High-temperature high-pressure in-situ composite fretting test device

A fretting wear, in-situ composite technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems of difficulty in measuring friction pair friction, fretting wear, and electrochemical signals. High precision, simple control, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

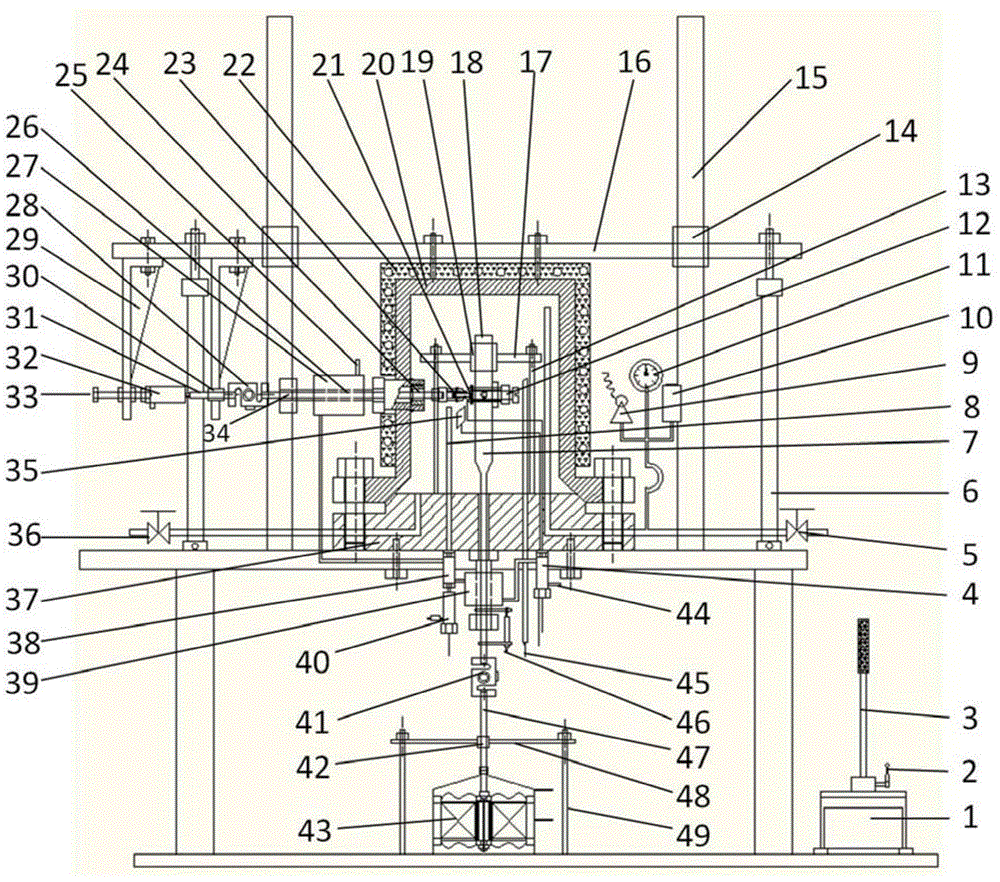

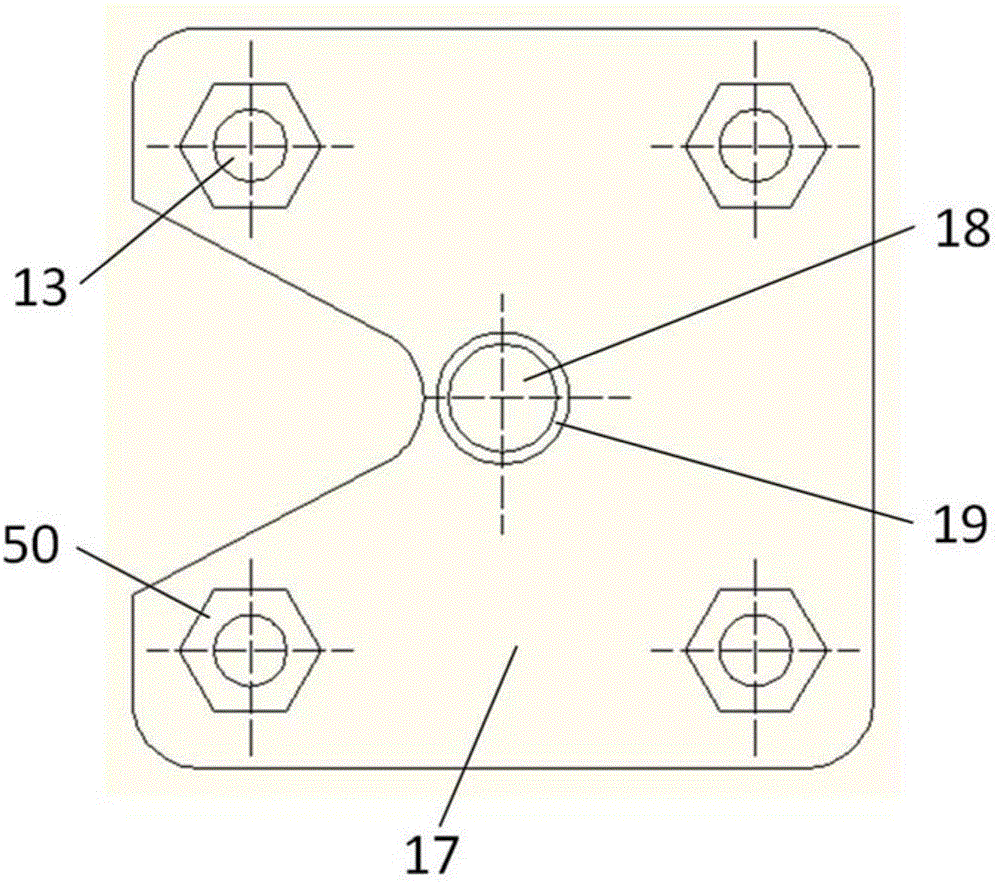

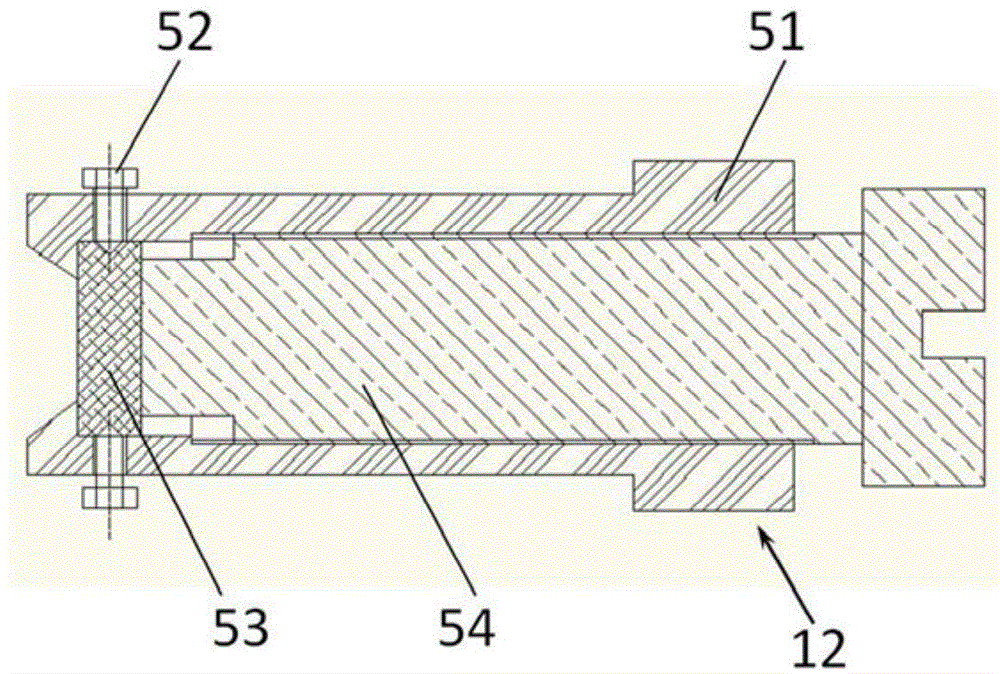

[0030] The high-temperature and high-pressure in-situ compound fretting wear test device of the present invention consists of a piezoelectric ceramic driver, a tension pressure sensor, an exciter, a displacement sensor, a linear guide rail, an autoclave body, an autoclave cover, a working electrode / auxiliary electrode seat, a reference Electrode seat, hydraulic cylinder, thermocouple, column, positioning plate, first sample clamping device, vertical motion axis, horizontal motion axis, motion axis guide bracket, auxiliary electrode, reference electrode, working electrode, guide platform plate, The guide rod and other components can realize in-situ tangential fretting wear, radial fretting wear and bidirectional (tangential and radial) compound fretting wear on the surface of the sample under high temperature and high pressure. In the present invention, the precise control of the radial constant load and alternating load of the sample is realized by installing the piezoelectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com