Environment-friendly novel circuit board manufacturing method

A manufacturing method and circuit board technology, which are applied in separation methods, printed circuit manufacturing, chemical instruments and methods, etc., can solve problems such as environmental damage, workshop air environment impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

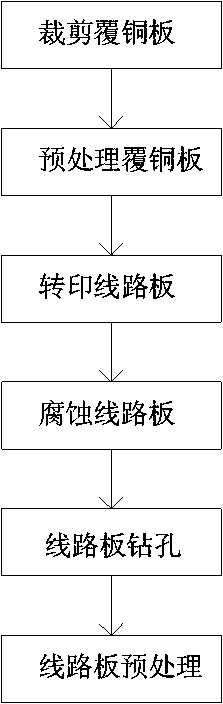

[0023] A kind of environmental protection novel circuit board manufacturing method, described evaluation method comprises the steps:

[0024] (1) Cut the copper clad laminate, and cut the copper clad laminate into the size of the circuit board according to the demand, not too large, so as to save materials and avoid material waste, and minimize the generation of leftover materials;

[0025] (2) Pretreat the copper clad laminate, and use fine sandpaper to polish off the oxide layer on the surface of the copper clad laminate, so as to ensure that the toner on the thermal transfer paper can be firmly printed on the copper clad laminate when the circuit board is transferred, and the polished The standard is that the surface of the board is bright and there are no obvious stains. When grinding, the dust generated by the grinding is sucked and filtered by the suction fan;

[0026] (3) Transfer the printed circuit board, put the copper clad laminate into the thermal transfer machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com