Microvibration Simulation Experimental Device for Overhead Conductors

A technology for simulating experimental devices and overhead wires. It is used in measurement devices, vibration testing, and testing of machine/structural components. It can solve problems such as difficulty in simulating high-voltage power transmission states and inappropriate use of high-voltage transmission wires, reducing friction and heat dissipation. Wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

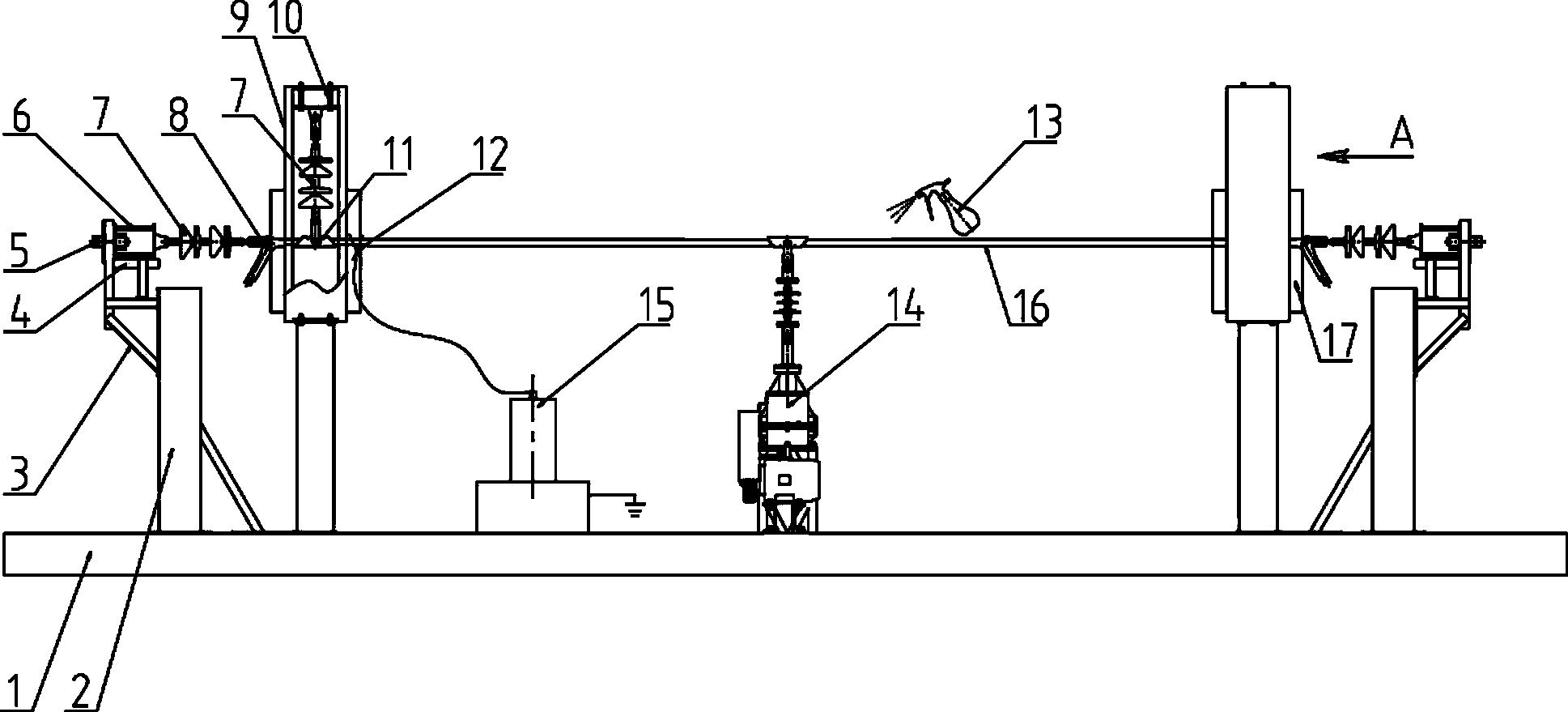

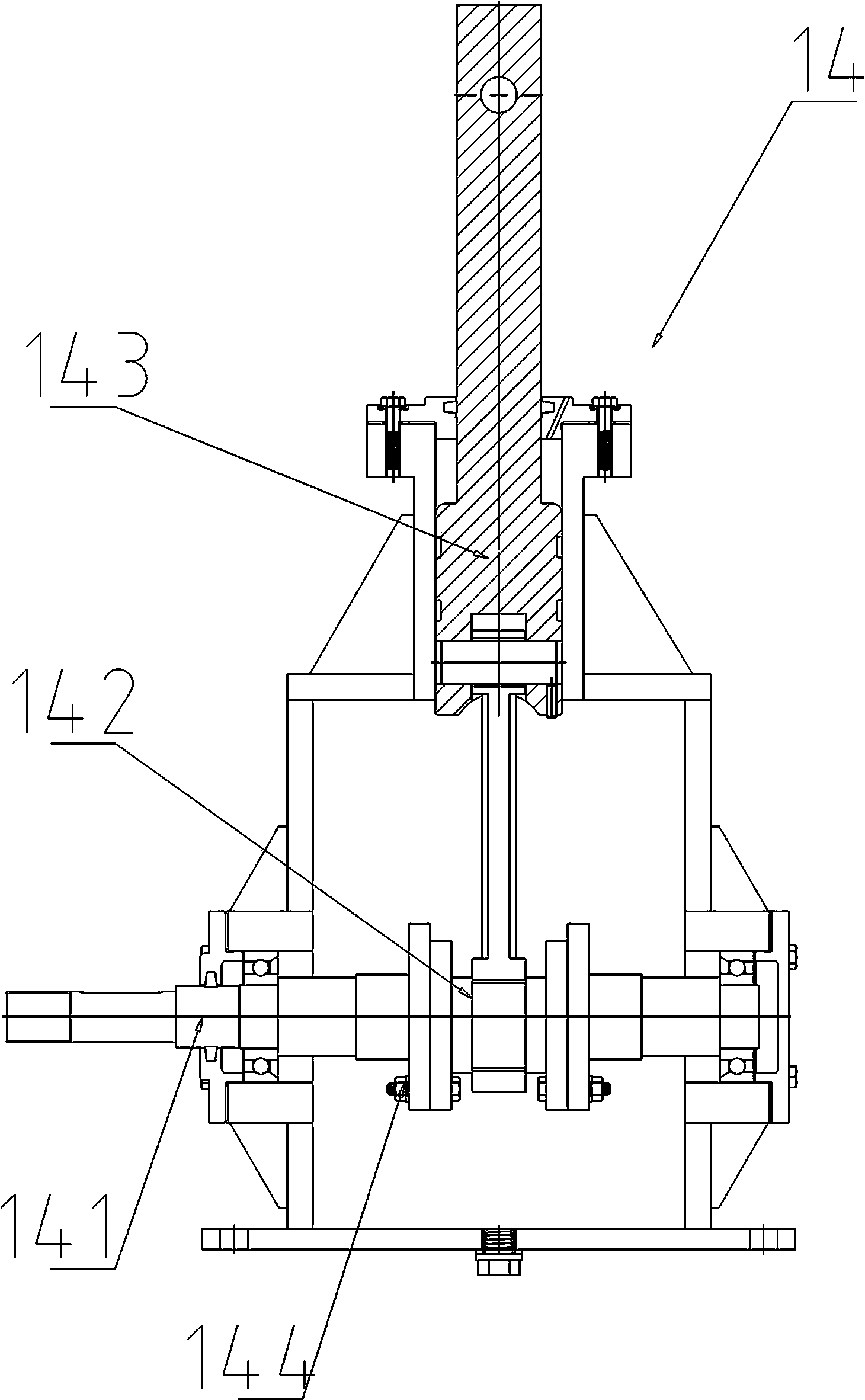

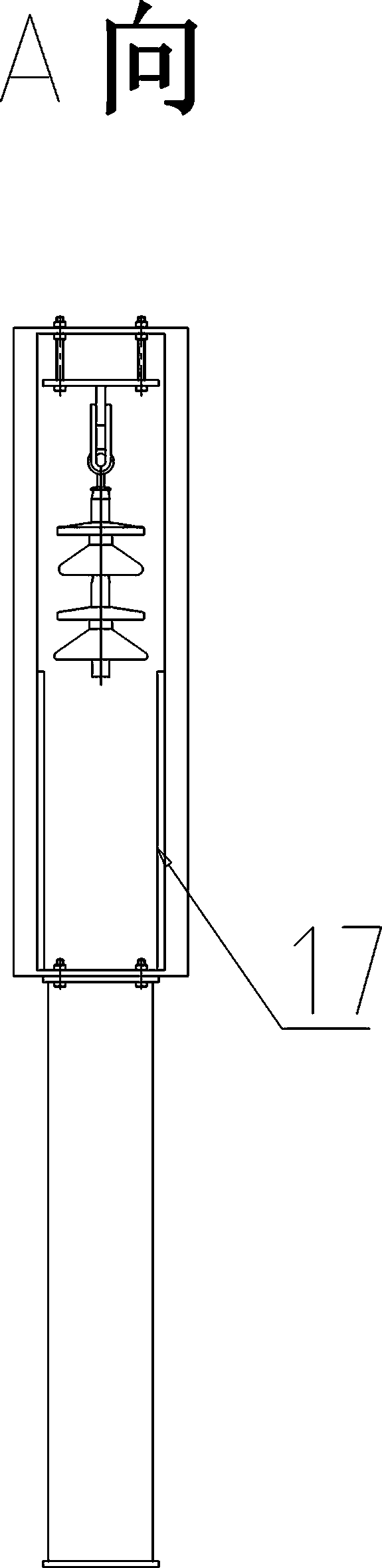

[0030] Such as figure 1 Among them, an overhead wire microvibration simulation experiment device includes a base 1, a tensioning device is provided at both ends of the upper end surface of the base 1, and the two ends of a wire 16 are connected to the tensioning device through a tension clamp 8 and an insulator 7, and the wire 16 is connected to the tensioning device. There is also a pressure sensor between the two ends and the tensioning device; in this example, the pressure sensor is a pressure sensor made of a piezoelectric element, which is installed on the ball-end hanging ring between the tension clamp 8 and the insulator 7 .

[0031] In the optimized scheme, in the tensioning device, the tensioning support frame 2 is fixedly connected to the base 1, and the diagonal brace 3 runs through the tensioning support frame 2 to connect with the tensioning bracket 4 located outside the tensioning support frame 2, and the tension The bracket 4 is connected with the adjustment fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com