A continuous testing equipment for the abrasion of short fiber radially oriented tread rubber

A test equipment and short fiber technology, which is applied in the field of continuous test equipment, can solve the problems of small load and rotating speed, difficulty in rubber material wear test, single test conditions, etc., and achieve the effect of safe use, high test efficiency and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

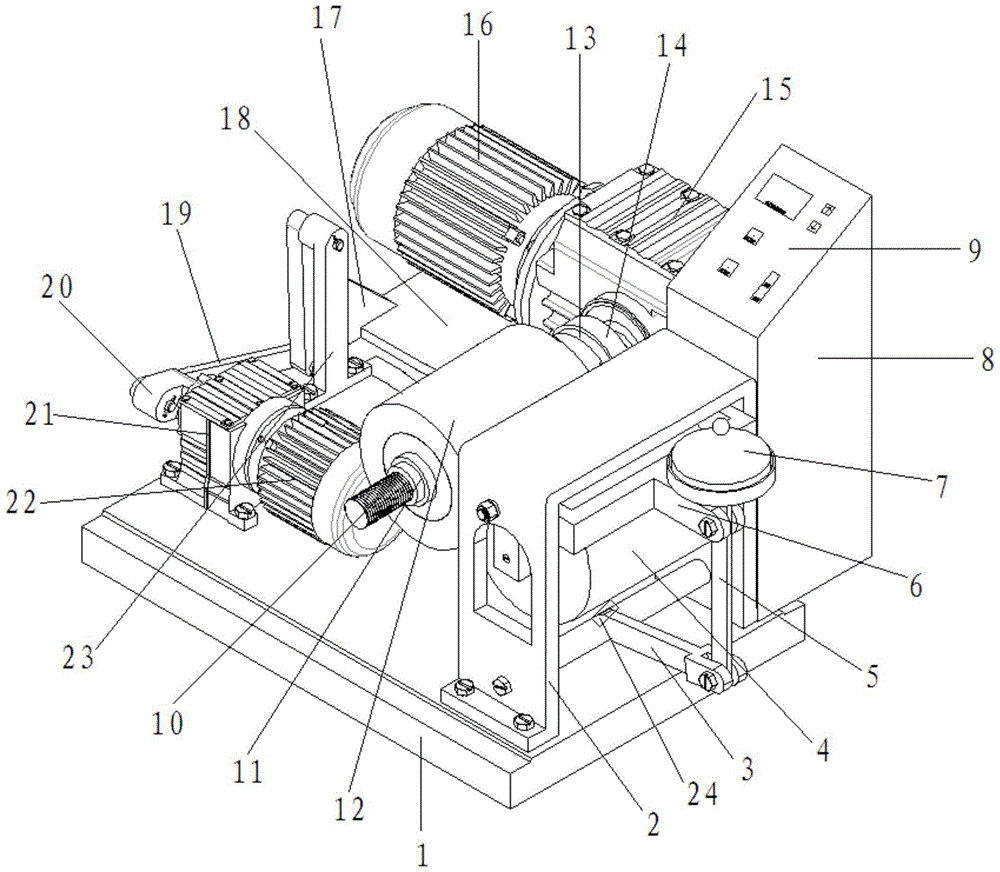

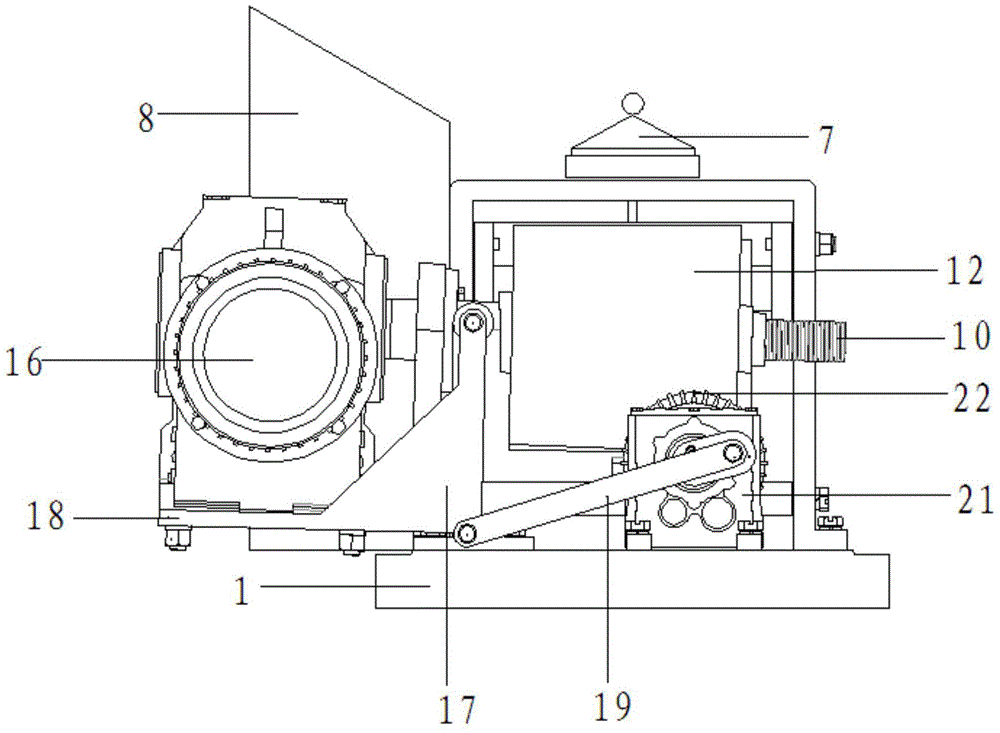

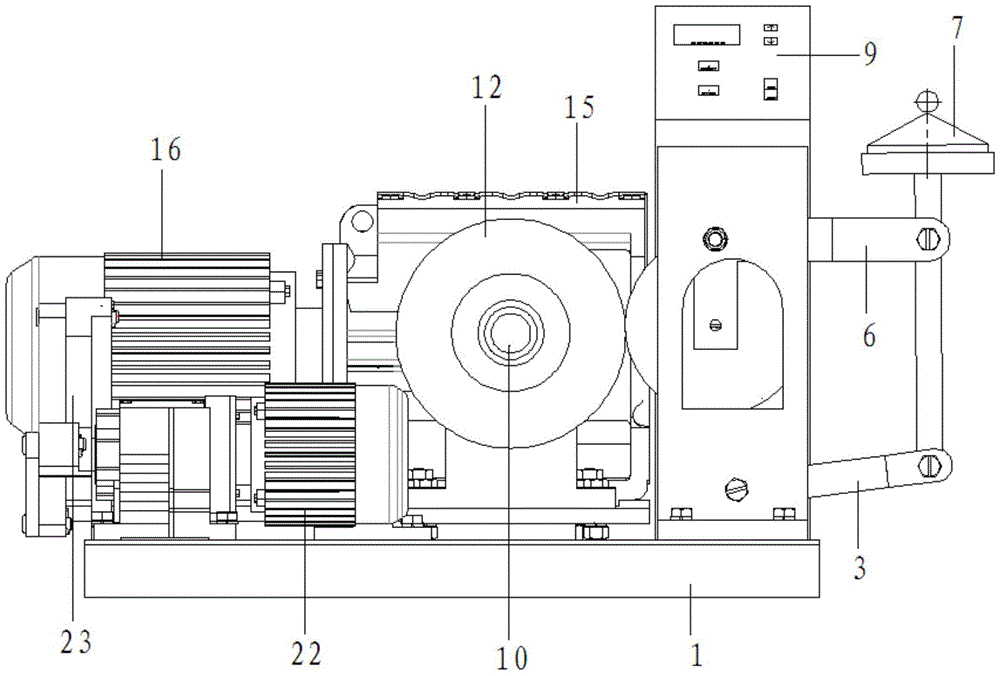

[0022] The main structure (such as figure 1 (shown) includes four parts: grinding mechanism, rotary mechanism, angle adjustment mechanism and electric control box. The grinding mechanism specifically includes base 1, fixed bracket 2, angle adjustment bracket 3, rubber wheel 4, weight bracket 5, rubber Wheel bracket 6, weight 7 and balance weight 24, the slewing mechanism specifically includes grinding wheel shaft 10, grinding wheel baffle plate 11, grinding wheel 12, bearing 13, grinding wheel shaft support 14, No. 1 reducer 15 and No. 1 motor 16, angle adjustment mechanism It specifically includes rocker 17, motor base 18, connecting rod 19, crank 20, No. II reducer 21, No. II motor 22 and rocker bracket 23, and the electric control box specifically includes control box 8 and control panel 9; the inner hollow frame The fixed bracket 2 of the overall structure is fixed on the base 1 by bolts, the radial direction of the rubber wheel 4 and the rubber wheel bracket 6 is fixed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com