Friction wear testing machine for on-line measurement

A friction and wear test, friction and wear technology, applied in the direction of measuring devices, testing wear resistance, using mechanical devices, etc., can solve the problems of inconvenient material wear changes, inability to measure surface morphology and wear amount online, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

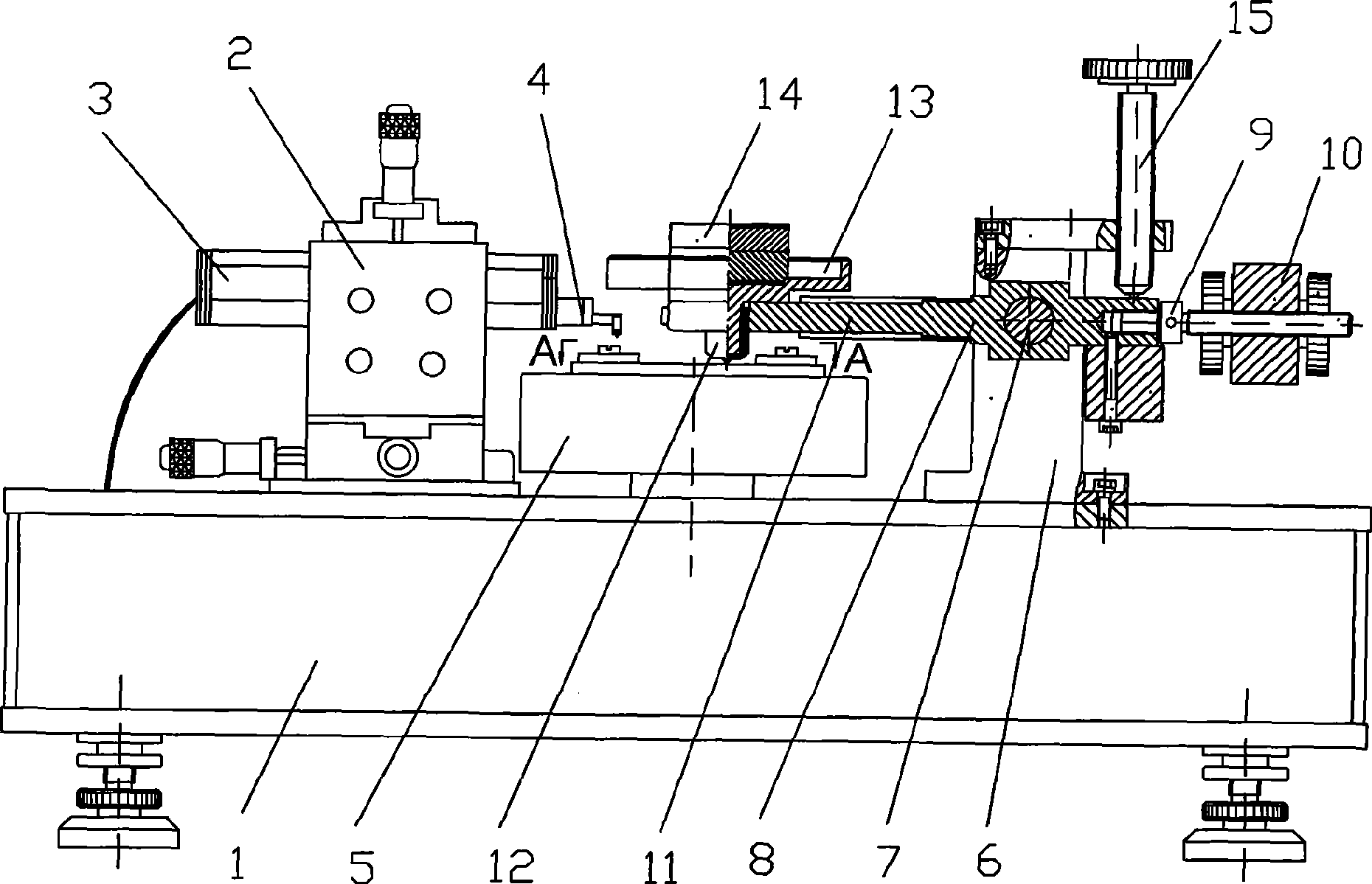

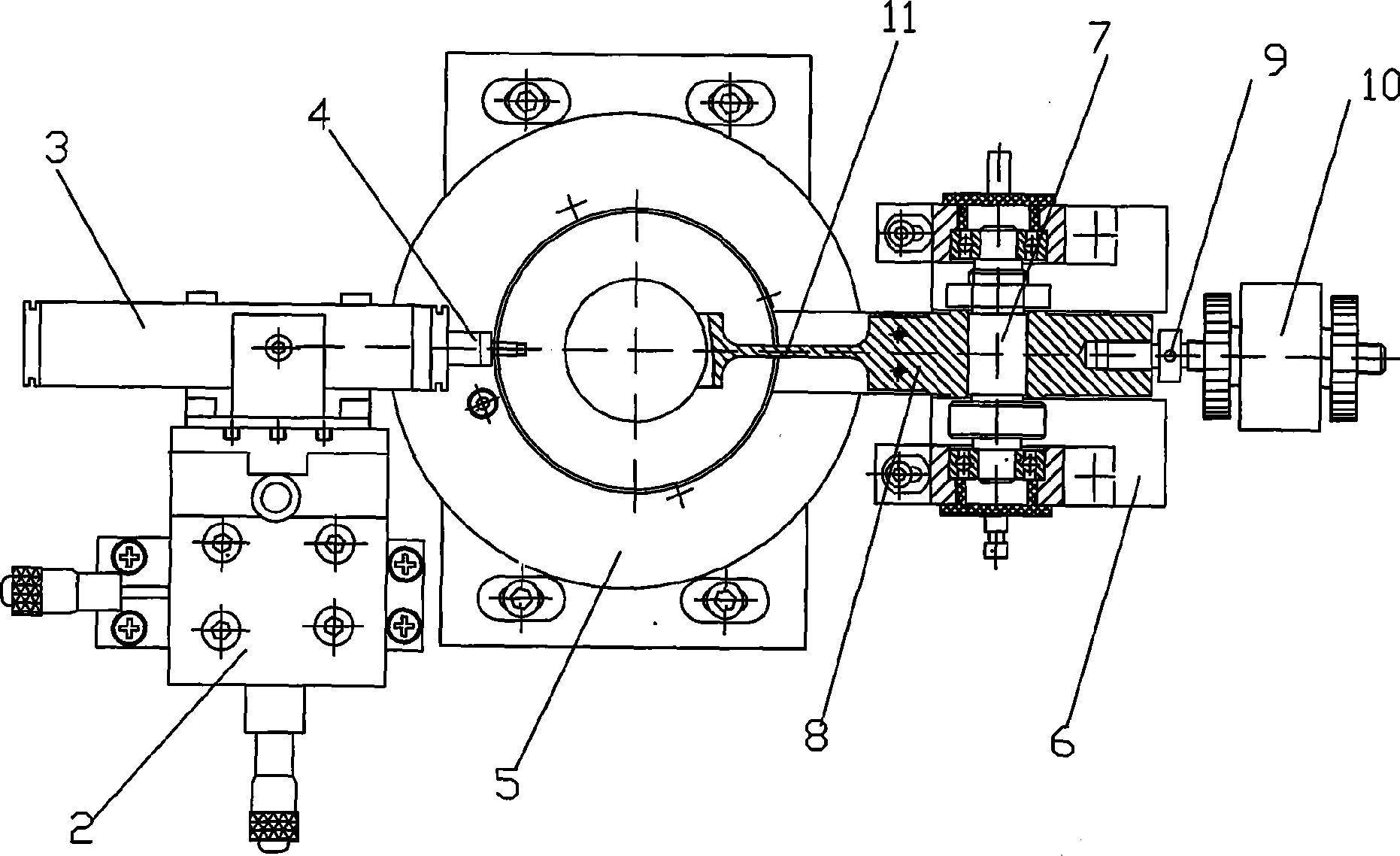

[0022] refer to figure 1 , figure 2 , the on-line measurement friction and wear testing machine of the present invention mainly includes: a test bench 1, a friction and wear test device and a surface topography measuring device arranged on the test bench 1.

