No-twist compound pendulum consisting of oscillating bar and cylindrical pendant in ring connection

A pendant and ring technology, applied in the field of non-twist compound pendulum production, can solve the problems of knife-edge damage to the hanging rod, long time, poor durability of the hanging rod and the pendulum rod, etc., to avoid twisting, improve durability, improve The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

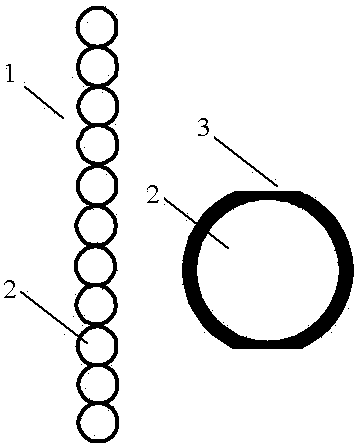

[0009] The swing rod 1 of the compound pendulum is composed of 99 metal rings 2 with a diameter of 1.2cm. The metal rings are symmetrically cut to a thickness of 1mm, so that the distance between the two cut surfaces 3 is 1cm. The metal rings are made of stainless steel or high hardness Aluminum alloy metal wire, the cross section of the metal wire is a circle with a diameter of 2mm. In order to ensure the symmetry of the swing bar, 99 rings are clamped with card slots to ensure that all rings are in close contact and all contact points are connected. The lines pass through the center of each ring, and then use the double-sided spot welding process to weld all the contact points of the rings.

[0010] The pendant of the compound pendulum is a stainless steel or high-hardness aluminum alloy cylinder with a diameter of 3-4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com