Screen printing device

A technology of screen printing and printing position, which is applied in screen printing, screen printing machine, printing, etc., and can solve the problems of increasing waste, increasing the cost of screen templates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach

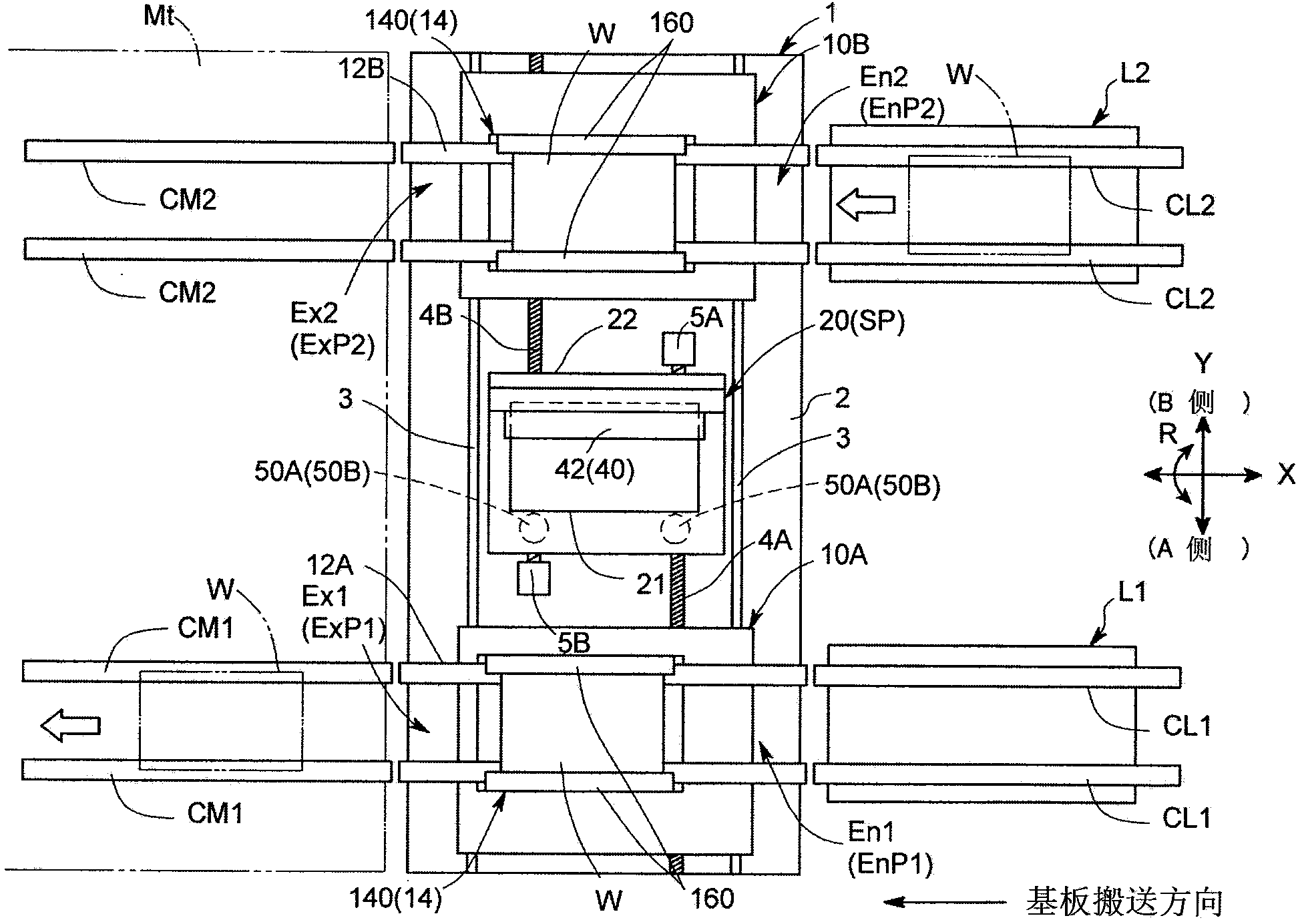

[0159] exist figure 1 In a general screen printing apparatus 1, for example, in the case of carrying out an out-and-out operation against a delay, if the common area is vainly deviated and the substrate support table 10B (10A) on the entry side is approached, the printing process is executed in the next process. The entry operation of the other substrate supporting table 10A ( 10B) may take time.

