Rubber abrasion test equipment

A testing equipment and rubber technology, which is used in testing the wear performance of rubber under different environmental conditions. In the field of rubber wear test equipment, it can solve the problems that it is difficult to reflect the wear resistance of tread rubber and single test conditions, so as to facilitate continuous batch testing. , test efficiency is improved, promotion and application prospects are good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described by the following embodiments in conjunction with the accompanying drawings:

[0017] The rubber abrasion testing equipment provided by the invention is realized through the following key technologies:

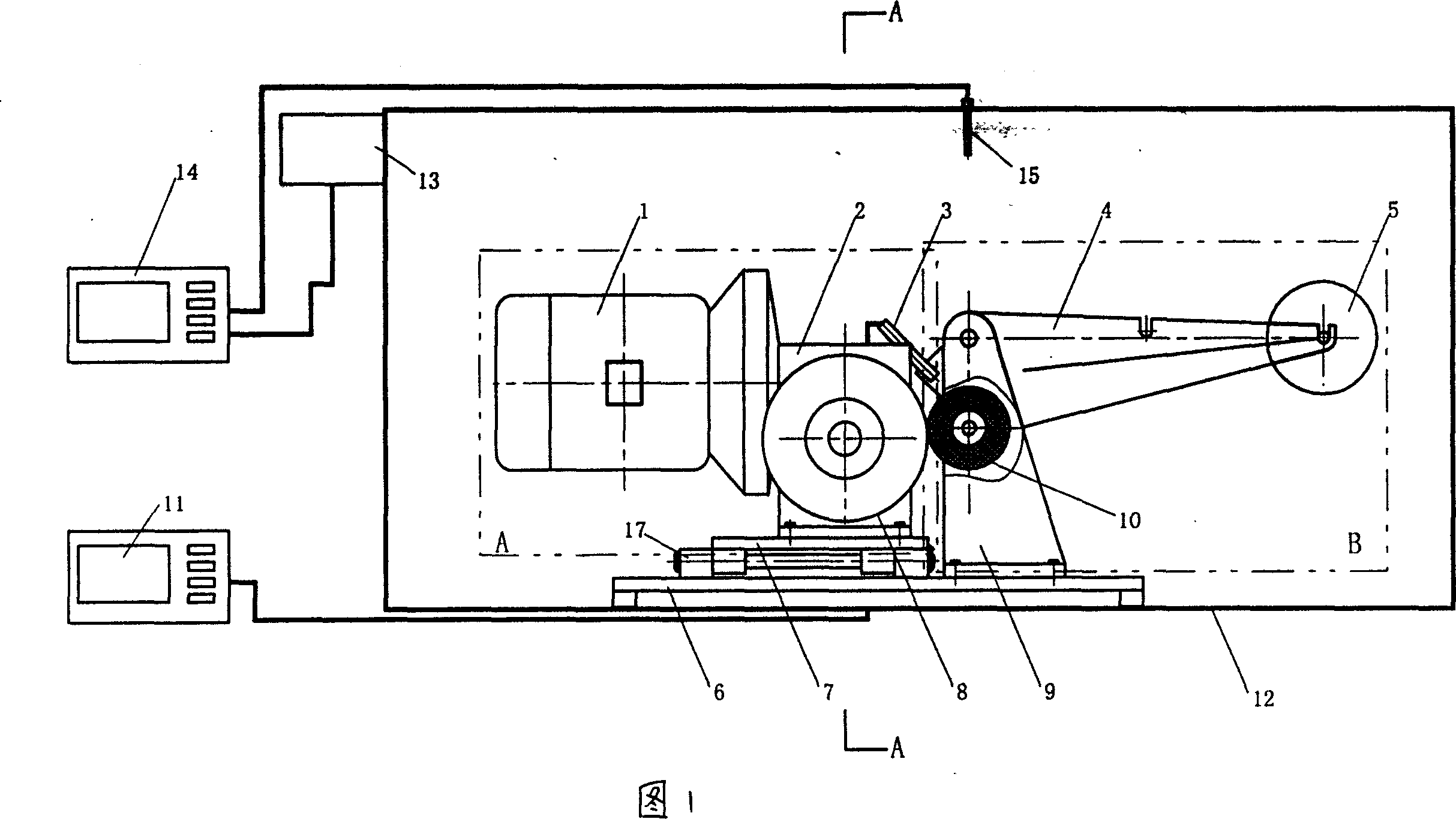

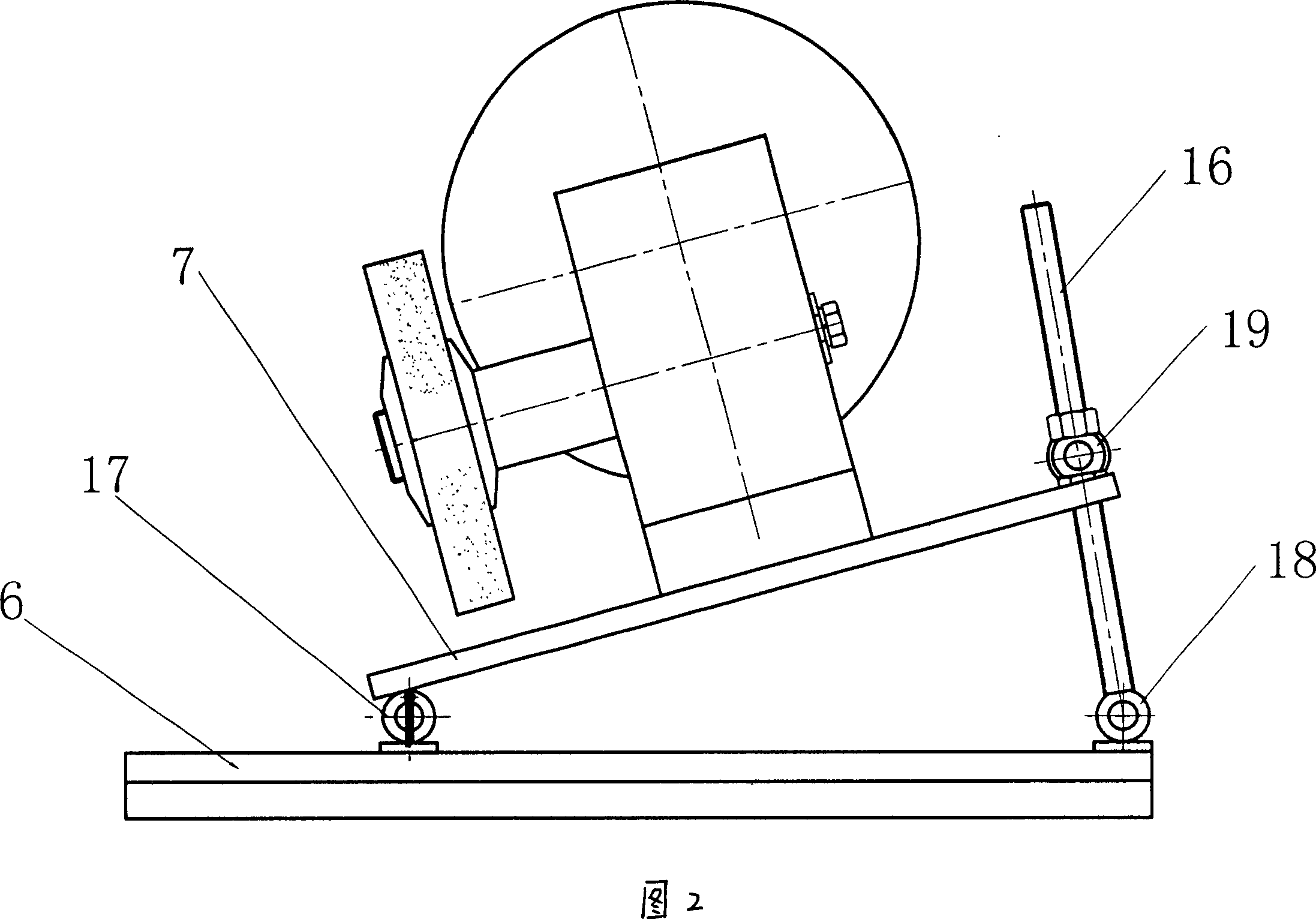

[0018] As shown in Figure 1, the rubber wear test equipment is composed of the main body of the wear machine, the temperature adjustment device, the speed control device, the angle adjustment device and the temperature measurement device; the main body of the wear machine is divided into a driving system A and a driven system B, The driving system A includes an adjustable speed motor 1 , a speed controller 2 , and a grinding wheel 8 , and the driven system B includes a loading lever 4 , a weight 5 , a bracket 9 and a sample rubber wheel 10 . The driving system A is assembled on the motor base 7, and the driven system B is directly installed on the base 6 through bolts. In order to meet the requirements of testing under dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com