Rotary multi-contact corrosive wear testing apparatus

A technology of corrosion and wear test and test device, which is used in measurement devices, weather resistance/light resistance/corrosion resistance, and wear resistance testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

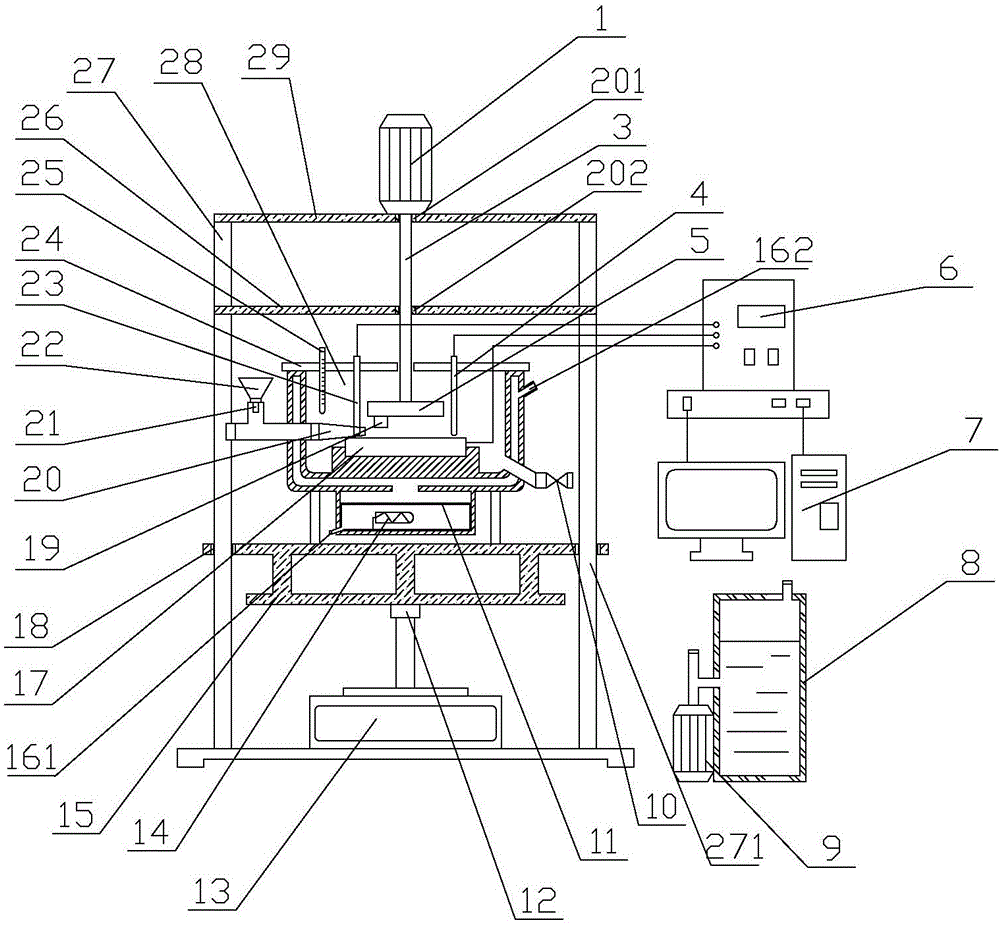

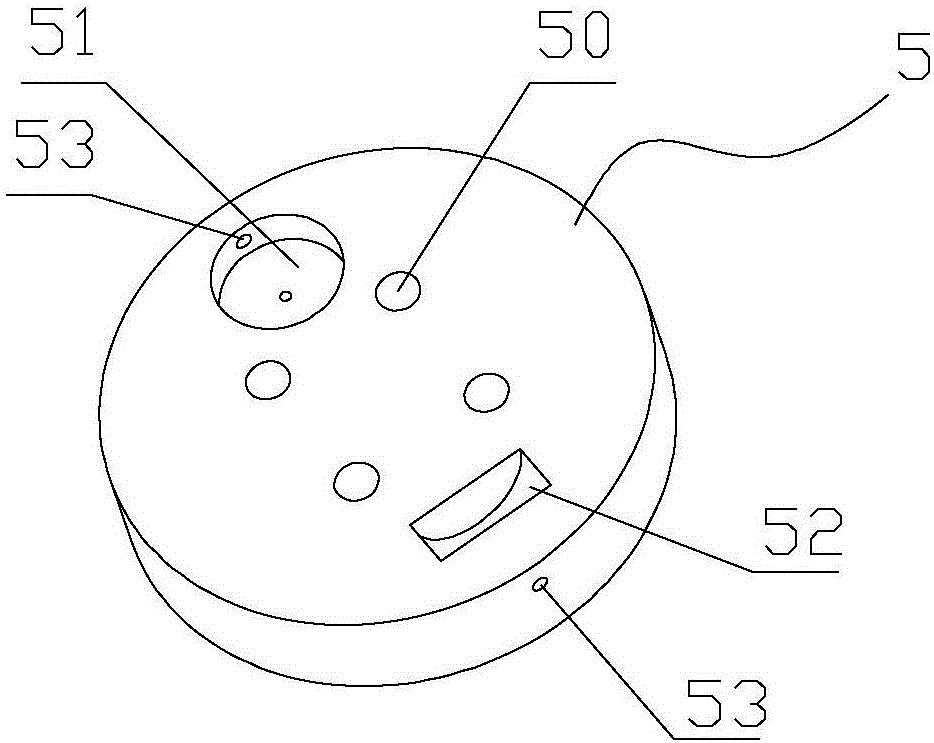

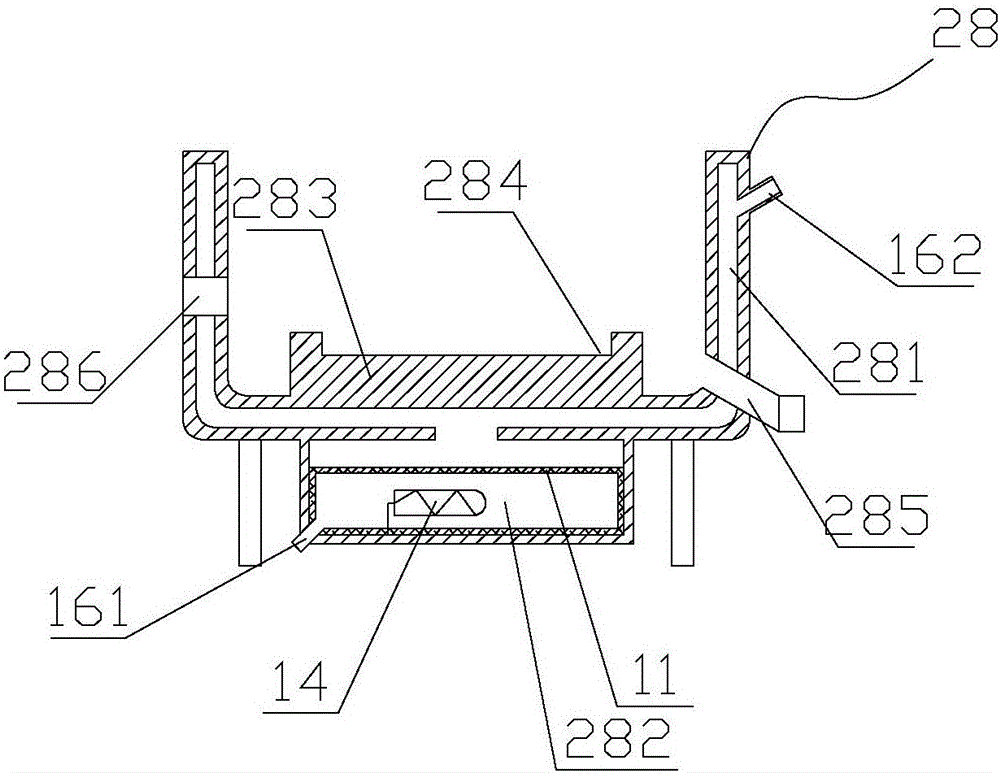

[0054] Such as figure 1 As shown, the present invention provides a kind of rotary multi-contact corrosion wear test device, and described test device comprises following parts:

[0055] Electrochemical test system, described electrochemical test system comprises working electrode 17, reference electrode 23 and auxiliary electrode 4; This electrochemical test system adopts three-electrode system to carry out corrosion rate test, can the electric current, polarization in the friction corrosion process The wear rate under the synergistic effect of friction and corrosion is deduced by testing the curves, etc., and the wear performance is characterized by the weight loss method.

[0056] Reaction container, described reaction contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com