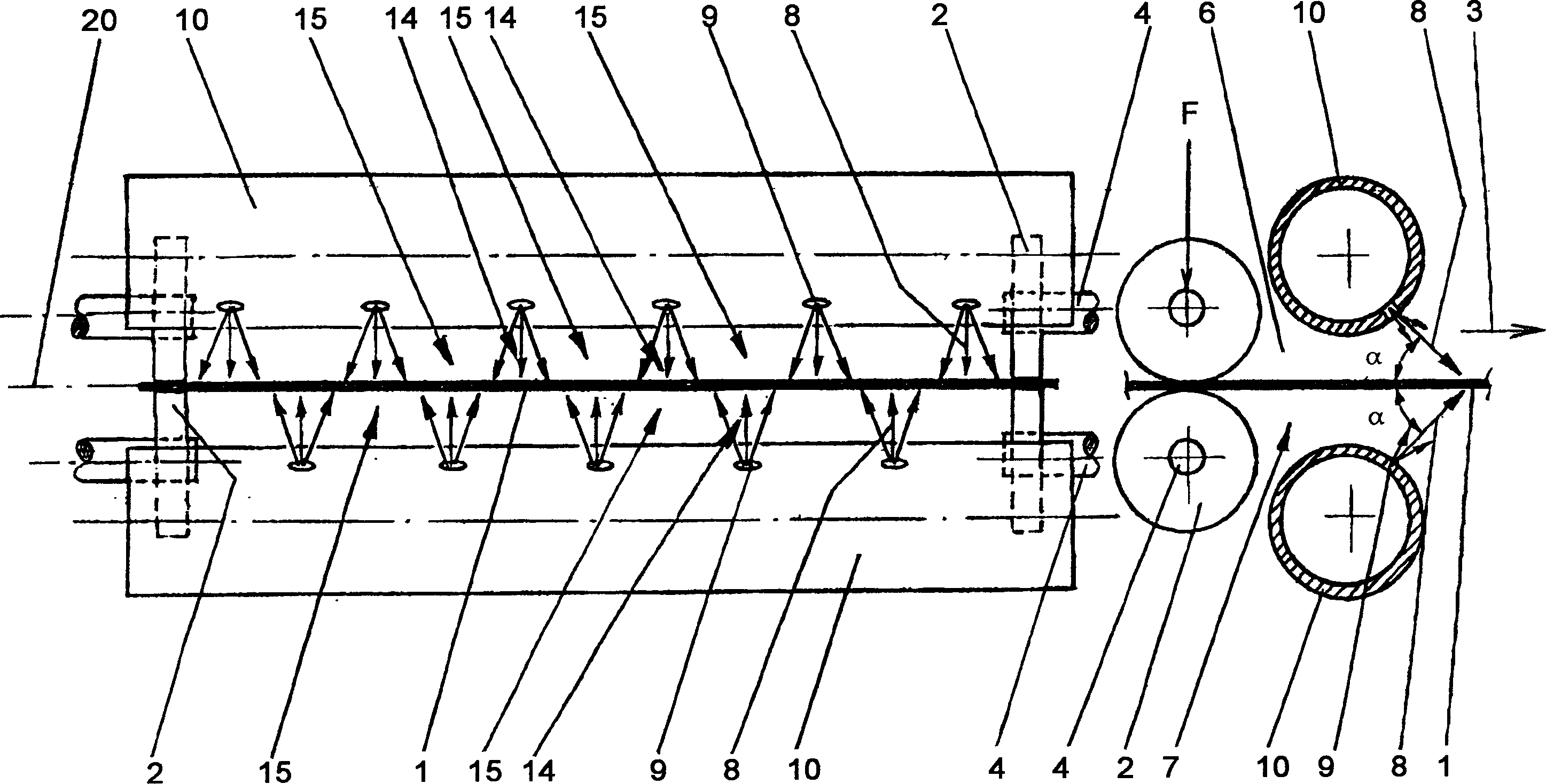

[0019] figure 1 In it, driven transport rollers 2 with axis 4 transport objects 1 to be processed in transport direction 3 . The transport rollers 2 grip the object 1 only at the two edges that do not belong to the effective area of the object. As a result, objects with more sensitive surfaces can also be produced. More and more thin and very thin objects are also treated wet-chemically and / or electrolytically. In circuit board technology, the thickness d of the conductive film is 50 μm or less. If the core of the circuit film is made of polyamide, for example, it can have a particularly high flexibility and be particularly sensitive on the surface. This makes conveying through wet chemical pass-through processing equipment significantly more difficult.

[0020] In circuit films of precision circuit technology, it is additionally required to maintain dimensional accuracy. The tensile force is only allowed to act on the circuit film to a limited extent. During transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com