A method for detecting the wear condition of an automobile continuously variable transmission

A technology of continuously variable transmission and detection method, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problem of affecting the establishment of lubricating oil film on the surface of friction pairs, affecting the service life of metal belts and pulleys in CVT, and affecting CVT power transmission. efficiency and other issues, to achieve the effect of low cost, uniform size and good fluorescence performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Specific embodiment one: the preparation method of fluorescent nanosensor in this embodiment is characterized in that the method comprises the following steps:

[0032] 1. Weigh 0.5g of EDTA, add 2ml of nitric acid with a concentration of 0.5mol / L (the purpose is to dissolve EDTA), then add 4ml of oleic acid and 10ml of octadecene, and mix ultrasonically at room temperature to form a uniform mixed solution;

[0033] 2. Put the mixed solution obtained in step 1 into a high-temperature reactor, and then put the reactor into an oven for 10 hours;

[0034] 3. Set the solution obtained in step 2 as A, take 15ml of solution A, pour 2 times the volume of methanol (for purification), and then perform centrifugation, and take the supernatant after standing still, which is solution B;

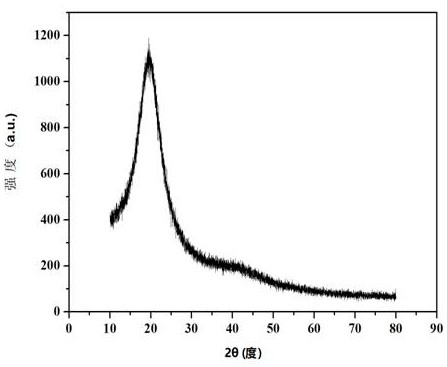

[0035] 4. Put the solution B obtained in step 3 under purple light to irradiate, showing blue light;

[0036] 5. Collect the same amount of lubricating oil used in five sets of CVTs of the same m...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment differs from Embodiment 1 in that: the power of the ultrasonic mixing in Step 1 is 60-80W. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the reaction temperature in step 2 is 200°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com