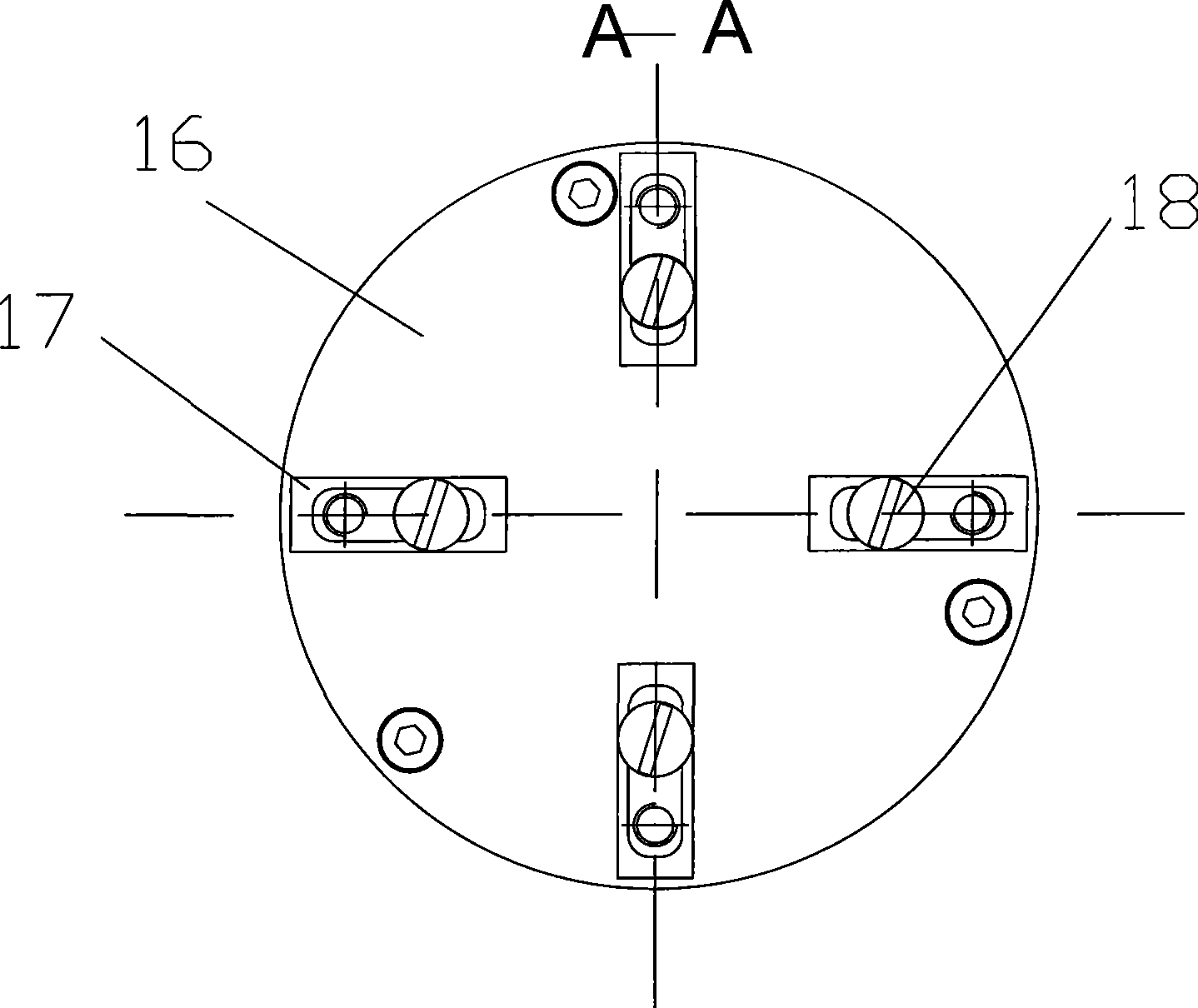

[0023] In the friction and wear experimental device, a support 6 and a rotating platform 5 are arranged on the test bench 1, the support 6 is located on the right side of the rotating platform 5, and the rotating platform 5 is driven by a motor. combine image 3 As shown, the lower test piece tray 16 is fixed on the rotary platform 5, and four spacers 17 are symmetrically arranged on the lower test piece tray 16, and a bar-shaped hole is arranged in the middle of the spacer 17, and a locking screw 18 is arranged in the bar-shaped hole. The test piece is fixed on the lower test piece tray 16 by four locking screws 18 . The two ends of the rotating shaft 7 are connected to the support 6 through bearings, the swing beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com