Apparatus and method for detecting abrasion resistance of garment collar and cuff

A detection device and detection method technology, applied in the direction of measuring devices, testing wear resistance, strength characteristics, etc., can solve the problem of long test cycle, large fluctuation of test results, no wear resistance of collars and cuffs, etc. problem, to achieve the effect of short detection period, simple structure and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

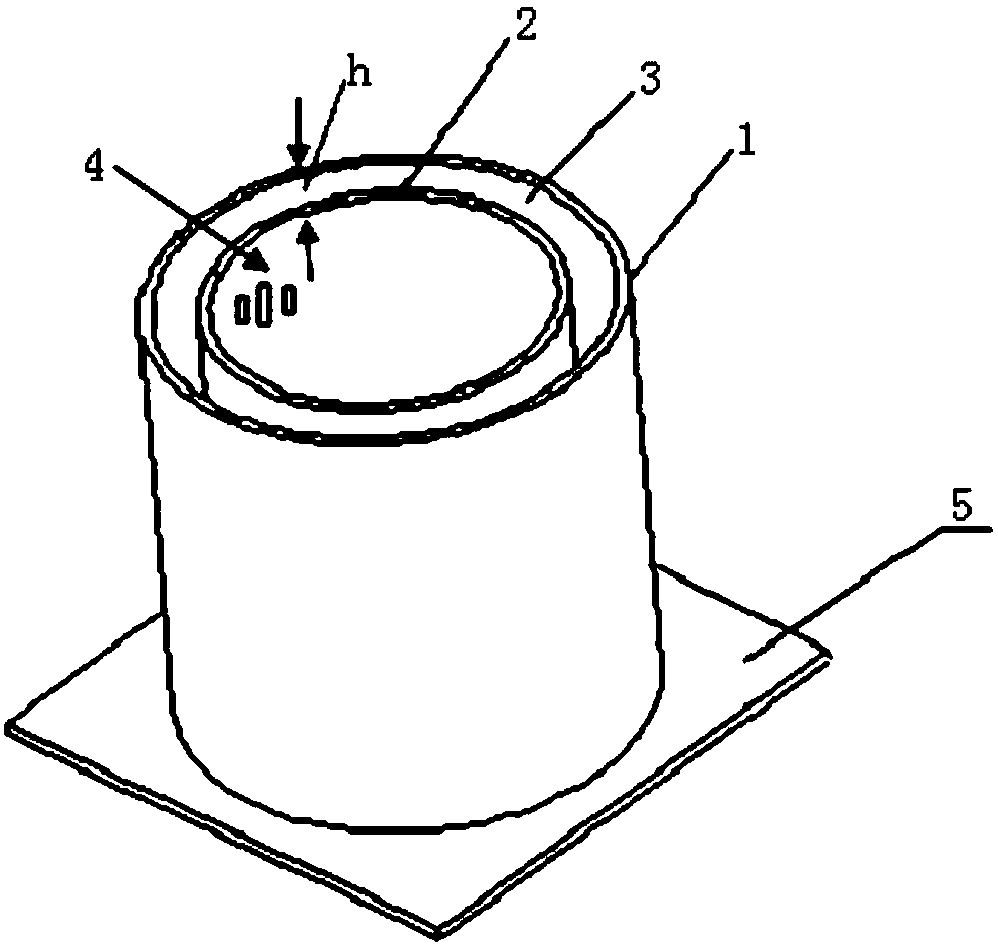

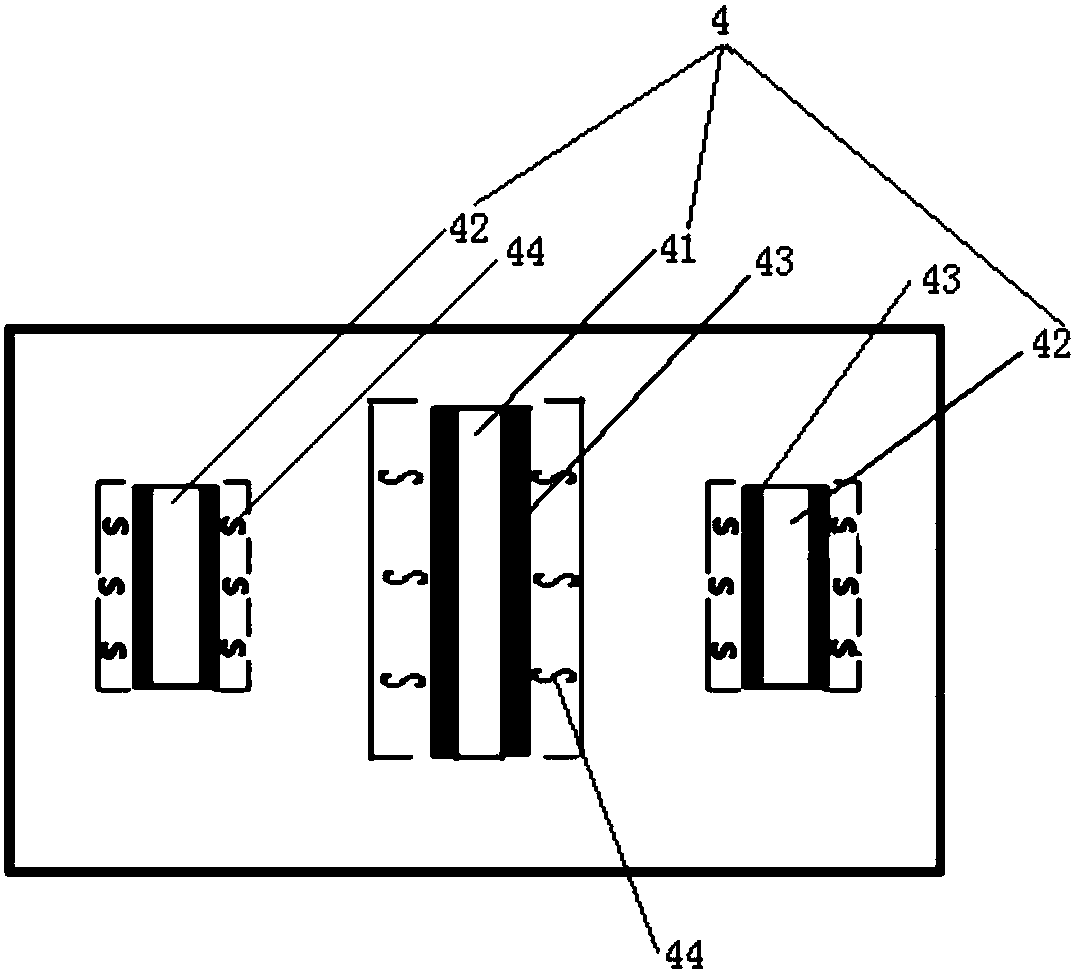

[0028] figure 1 with figure 2 These are respectively the structural schematic diagram of the detection device for clothing collar and cuff wear resistance of the present invention and the structural schematic diagram of the detection hole group of the clothing collar and cuff wear resistance detection device.

[0029] Such as figure 1 As shown, the detection device for the wear resistance of the clothing collar and cuffs of the present invention includes an outer tube 1 and an inner tube 2 rotatably arranged in the outer tube 1. An annular space 3 is formed between the inner tube 2 and the outer tube 1. A plurality of detection hole groups 4 are provided on the side wall of 2 along the circumferential direction.

[0030] Specifically, the outer cylinder 1 is a hollow cylindrical cylinder. The outer cylinder 1 includes a side wall and a bottom connected to the lower end of the side wall. The inner cylinder 2 has the same structure as the outer cylinder 1. It is also a hollow cylind...

Embodiment approach 2

[0040] Such as figure 1 with figure 2 As shown, the present invention provides a method for detecting abrasion resistance of clothing collars and cuffs, which is implemented using the clothing collar and cuff abrasion resistance detection device of the first embodiment, wherein the clothing collar and cuffs The structure, working principle and beneficial effects of the wear resistance detection device are the same as those in the first embodiment, and will not be repeated here. The method for detecting abrasion resistance of the clothing collar and cuffs includes the following steps:

[0041] A) Put the clothing to be tested in the inner tube 2, and pass the collar of the clothing to be tested and the cuffs of the clothing to be tested from the testing hole group 4 out of the inner tube 2 to the annular space 3;

[0042] B) Put the washing liquid in the annular space 3 and start the inner tube 2 so that the inner tube 2 rotates in a clockwise-counterclockwise cycle relative to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com