Desulfurization and denitrification granular activated carbon strength evaluation method

A granular activated carbon, desulfurization and denitrification technology, applied in the direction of strength characteristics, testing material strength by applying repeated force/pulsation force, testing wear resistance, etc., can solve the problems of reducing coal blending costs, small sampling volume, and heavy workload. Achieve the effects of reducing system errors, reducing analysis steps, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

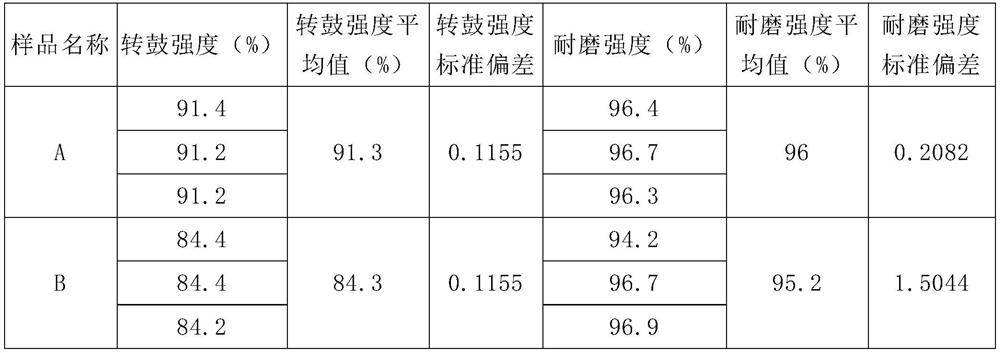

[0032] For the unknown desulfurization and denitrification granular activated carbon sample A and sample B, randomly weigh 1kg ± 0.005kg (accurate to 1g), respectively, and use the above-mentioned coke 1 / 4 Micomb drum strength test equipment to put the weighed samples into In the drum, set the drum to rotate at a speed of 25r / min for 400 revolutions, then stop the rotation, and let it stand for 1 to 2 minutes; sieve the desulfurization and denitrification granular activated carbon after rotation with a round hole sieve with a diameter of 5.6mm, and the measured value is greater than The weight of the desulfurization and denitrification granular activated carbon sample of 5.6 mm, and calculate the drum strength of the desulfurization and denitrification granular activated carbon sample; sample A and sample B were respectively tested in three parallel samples, and the results of the drum strength are shown in Table 1;

[0033] At the same time, GB / T 30202.3-2013 "Test method for ...

Embodiment 2

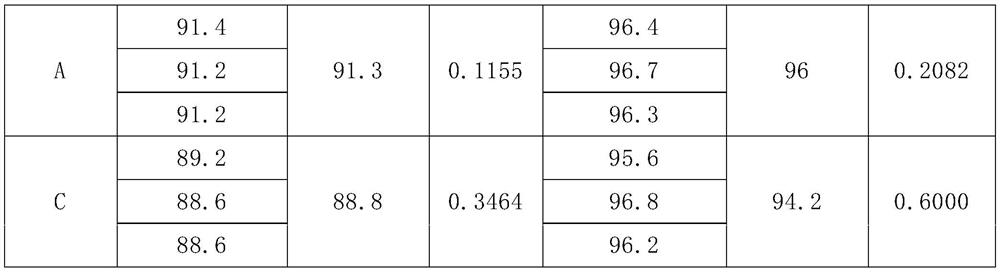

[0038] For the unknown desulfurization and denitrification granular activated carbon sample A and sample C, randomly weigh 1kg ± 0.005kg (accurate to 1g), respectively, and use the above-mentioned coke 1 / 4 Micomb drum strength test equipment to put the weighed samples into In the drum, set the drum to rotate at a speed of 25r / min for 400 revolutions, then stop the rotation, and let it stand for 1 to 2 minutes; sieve the desulfurization and denitrification granular activated carbon after rotation with a round hole sieve with a diameter of 5.6mm, and the measured value is greater than The weight of the desulfurization and denitrification granular activated carbon sample of 5.6 mm, and calculate the drum strength of the desulfurization and denitrification granular activated carbon sample; sample A and sample C were respectively tested in three parallel samples, and the results of the drum strength are shown in Table 1;

[0039] At the same time, GC / T 30202.3-2013 "Test method for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com