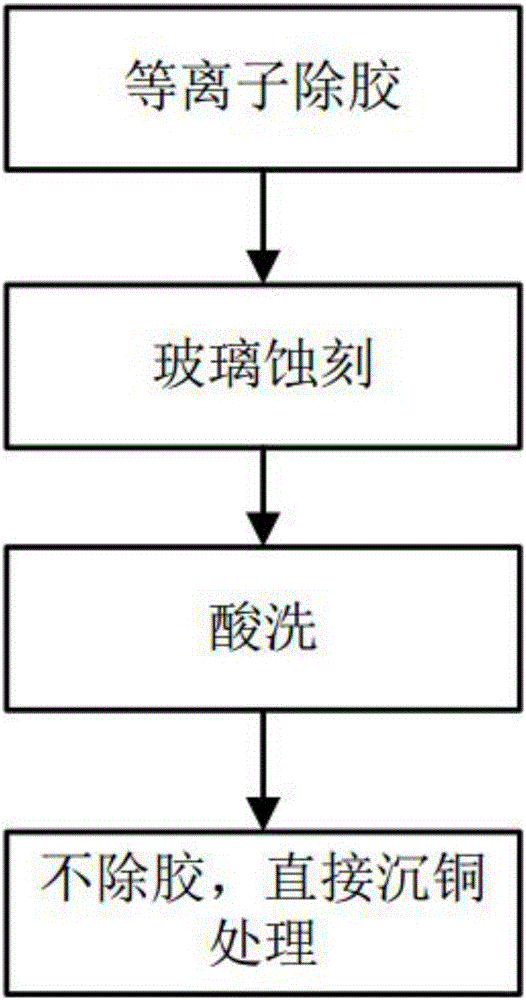

Multilayer PCB positive back etching process

A process and etching technology, which is applied in the field of PCB manufacturing, can solve the problems of unfavorable electrical connection reliability, unobvious etch performance, slow erosion rate, etc., and achieve the desired effect of etch etch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the process of plasma degumming in step S1, the mixed gas of nitrogen, oxygen and hydrogen tetrafluoride is ionized with the electrode power of 7500-8500W, so that it reacts with the hole wall of the PCB through hole; The etchback reaction occurs on the wall of the through hole.

[0035] In this embodiment, preferably, the electrode power is 8000W.

Embodiment 2

[0037] During the plasma degumming process in step S1, the gas flow rate of nitrogen is 145-175 sccm, the gas flow rate of oxygen is 1100-1300 sccm, the gas flow rate of carbon tetrafluoride is 215-265 sccm, and the reaction time is 14-16 min.

[0038] In this embodiment, preferably, after mixing 160 sccm of oxygen, 1200 sccm of oxygen, and 240 sccm of carbon tetrafluoride, the mixed gas is ionized, and the PCB is ionized and etched for 15 minutes.

Embodiment 3

[0040] During the plasma degumming process in step S1, the flow rate of argon gas is 2700-3300 sccm, and the reaction time is 27-33 minutes.

[0041] In this embodiment, preferably, 3000 sccm argon gas is ionized, and the PCB is ionized and etched for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com