Solid laser and heat-dissipating device thereof

A technology of solid-state lasers and laser devices, which is applied to laser components, lasers, phonon exciters, etc., can solve the problem of low cooling efficiency of laser devices, achieve improved cooling efficiency, small contact area, and thermal isolation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

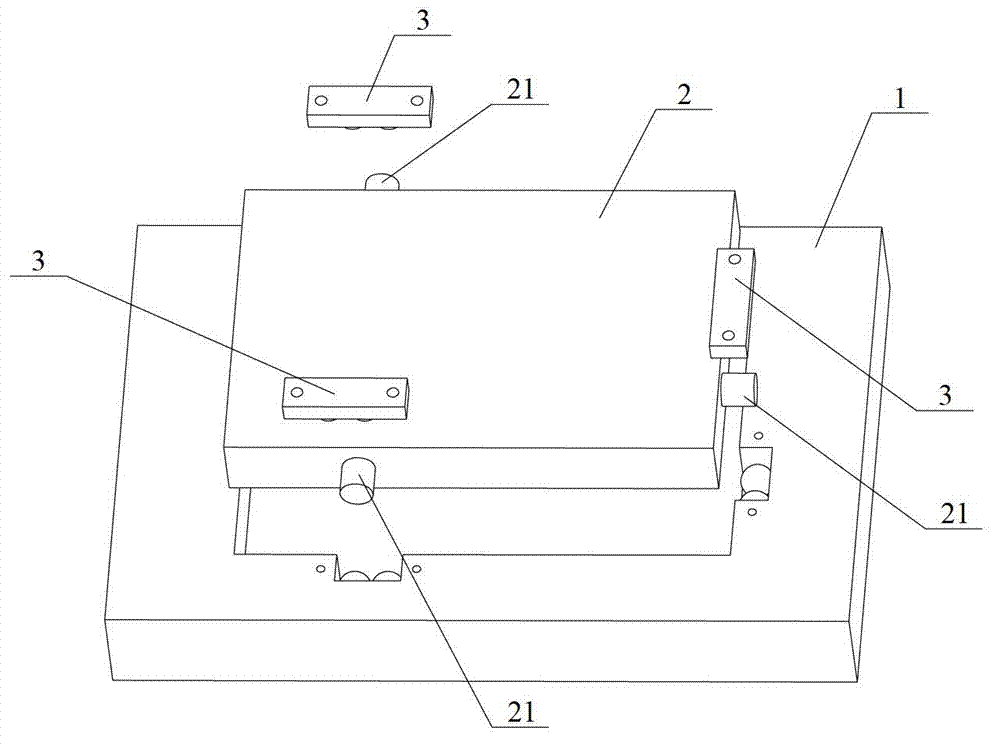

[0022] Such as figure 1 As shown, the solid-state laser and its laser device heat dissipation device provided by the present invention include a support base 1 , a mounting plate 2 and a plurality of pressing blocks 3 . The mounting plate 2 is used to install the laser device. The function of the support base 1 is to support the mounting plate 2 and realize the connection with other components of the solid-state laser. The function of the pressure block 3 is to fix the mounting plate 2 on the top surface of the support base 1 .

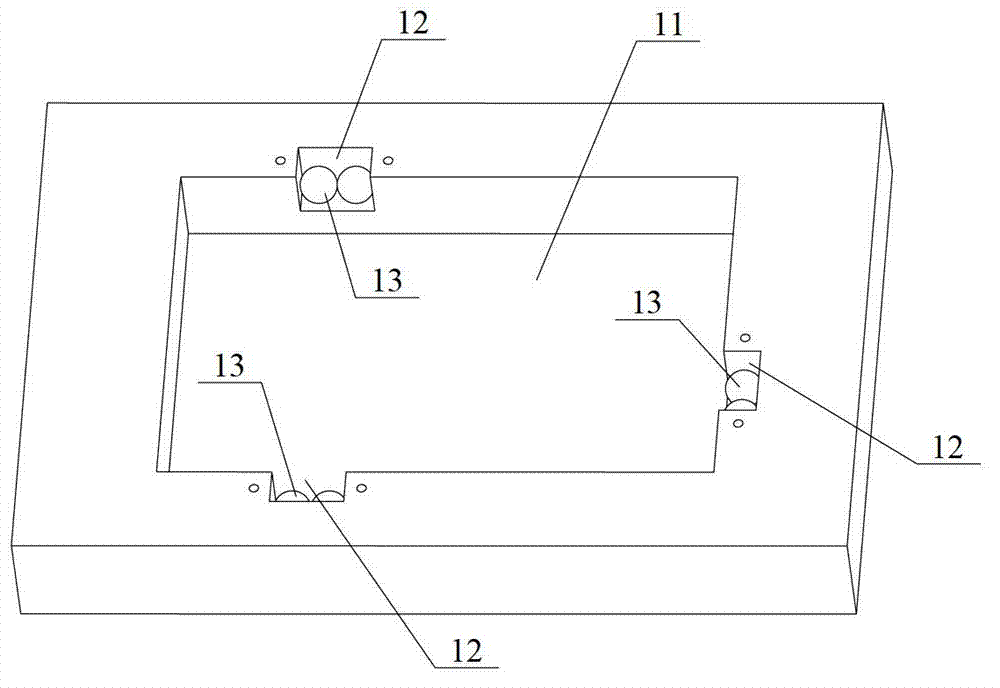

[0023] see you again figure 2 There is a pit 11 on the top surface of the support seat 1, and three grooves 12 are arranged on the inner side wall of the pit 11, each groove 12 communicates with the top surface of the support seat 1, and each groove 12 Two first steel balls 13 are respectively placed, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com