A continuous test method for abrasion of short fiber radially oriented tread rubber

A testing method and tread rubber technology, applied in the direction of testing wear resistance, etc., can solve the problems of high maintenance cost, great influence of wear volume, troublesome sample preparation, etc., and achieve the effect of high testing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

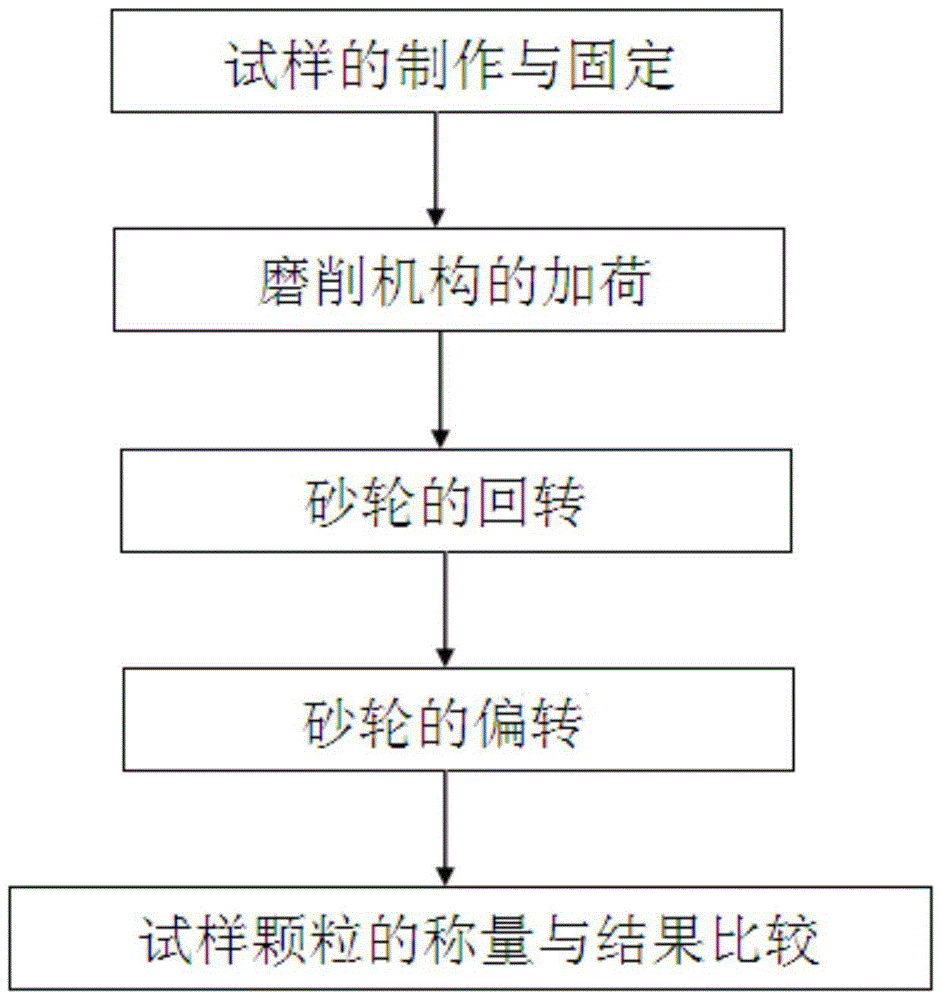

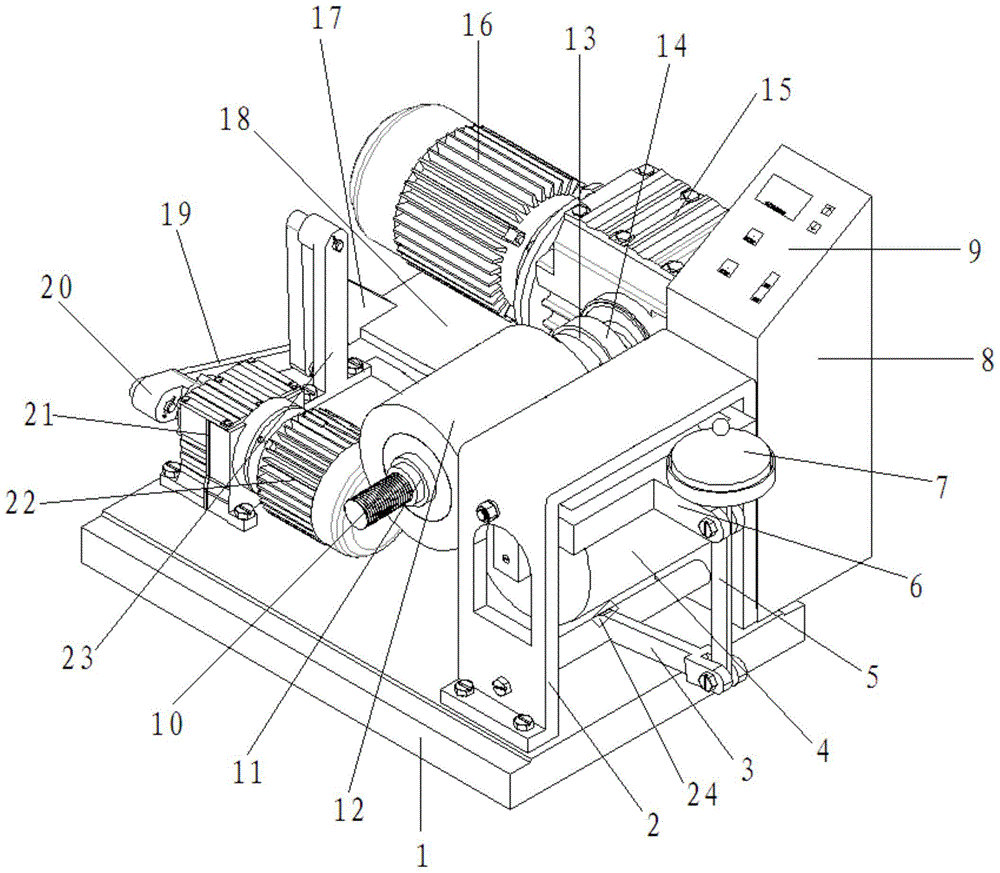

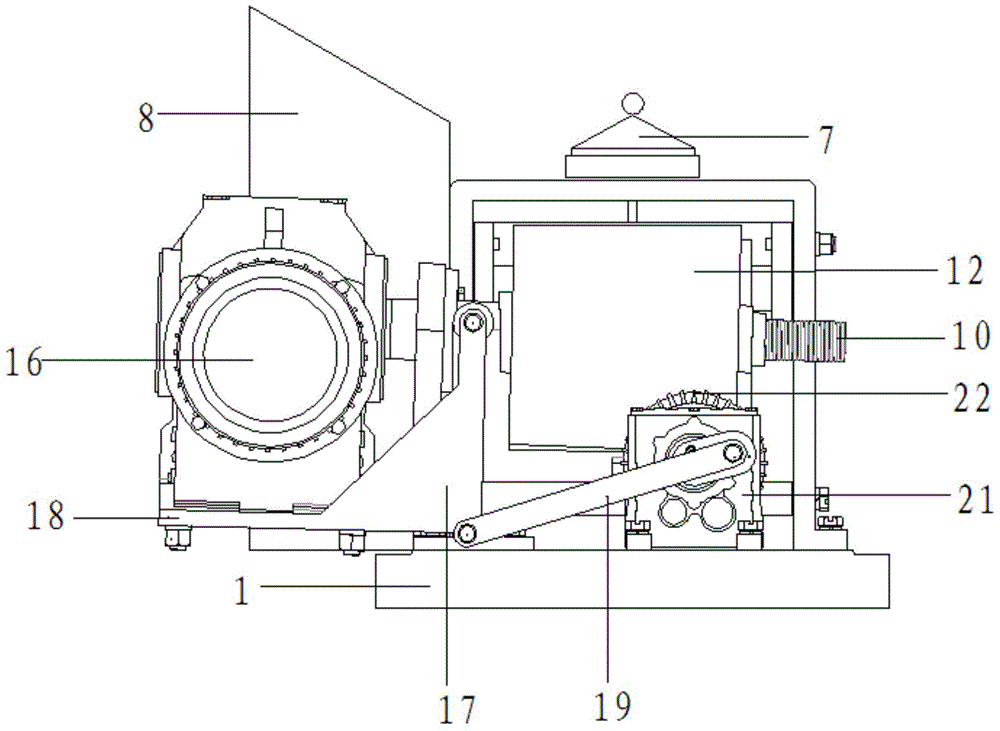

[0026] The short fiber radially oriented tread rubber abrasion test method involved in this embodiment specifically includes the following steps:

[0027] (1) Preparation and fixation of the sample: The vulcanized short fiber radially oriented tread rubber (hereinafter referred to as the sample) is bent into a tire shape and glued to the rubber wheel 4. Note that it should not be under tension during bonding. The designed length of the sample cannot completely cover the rubber wheel 4 and there is a notch. The method of fixing the sample with the Akron abrasion tester in the prior art is used to fill the notch with a sticky rubber strip so that the sample is completely wrapped On the rubber wheel 4; sleeve the grinding wheel 12 on the grinding wheel shaft 10 and screw into the grinding wheel baffle 11 to fix the grinding wheel;

[0028] (2) Loading of the grinding mechanism: The pressure of the sample coated on the rubber wheel 4 on the grinding wheel 12 is provided by the weight 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com