Point contact type fretting fatigue test device and point contact type fretting fatigue test method

A technology of fretting fatigue and test equipment, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unadhesive area, slip area and open area research, difficulties in applying tribological theory, and in-depth research on fretting fatigue theory Constraints and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The fatigue testing machine mentioned in this embodiment is the MTS809 electro-hydraulic servo testing machine.

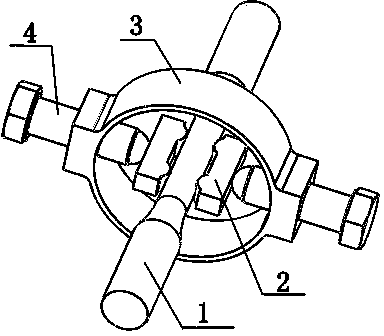

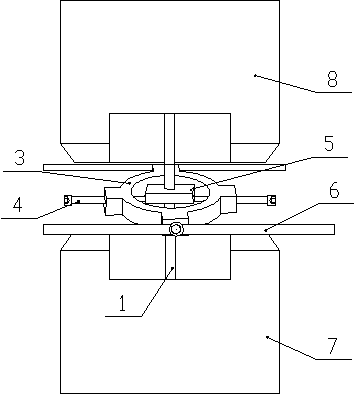

[0031] Such as figure 1 , figure 2 As shown, a point contact fretting fatigue test device includes a fretting bridge 2 in direct contact with the sample 1, a loading ring 3 whose ring surface is perpendicular to the axial direction of the sample 1, passes through the ring wall of the loading ring and fretting The loading bolt 4 contacted by the bridge 2, and the assembly frame 5 arranged in the loading ring 3, the sample 1 passes through the center of the annulus of the loading ring 3, and the contact surface between the fretting bridge 2 and the sample 1 is set There are convex arc-shaped fretting bridge feet, and the loading ring 3 is provided with strain gauges and connected with strain gauges.

[0032] Such as Figure 6 , Figure 7 As shown, a symmetrical side of the assembly frame 5 is hollowed through, and the hollow through cavity is used to pla...

Embodiment 2

[0044] The fatigue testing machine mentioned in this embodiment is the MTS809 electro-hydraulic servo testing machine.

[0045] Such as figure 1 , figure 2 As shown, a point contact fretting fatigue test device includes a fretting bridge 2 in direct contact with the sample 1, a loading ring 3 whose ring surface is perpendicular to the axial direction of the sample 1, passes through the ring wall of the loading ring and fretting The loading bolt 4 contacted by the bridge 2, and the assembly frame 5 arranged in the loading ring 3, the sample 1 passes through the center of the annulus of the loading ring 3, and the contact surface between the fretting bridge 2 and the sample 1 is set There is a convex arc-shaped fretting bridge foot, and the loading bolt 4 is provided with a strain gauge and is connected with a strain gauge.

[0046] Such as Figure 6 , Figure 7 As shown, a symmetrical side of the assembly frame 5 is hollowed through, and the hollow through cavity is used ...

Embodiment 3

[0057] In this embodiment, the structure of the point contact fretting fatigue test device is the same as that in Embodiment 2.

[0058] Such as Figure 8 As shown, in this embodiment, the sample is LZ50 axle steel, and the fretting fatigue test under circular path loading is carried out on the MTS809 type tension-torsion combined electro-hydraulic servo material testing machine with a point-contact fretting fatigue test device added. The pull-down torsional compound fretting in the circular path is carried out under the control load mode in the axial and torsional directions, and the axial stress amplitudes of 300Mpa, 400Mpa, 450Mpa and 500Mpa are respectively applied to the sample, 173MPa, 231MPa, 260MPa and 289MPa The torsional stress amplitude, the contact pressure is controlled and kept constant by loading bolts and strain gauges, the axial and torsional frequencies are 1Hz, the ratio of axial and torsional stress is r=0.1, the loading waveform is sine wave, and the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com