Test method and device for monitoring steel wire fretting fatigue state

A technology of fretting fatigue and test method, which is applied in the direction of testing wear resistance and using stable tension/pressure to test the strength of materials, etc. It can solve the problems that the failure mechanism of steel wire fretting fatigue cannot be studied, and achieves wide practicability and effect Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

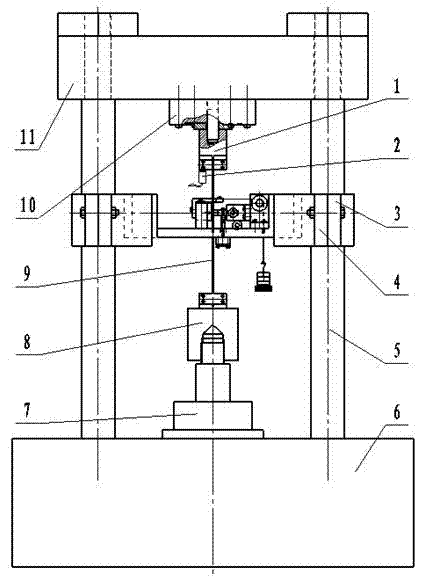

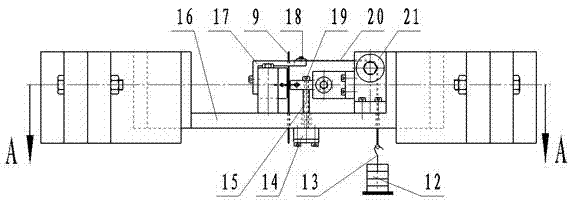

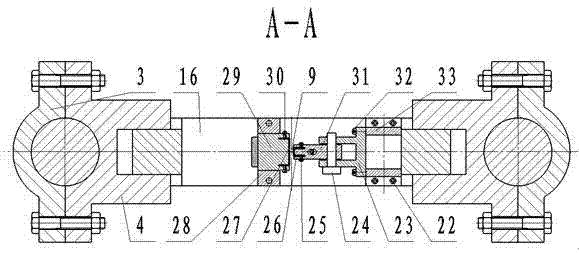

[0017] The test method for monitoring the fretting fatigue state of the steel wire of the present invention: first, one end of the test steel wire 9 is fixed on the upper clamping block 1, and the concave horizontal support 16 is adjusted so that the test steel wire 9 vertically passes through the L-shaped connecting frame 17 respectively. and the round hole of the concave horizontal support 16, the lower end of the test steel wire 9 is fixed on the lower clamping block 8, and then the hydraulic lifting platform 7 is started by the computer-controlled electro-hydraulic servo hydraulic system to stretch the test steel wire 9 downward, so that the test The steel wire 9 is gradually straightened, and when the tensile force borne by the test steel wire 9 reaches the set initial load, the operation of the hydraulic lifting platform 7 is stopped. Adjust the conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com