Post-deposition cleaning methods and formulations for substrates with cap layers

A technique for cleaning, substrates, applied to cladding, HIE, surfaces on metal and dielectric damascene metallization structures to the extent that they depart from the spirit and scope of the present invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

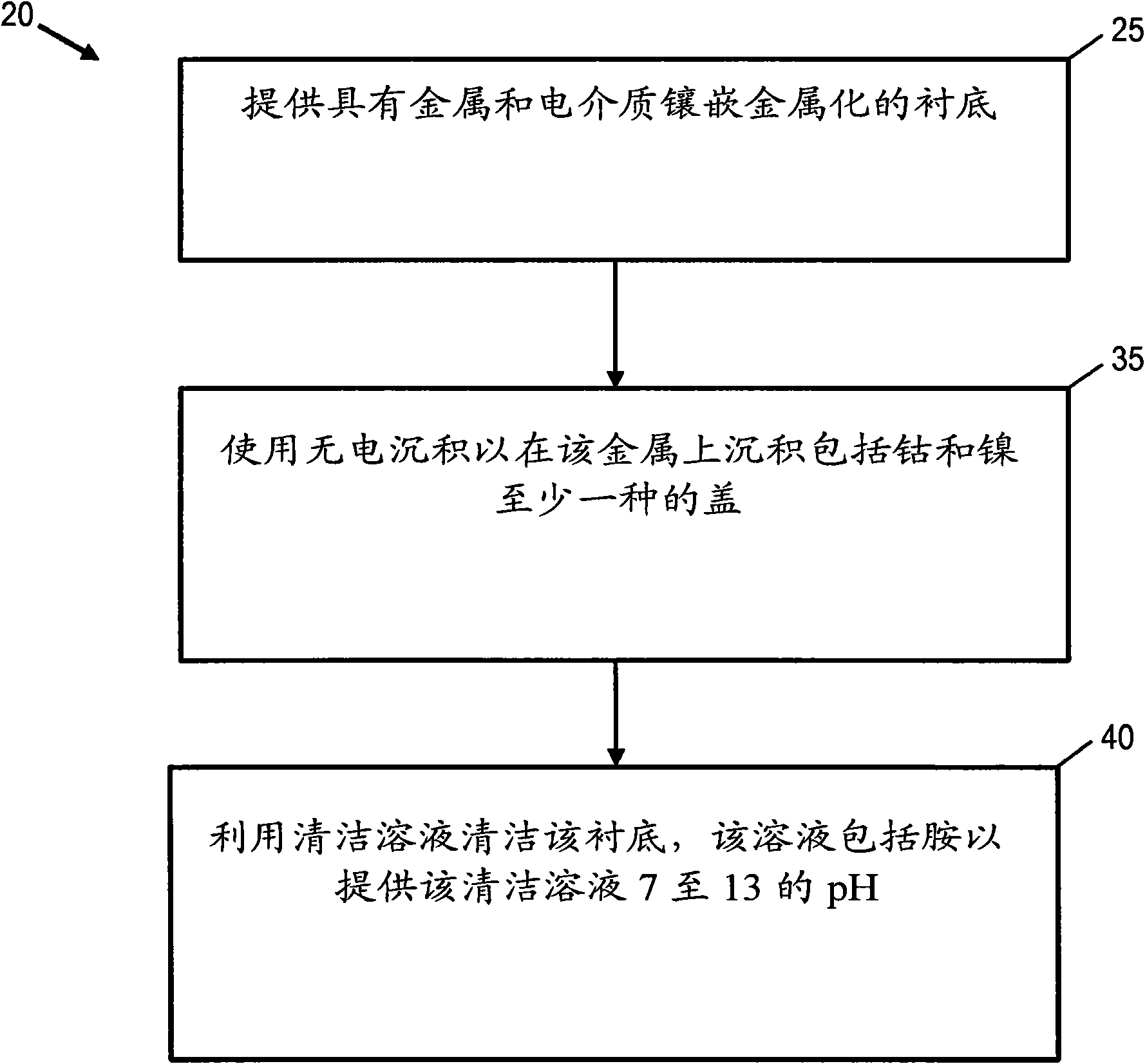

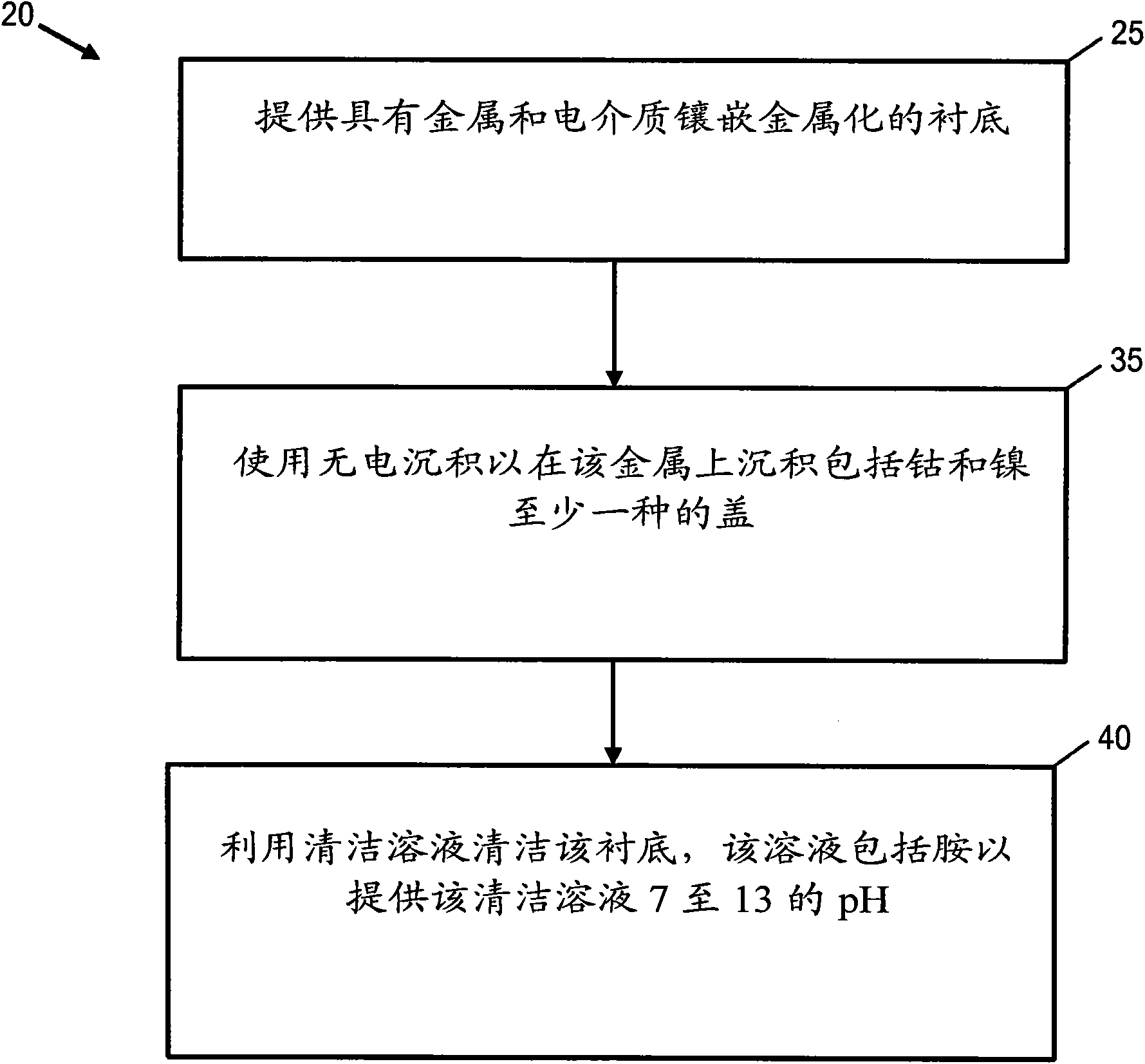

[0011] The present invention relates to interconnect metallization using a capped conductive metal and dielectric to form damascene metallization structures for electronic devices such as integrated circuits. More preferably, the present invention relates to an interconnect metallization layer for electronic devices comprising a dielectric and a metal (such as copper) with a cap comprising one of the chemical elements cobalt and nickel.

[0012] Operation of embodiments of the present invention will be discussed below, primarily in the context of processing semiconductor wafers, such as silicon wafers used in the manufacture of integrated circuits. The metallization layer for the integrated circuit comprises copper of metal lines, with an electrolessly deposited cap comprising at least one of the chemical elements cobalt and nickel or their alloys, formed as a damascene or dual damascene dielectric structure. Optionally, the dielectric is a low-k dielectric material, such as c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com