Asphalt pavement loop type small accelerated abrasion instrument and using method thereof

A technology for accelerating wear of asphalt pavements, which is applied in the direction of instruments, scientific instruments, and testing wear resistance. It can solve the problems of deviation of attenuation law, difficulty in simulating contact and wear conditions, etc., and achieve reasonable structure, improve pavement anti-skid performance, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

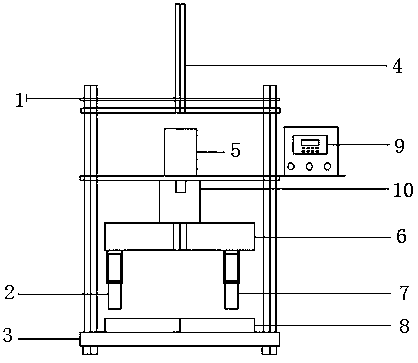

[0018] Embodiment 1: as figure 1 As shown, the asphalt pavement loop-type small-scale accelerated wear tester includes a frame pole 1, a bottom plate 3 fixed on the frame pole 1 and a driving device, the bottom plate 3 is provided with a groove, and the test piece 8 is arranged in In the tank, specimen 8 is an asphalt mixture splicing specimen. The driving device is connected to the rack rod 1 through the chute of the rack rod 1, the counterweight wheel 6 is connected to the driving device, and the test wheels are arranged on the bottom of the counterweight wheel 6 through shafts of different lengths to form the outer test wheel 2 and Inside test wheel 7. The drive device includes a motor 5 and a reducer 10, the drive motor 5 is electrically connected to the intelligent time control switch 9, the output shaft of the drive motor 5 is connected to the reducer, the reducer is connected to the counterweight wheel 6, and the drive motor 5 is connected to the screw 4 connect. The...

Embodiment 2

[0025] Embodiment 2: as figure 1 As shown, the asphalt pavement loop-type small-scale accelerated wear tester includes a frame pole 1, a bottom plate 3 fixed on the frame pole 1 and a driving device, the bottom plate 3 is provided with a groove, and the test piece 8 is arranged in In the tank, specimen 8 is an asphalt mixture splicing specimen. The driving device is connected to the rack rod 1 through the chute of the rack rod 1, the counterweight wheel 6 is connected to the driving device, and the test wheels are arranged on the bottom of the counterweight wheel 6 through shafts of different lengths to form the outer test wheel 2 and The inner test wheel 7; the drive device includes a motor 5 and a reducer 10, the drive motor 5 is electrically connected to the intelligent time control switch 9, the output shaft of the drive motor 5 is connected to the reducer, the reducer is connected to the counterweight wheel 6, and the drive Motor 5 is connected with screw rod 4. The wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com