Polyurea based polyol, preparation method, polyether shoe sole stock solution and preparation method

A polyether polyol and polyol technology, which is applied to shoe soles, footwear, applications, etc., can solve the problems of increasing construction amount, affecting the service life of shoe soles, poor water resistance, etc., and achieving the effect of good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of polyurea-based polyols:

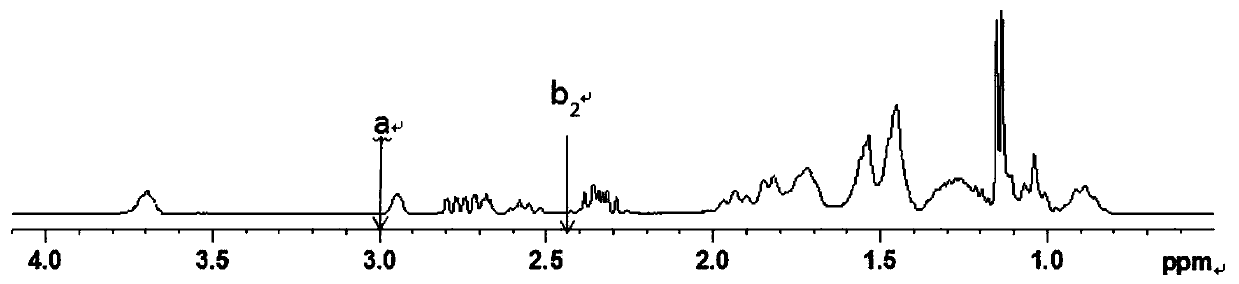

[0058] equipped with stirrer, thermometer and N 2 Add 12.68 parts of 4,4'-diaminodicyclohexylmethane to the reaction kettle of the air pipeline, and then add 15.69 parts of butyl glycidyl ether dropwise to the reaction kettle under stirring at 60°C. The reaction was continued for 4 h under the protection of nitrogen to obtain a polyol containing secondary amino groups. Then equipped with stirrer, thermometer and N 2 Add 5.07 parts of HDI to the reaction kettle of the air pipeline, and then slowly add the above-mentioned polyol containing secondary amino groups dropwise into the reaction kettle at 30°C with a stirring speed of 100 r / min, and continue the reaction for 4 hours after the dropwise addition is completed, to obtain Polyurea-based polyol (nuclear magnetic structure analysis such as figure 1 , δ=2.4 (a place), 3.0 (b place) epoxy group peak disappears, δ=2.9 ether bond peak appears, indicating the generation of polyure...

Embodiment 2

[0068] Preparation of polyurea-based polyols:

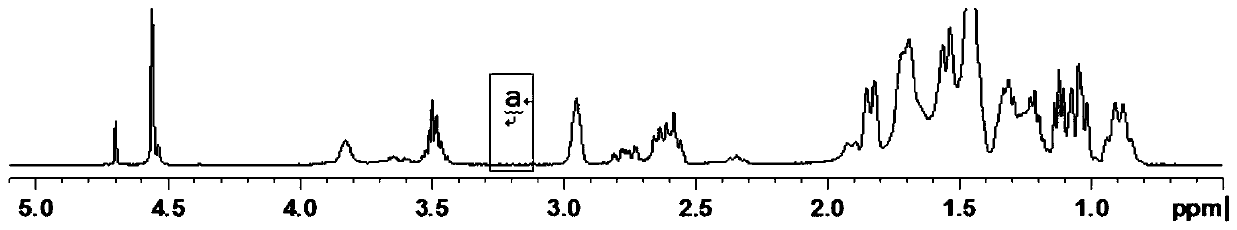

[0069] equipped with stirrer, thermometer and N 2 Add 33.51 parts of polyetheramine 8100 to the reaction kettle in the gas pipeline, then add 33.85 parts of isopropyl glycidyl ether dropwise into the reaction kettle under stirring at 40°C, and continue the reaction for 3 hours under the protection of nitrogen after the dropping , to obtain polyols containing secondary amino groups. Then equipped with stirrer, thermometer and N 2 Add 16.2 parts of IPDI to the reaction kettle of the air pipeline, and then slowly add the above-mentioned polyol containing secondary amino groups dropwise into the reaction kettle at 15°C with a stirring speed of 300r / min, and continue the reaction for 3 hours after the dropwise addition is completed, to obtain Polyurea-based polyol (nuclear magnetic structure analysis such as figure 2 , δ=2.4, 3.0 place epoxy group peak disappears, δ=2.9 place ether bond peak appears, illustrates the generation of ...

Embodiment 3

[0079] Preparation of polyurea-based polyols:

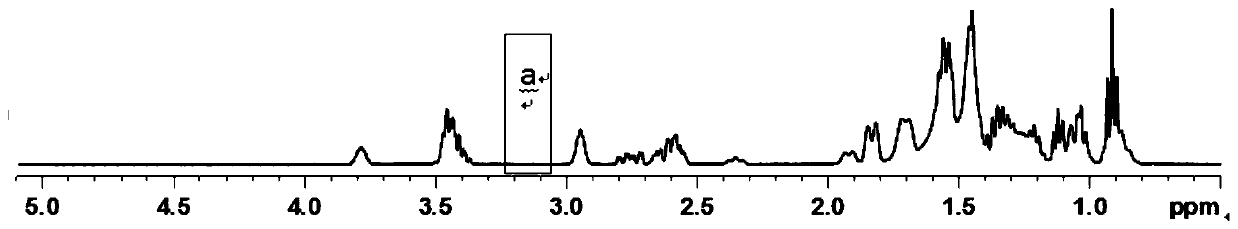

[0080] equipped with stirrer, thermometer and N 2 Add 16.76 parts of polyetheramine 8100 and 4.38 parts of isophorone diamine to the reaction kettle in the gas pipeline, and then add 36.76 parts of octyl glycidyl ether dropwise to the reaction kettle under stirring at 50 °C. , and continued to react for 3.5 h under the protection of nitrogen to obtain polyols containing secondary amino groups. Then equipped with stirrer, thermometer and N 2Add 10.09 parts of HMDI and 8.55 parts of IPDI into the reaction kettle of the gas pipeline, and then slowly add the above-mentioned polyol containing secondary amino groups into the reaction kettle at 25°C with a stirring speed of 250r / min, and continue the reaction after the addition is completed 3.5h, obtain polyurea-based polyol (nuclear magnetic structure analysis such as image 3 , δ=2.4, the epoxy group peak at 3.0 disappeared, and the ether bond peak appeared at δ=2.9, indicating the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com