Detection device of shaft seal test

A technology for detection devices and shaft seals, applied in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as accurate calculation of shaft seal wear, complex shaft seal wear, and complex wear environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

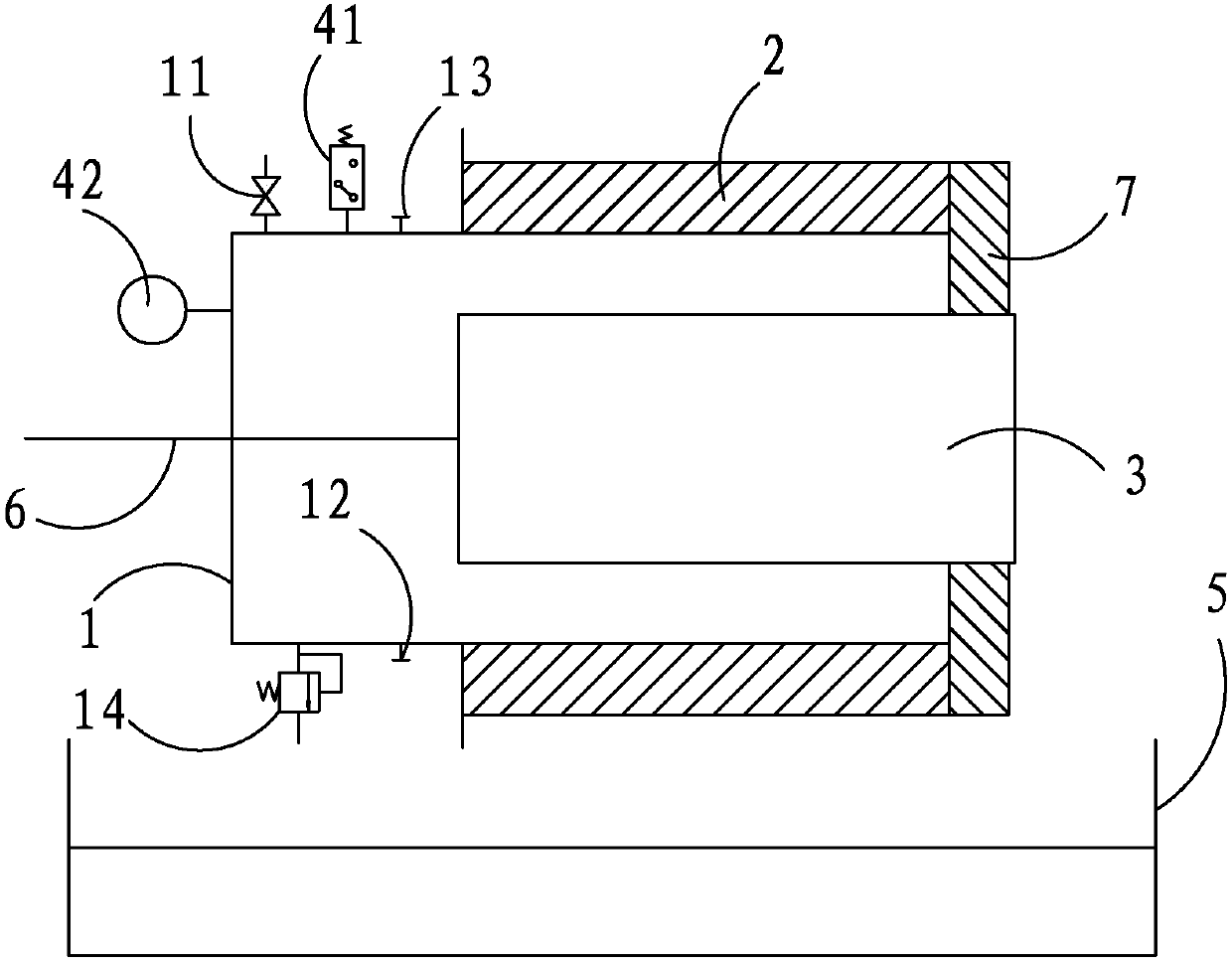

[0024] See attached figure 1 As shown, a detection device for shaft sealing test includes a test chamber 1 with a cavity inside and an opening at one end, a sealing tool 2 arranged at the open end of the test chamber 1, a dummy device installed in the test chamber 1 with horizontal rotation Axis 3, a detection element arranged on the test chamber 1 to detect the pressure in the chamber, and a water storage container 5 arranged under the test chamber 1, the test chamber 1 is provided with a water inlet 11 and a water outlet 12, sealed A shaft seal 7 to be tested is arranged between the tooling 2 and the dummy shaft 3 , and the dummy shaft 3 passes through the shaft seal 7 . Through the test chamber 1 simulating the rotational friction between the dummy shaft 3 and the shaft seal 7 under different water pressure conditions underwater, the wear of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com