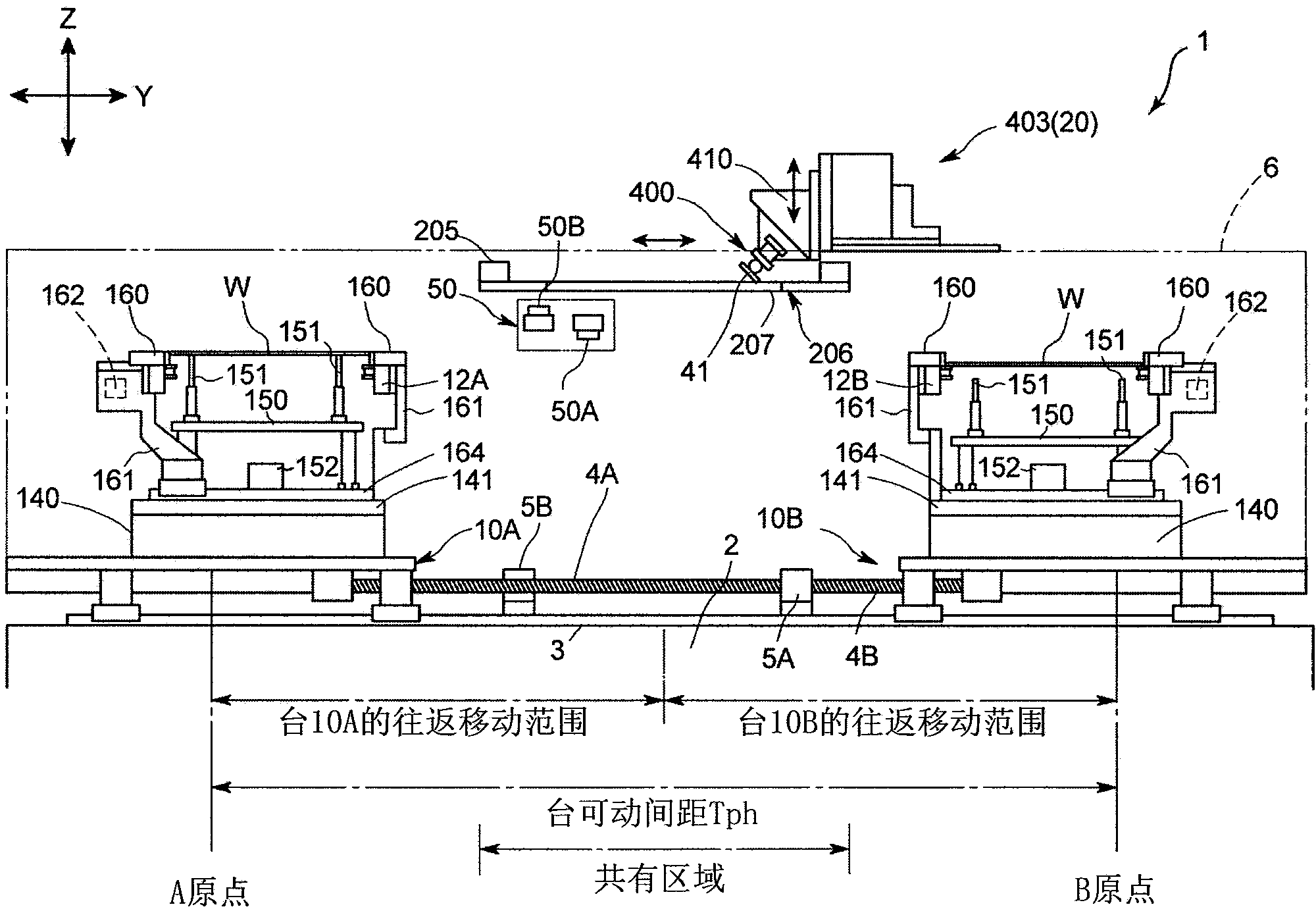

[0160] Therefore, in the third embodiment, as Figure 27 As shown, after performing the determination of the delay (step S105), calculate the time Tr (step S110) required for the substrate support table 10B that has moved into the action to enter the current printing position (step S110), and calculate the print execution unit 20 to the substrate support table. 10B moves the position Pr of Tr / 2 (step S111 ), and moves the substrate support table 10B and the print executing unit 20 to positions Pr, respectively.

[0161] If executed as Figure 27 In general processing, even if a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com