Hob complete utilization integrated gear hobbing method

A hobbing method and hob technology, applied in the direction of gear teeth, elements with teeth, belts/chains/gears, etc., can solve the problems of low hob utilization, increased hob axial movement, and short service life. , to achieve the effect of improving work stability and accuracy, overcoming tooth profile errors, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

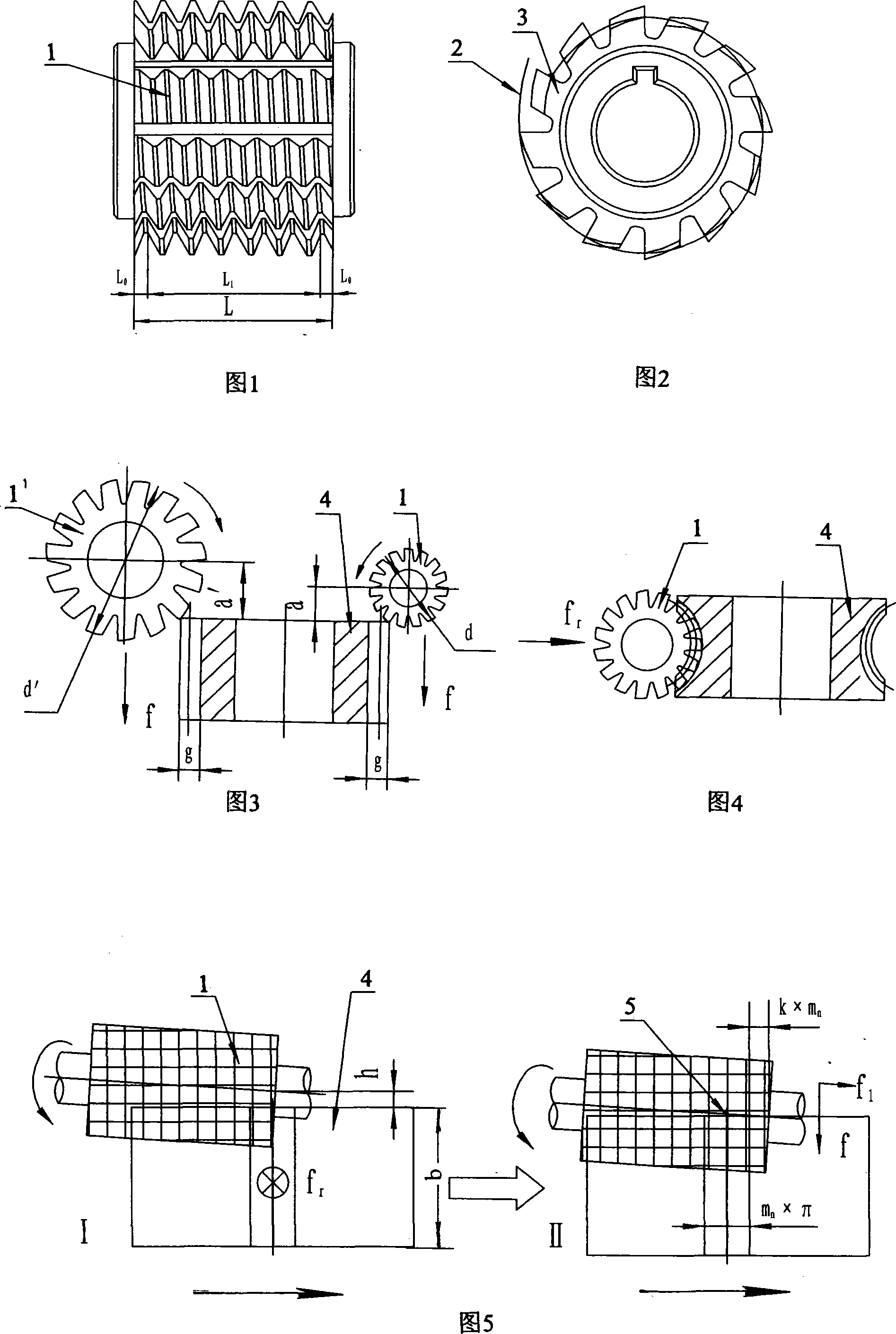

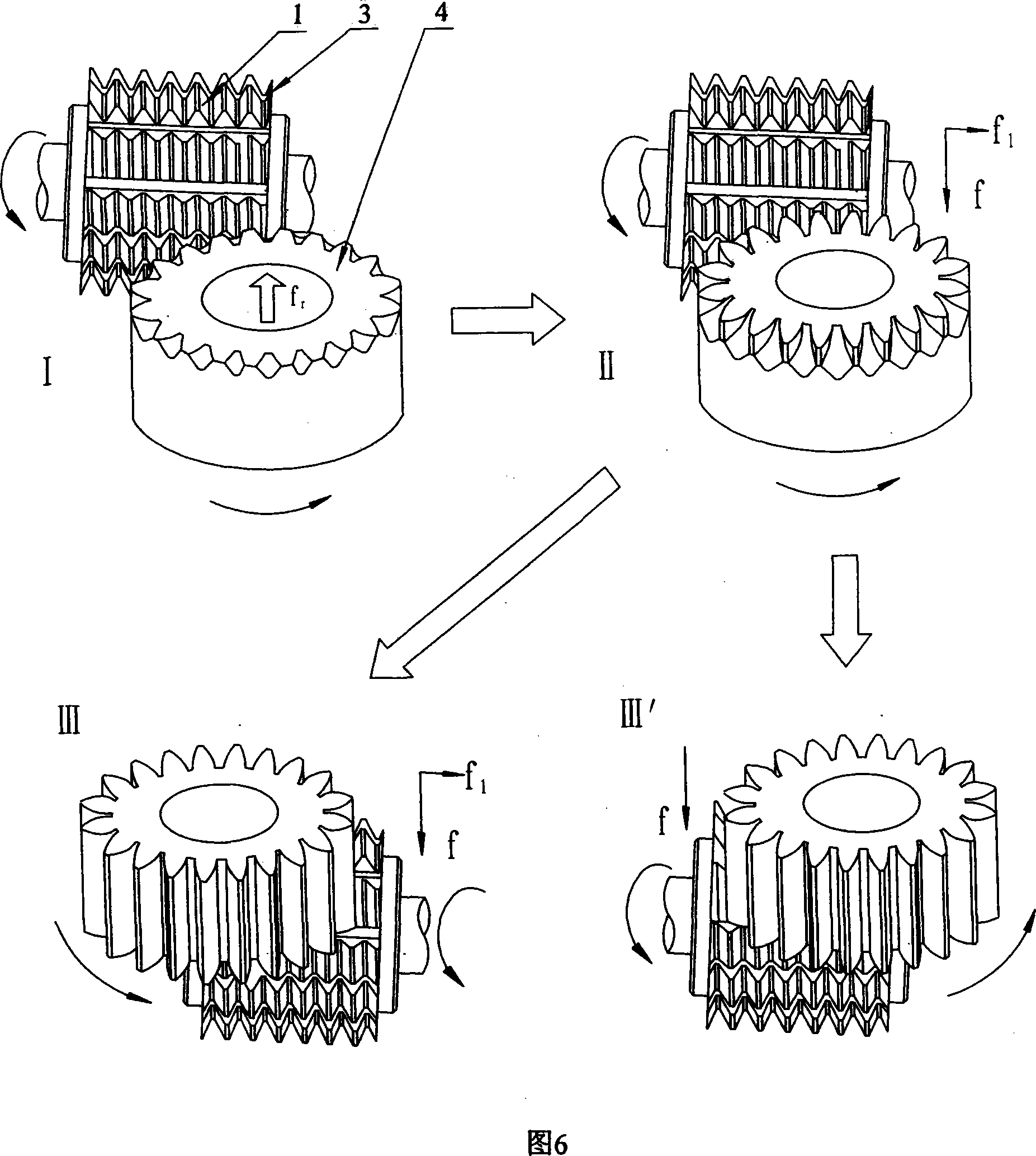

[0049] Processing-normal modulus m n =2mm, number of teeth Z=20, tooth width b=30mm, depth of cut g=4.5 spur gear.

[0050] Hob outer diameter d=100mm, number of hob heads Z0=1

[0051] Processing technology: hob speed n=400 rpm, safety factor k=0.2

[0052] Axial feed f=0.66 mm / rev

[0053] Tangential feed f 1 =0.22mm / rotation

[0054] Radial feed f r =1.2mm / rotation

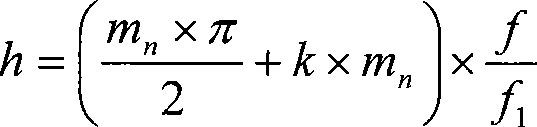

[0055] Reel Elevation:

[0056]

[0057] Hobbing time:

[0058] = zg nf r z 0 + z ( h + b ) nfz 0 = 20 × 4.5 400 × 1.2 × ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com