Machine for testing wear resistance of printing ink

A wear resistance and testing machine technology, applied in the direction of testing wear resistance, etc., can solve the problems of misjudgment of manual observation method, easy to produce errors, manual observation method cannot be implemented concretely, etc., and achieve the effect of avoiding misjudgment and avoiding errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

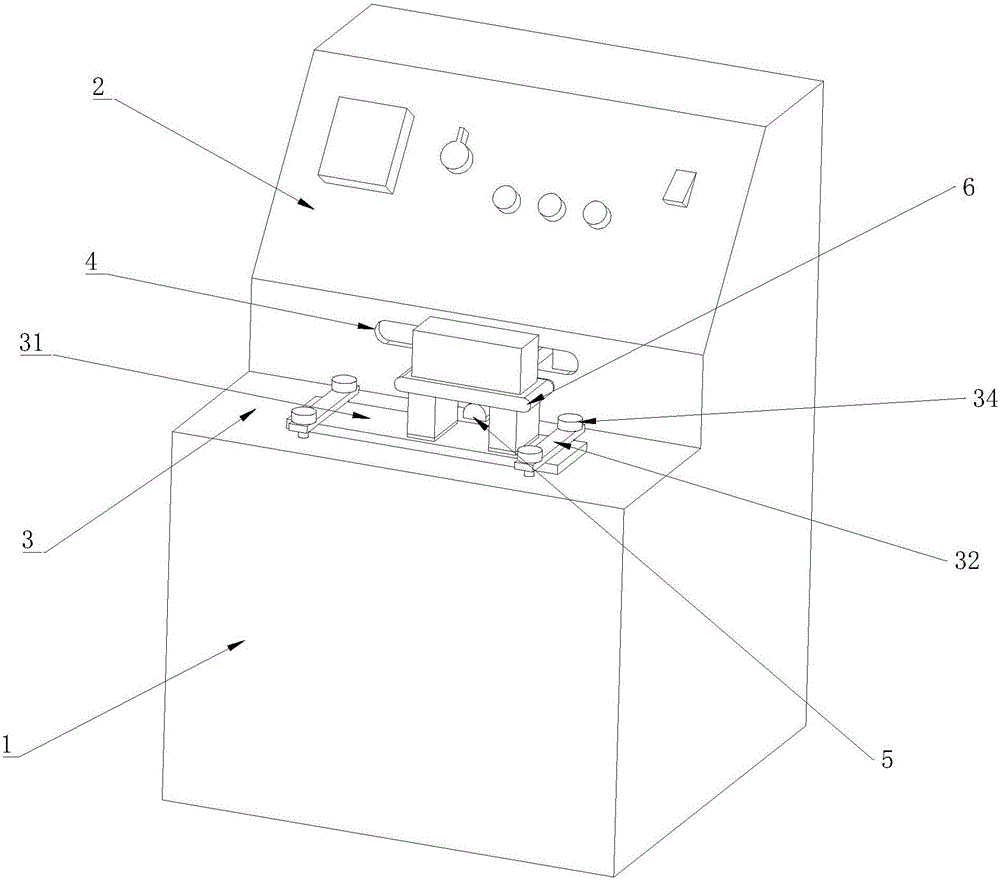

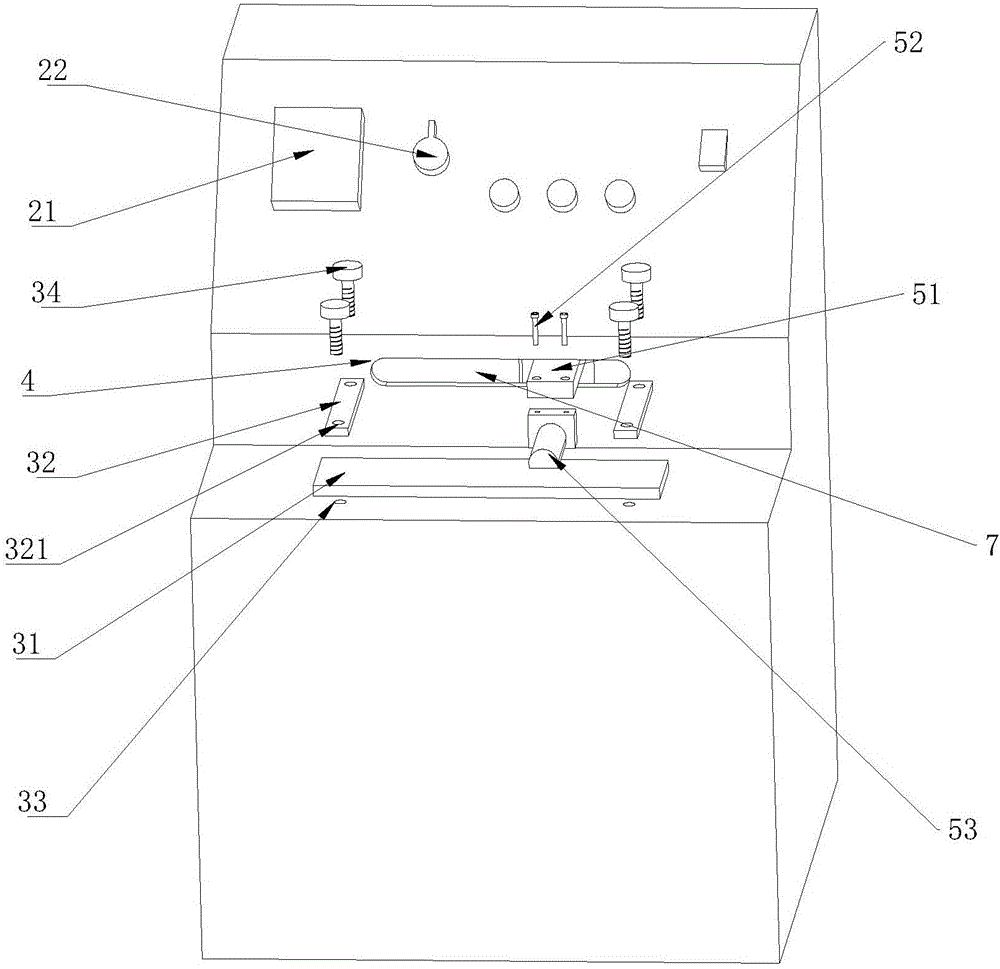

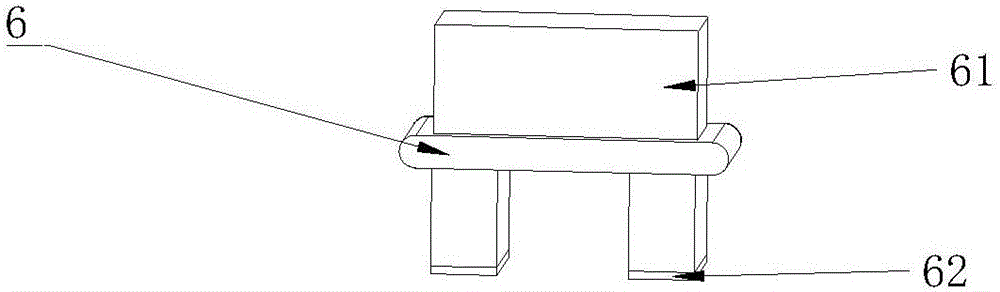

[0016] refer to figure 1 , figure 2 , a kind of ink abrasion resistance testing machine of the present invention, comprises machine platform 1, and described machine platform 1 is provided with motor and transmission device inside, and described machine platform 1 is also provided with control panel 2 and test stand 3, and described test The table 3 is provided with a paper strip fixing plate 31, and the left and right ends of the fixing plate 31 are respectively provided with a bead 32, and the front and rear ends of the bead 32 are provided with small holes 321, and the test bench 3 is also provided with 4 a threaded hole 33 and four fastening knobs 34, the lower end of the fixing knob 34 is provided with thread and passes through the small hole 321 and the threaded hole 33 to fit, the machine table is on the control panel 2 and the There is a slot 4 between the test benches 3, and an extension rod 5 is arranged in the slot 4. The extension rod 5 is driven by the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com